Processing method for improving quality of tobacco stem extract

A processing method and extraction technology, applied in tobacco, tobacco treatment, application, etc., can solve the problem that tobacco stems cannot be fully utilized, and achieve the effect of improving sensory quality and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

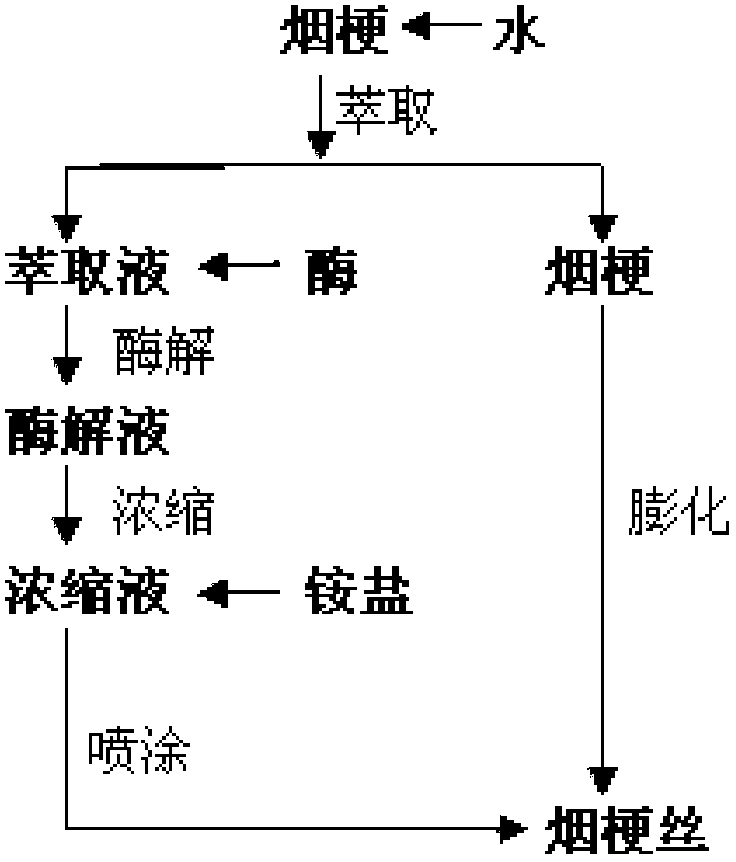

Method used

Image

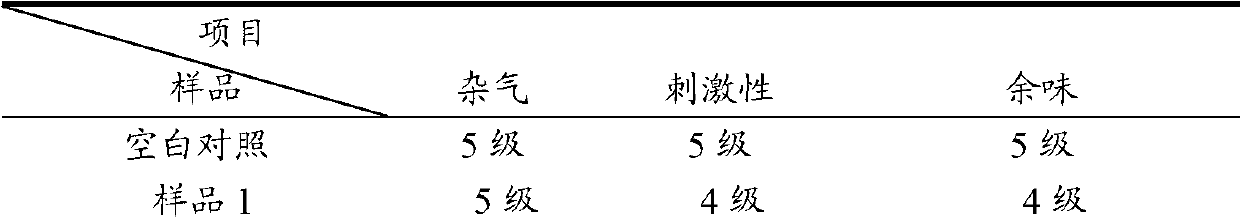

Examples

Embodiment 1

[0028] 1) Accurately weigh 100g of stem sticks, leaching with water for 50min at a material-to-liquid ratio of 1:6 and a temperature of 50°C, and filter to obtain tobacco stem extract.

[0029] 2) Enzymatic hydrolysis of the tobacco stem extract: add 0.3g of neutral cellulase with an activity of 100,000U / g to 100g of tobacco stem extract, 0.4g of pectinase with an activity of 50,000U / g, and an activity of 100,000U / g of papain 0.3g. The order of adding the enzyme preparations is as follows: add the neutral cellulase and pectinase and react for 1.5 hours at the same time, then add papain and react for 1.0 hours. The enzymatic hydrolysis conditions of the tobacco stem extract are: temperature 45°C, pH natural. After the enzymolysis is completed, the extract is subjected to enzyme inactivation treatment, and the enzyme inactivation conditions of the tobacco stem extract are: water bath inactivation, the temperature is 95-100° C., and the time is 10 minutes.

[0030] 3) Concentr...

Embodiment 2

[0043] 1) Accurately weigh 100g of stem sticks, leaching with water for 50min at a material-to-liquid ratio of 1:6 and a temperature of 50°C, and filter to obtain tobacco stem extract.

[0044] 2) Enzymatic hydrolysis of the tobacco stem extract: add 0.25g of neutral cellulase with an activity of 100,000U / g to 100g of tobacco stem extract, 0.5g of pectinase with an activity of 50,000U / g, and an activity of 100,000U / g of papain 0.2g. The order of adding the enzyme preparations is as follows: after neutral cellulase and pectinase are simultaneously added to react for 1.0 h, then papain is added to react for 1.0 h. The enzymatic hydrolysis conditions of the tobacco stem extract are: temperature 45°C, pH natural. After the enzymolysis is completed, the extract is subjected to enzyme inactivation treatment, and the enzyme inactivation conditions of the tobacco stem extract are: water bath inactivation, the temperature is 95-100° C., and the time is 10 minutes.

[0045] 3) Concen...

Embodiment 3

[0057] 1) Accurately weigh 100g of stem sticks, leaching with water for 50min at a material-to-liquid ratio of 1:6 and a temperature of 50°C, and filter to obtain tobacco stem extract.

[0058] 2) Enzymatic hydrolysis of the tobacco stem extract: Add 0.25g of neutral cellulase with an activity of 100,000U / g to 100g of tobacco stem extract, 0.4g of pectinase with an activity of 50,000U / g, and an activity of 100,000U / g of papain 0.3g. The order of adding the enzyme preparations is as follows: after neutral cellulase and pectinase are simultaneously added to react for 1.0 h, then papain is added to react for 1.0 h. The enzymatic hydrolysis conditions of the tobacco stem extract are: temperature 45°C, pH natural. After the enzymolysis is completed, the extract is subjected to enzyme inactivation treatment, and the enzyme inactivation conditions of the tobacco stem extract are: water bath inactivation, the temperature is 95-100° C., and the time is 10 minutes.

[0059] 3) Concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com