Formation method of drug coating and drug coating prepared by same

A technology of drug coating and drug molecules, applied in the field of medicine, can solve problems such as narrow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Solid particle mixture according to one embodiment of the present invention

no. 1 approach

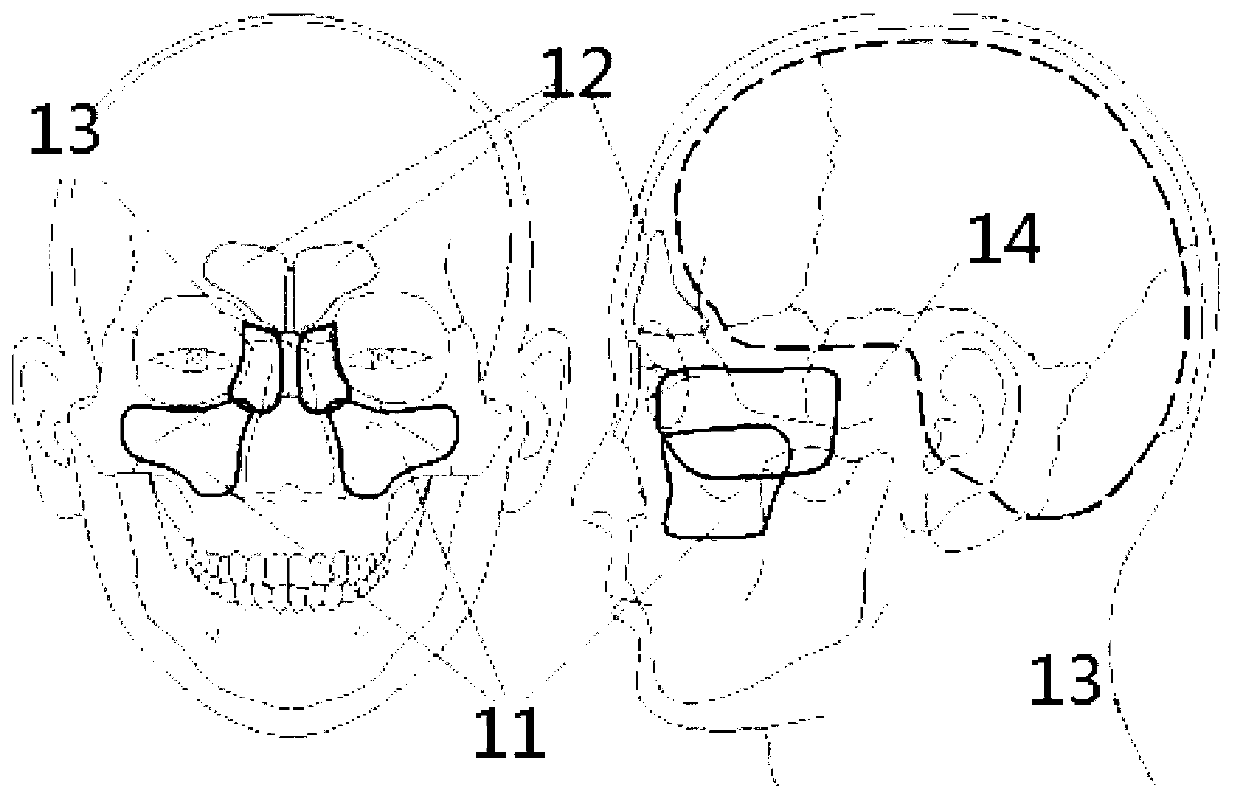

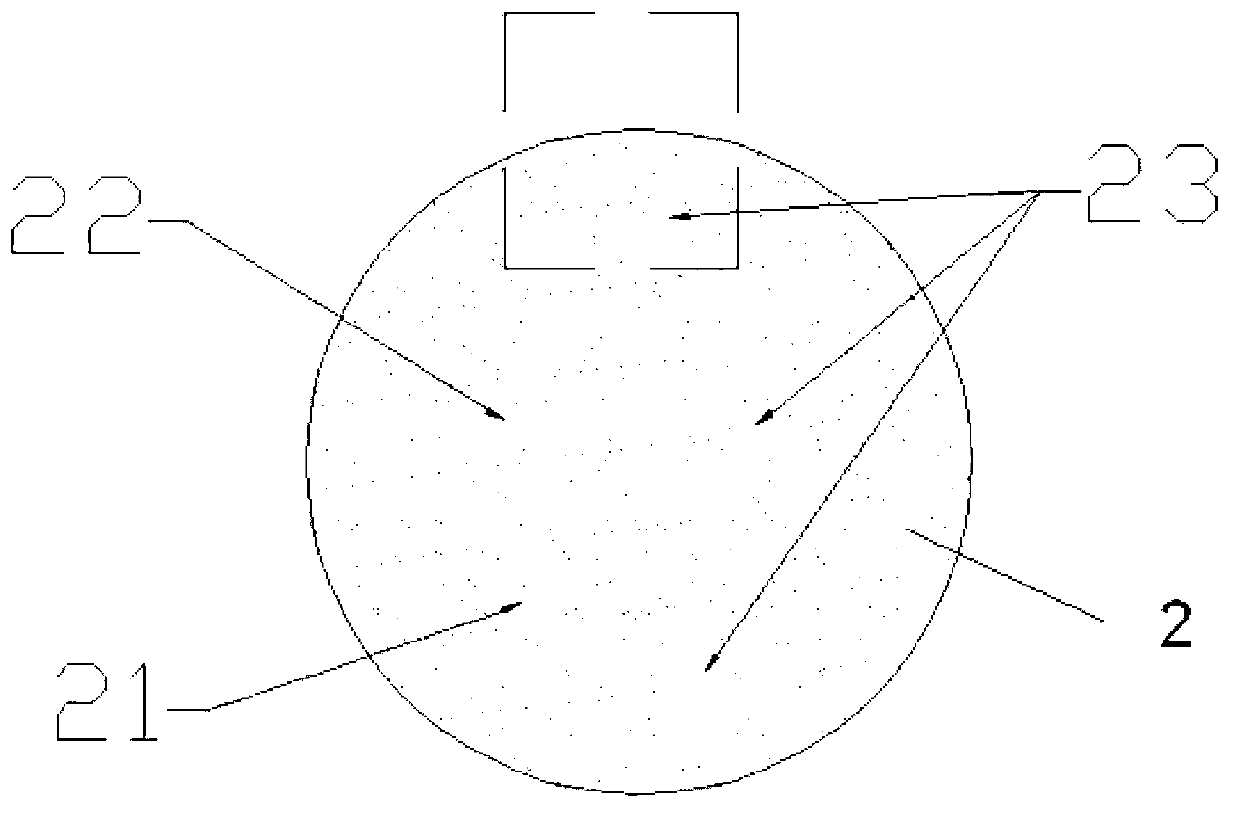

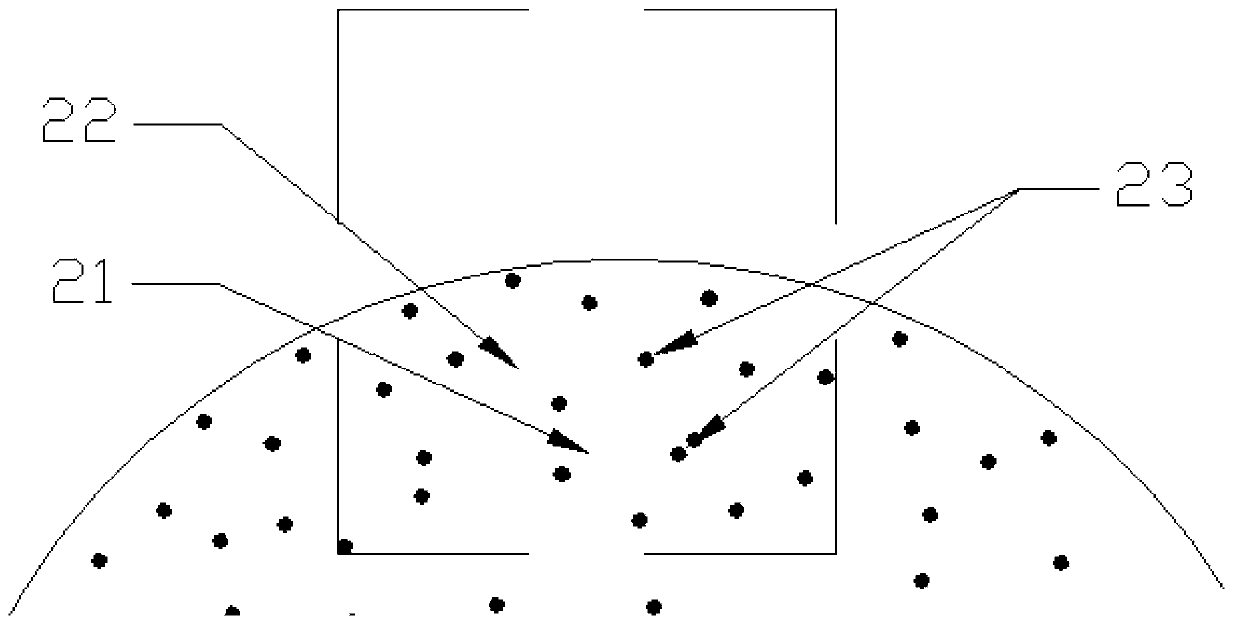

[0052] According to the first embodiment of the present invention, the drug coating formed by the mixture of solid particles can be formed by physical cross-linking of a single solid particle in a wet state. At this time, the "single solid particle" refers to a solid particle with the same form of expression. In this embodiment, the solid particle is a uniformly dispersed particle 2, such as figure 2 shown.

[0053] Usually, the solid particles at least include drug molecules and polymers, and the polymers can be a degradable hydrophilic / water-soluble polymer, or a combination of degradable polymers and hydrophilic / water-soluble polymers. mixture. Wherein, the drug molecules are uniformly dispersed in the polymer. For example in figure 2 and image 3 In , the number 21 indicates the degradable polymer, the number 22 indicates the hydrophilic / water-soluble polymer, and the number 23 indicates the drug molecule.

[0054] The method of forming the microparticles in uniform...

Embodiment 2

[0067] Example 2 Solid particle mixture according to another embodiment of the present invention

[0068] According to the second embodiment of the present invention, the drug coating formed by the mixture of solid particles can be formed by physical cross-linking of a single solid particle in a wet state. At this time, the "single solid particle" refers to a solid particle with the same form of expression. In this embodiment, the solid particle is a particle 3 in the form of a skin-core, such as Figure 7 shown.

[0069] Usually, the solid particles at least include drug molecules and polymers, and the polymers can be a degradable hydrophilic / water-soluble polymer, or a combination of degradable polymers and hydrophilic / water-soluble polymers. mixture. Wherein, the drug molecules are uniformly dispersed in the polymer. For example in Figure 7 In , the number 31 represents a degradable polymer, the number 32 represents a hydrophilic / water-soluble polymer, and the number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com