Extrusion parts of fish bone separation device

A separation device and technology for extruding parts, applied to presses, processing fish, slicing fish, etc., can solve the problems of low meat harvesting rate, poor extrusion effect, complex structure, etc., and achieve improved meat harvesting efficiency, The effect of prolonging the service life and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

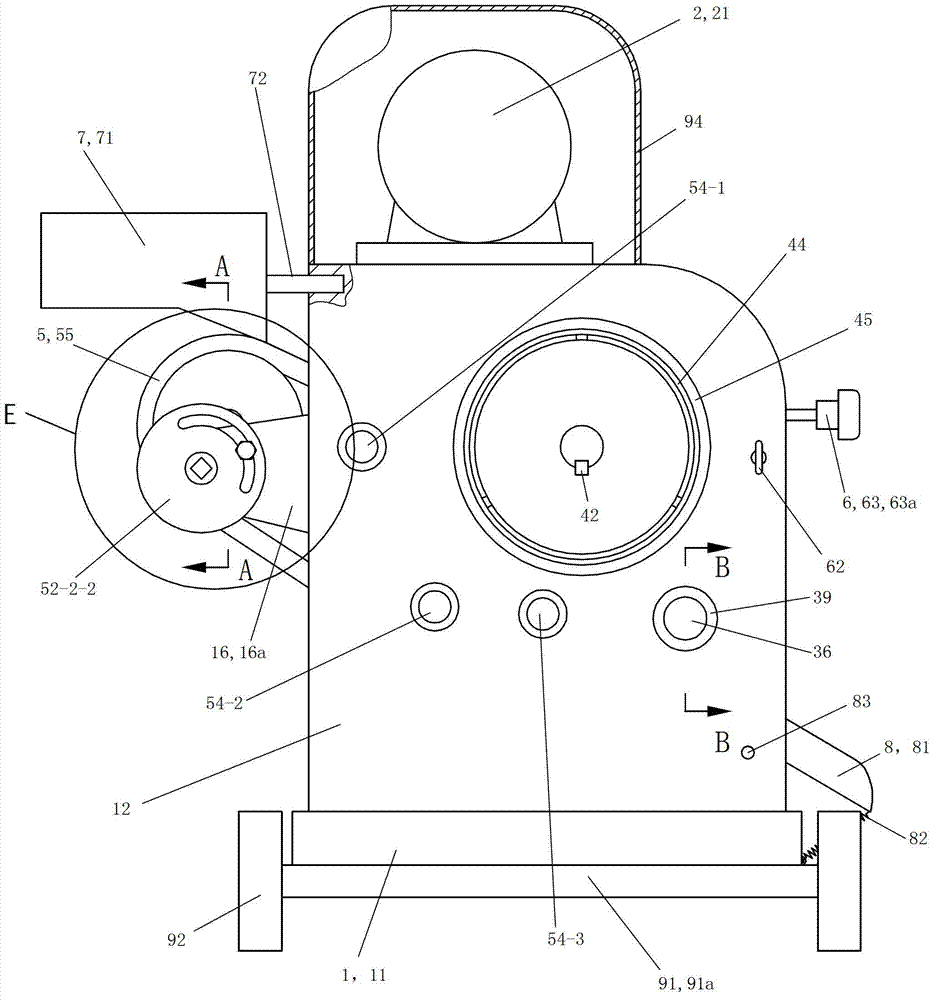

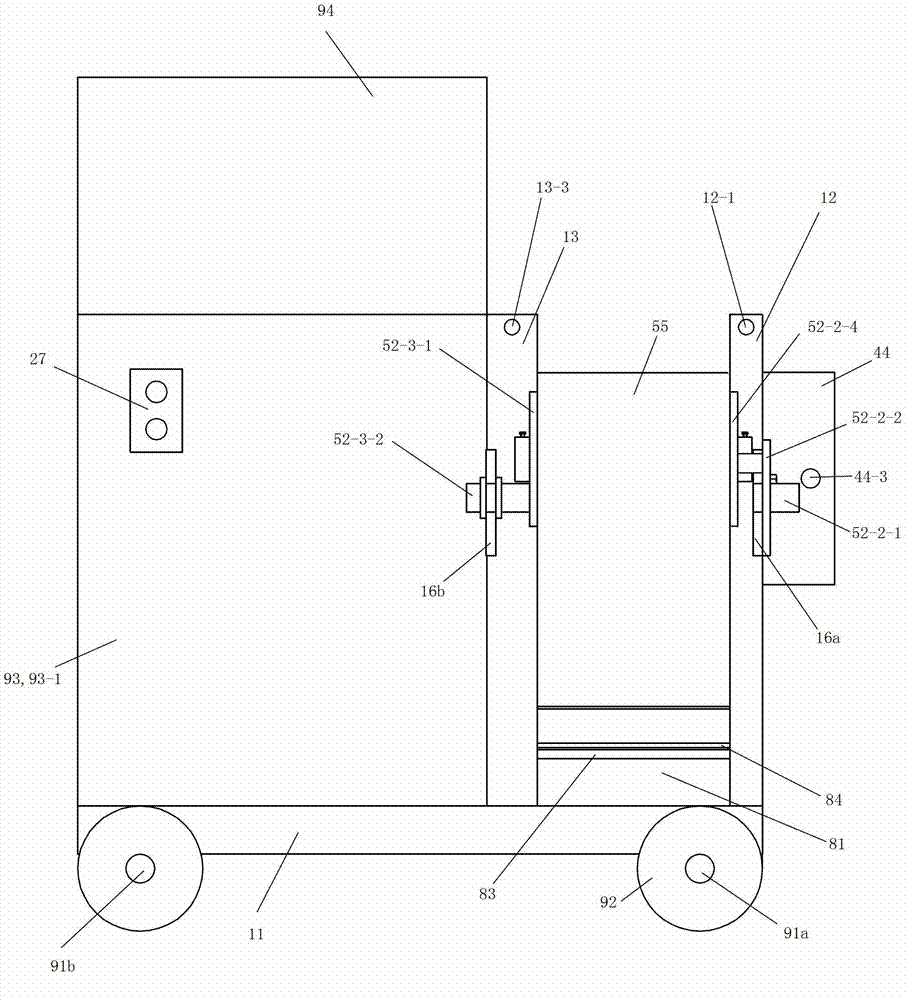

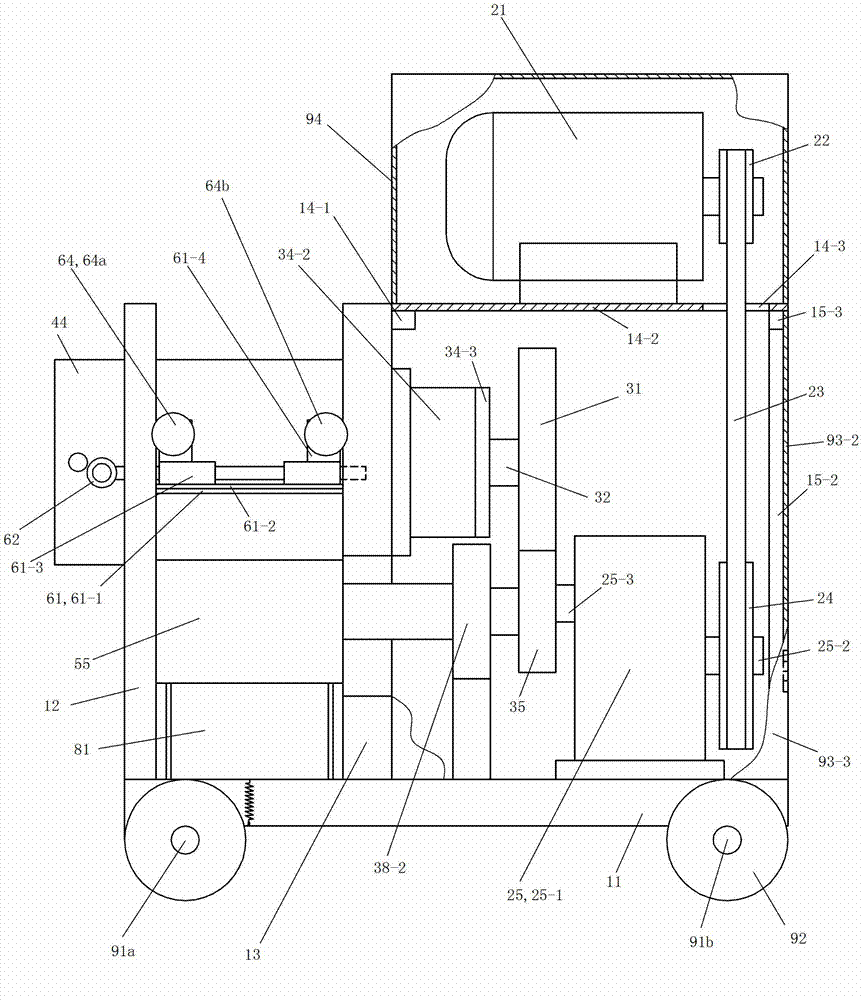

[0058] See figure 1 , Figure 5 , Figure 6 to Figure 8 and Figure 10 to Figure 14 , the extruding part of this embodiment includes a frame 1 and an extruding device 5 . The extruding device 5 is composed of a positioning bolt 51 , an adjusting roller assembly 52 , a driving roller 53 , an intermediate roller assembly 54 and an extruding belt 55 .

[0059] See figure 1 , The frame 1 is mainly composed of a base plate 11, a front side plate 12, a middle partition plate 13 and a roller support plate 16 all being steel parts.

[0060] See Figure 1 to Figure 5 , The bottom plate 11 is formed by welding and fixing a rectangular main body horizontally arranged and a frame plate vertically arranged around the main body from below.

[0061] See Figure 1 to Figure 4 , the front side plate 12 is a rectangular plate with a rounded upper right corner vertically arranged along the left and right directions, and the front side plate 12 is seated and welded on the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com