Coating for flooring materials and flooring material

A technology for floor materials and coatings, applied in the direction of conductive coatings, polyester coatings, coatings, etc., can solve the problem of insufficient balance of water resistance, abrasion resistance, transparency, surface smoothness and softness, and impact resistance. Environmental degradation, poor adhesion and other problems, to achieve a good working environment, high-order balance of impact resistance, excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

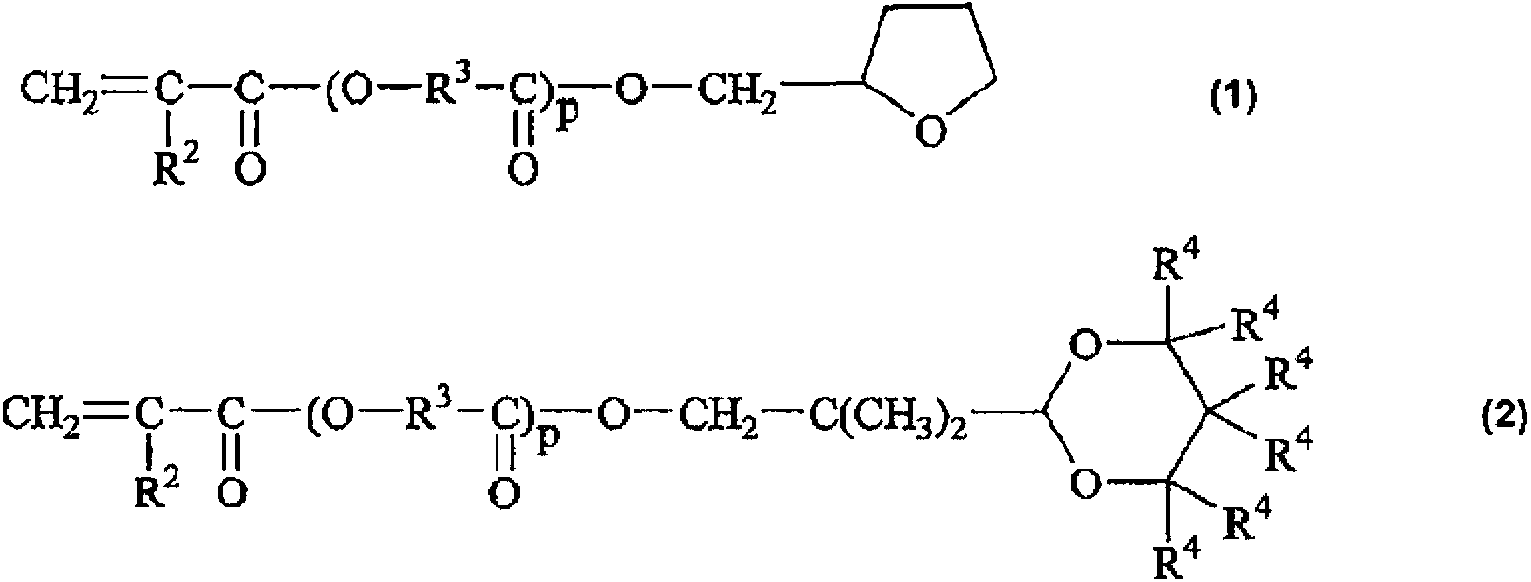

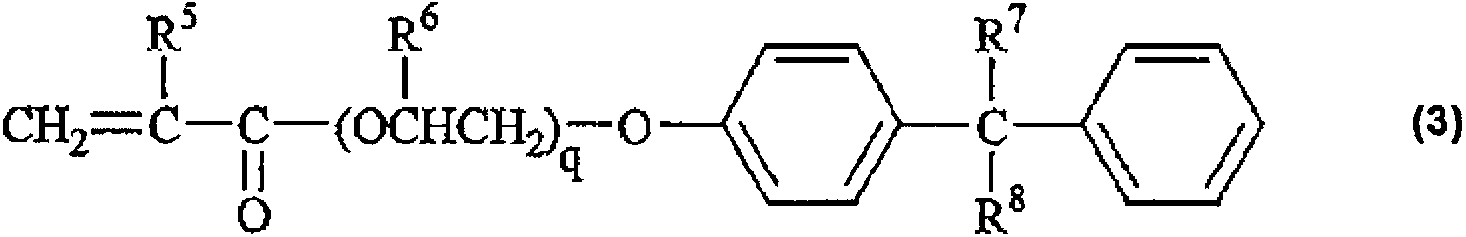

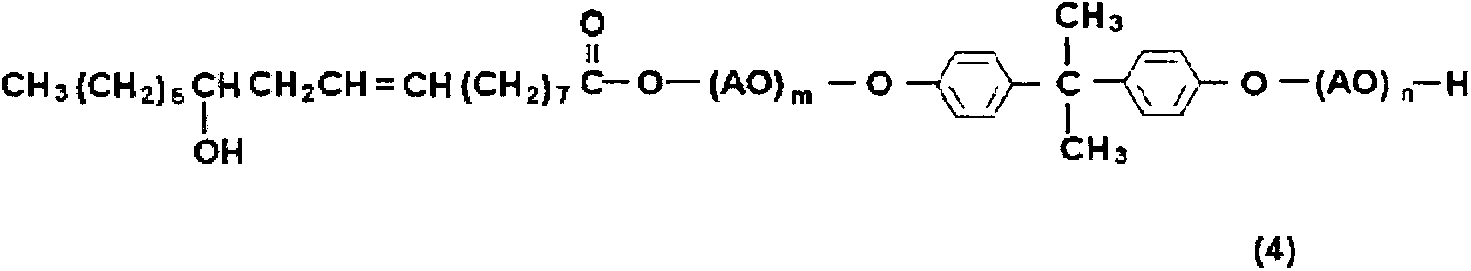

Method used

Image

Examples

Embodiment 1~51

[0357] Examples 1-51, Comparative Examples 1-6

[0358] In the compounding ratio (parts by mass) shown in the following Tables 1 to 15, put components (a) to (b) in a container equipped with a stirrer, stir well at room temperature, and then add component (c) and stir Then, when the liquid temperature becomes normal temperature, component (d) is added, and after stirring sufficiently so that no solid remains, components (e) and (f) are added and stirred to obtain a paint. The viscosity (mPa·s) at 25° C. of the obtained adhesive composition was measured. That is, the viscosity at 25° C. was measured using a portable digital viscometer TVC-7 rotational viscometer (Toki Kogyo Co., Ltd.) using an appropriate spindle (No. 0 to No. 5) corresponding to the viscosity. The results are shown together in the table.

[0359] Next, on each table and the various specific floor substrates (dimensions: 150 mm x 25 mm x thickness 1 mm) shown below. Coating was applied by spin coating (coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com