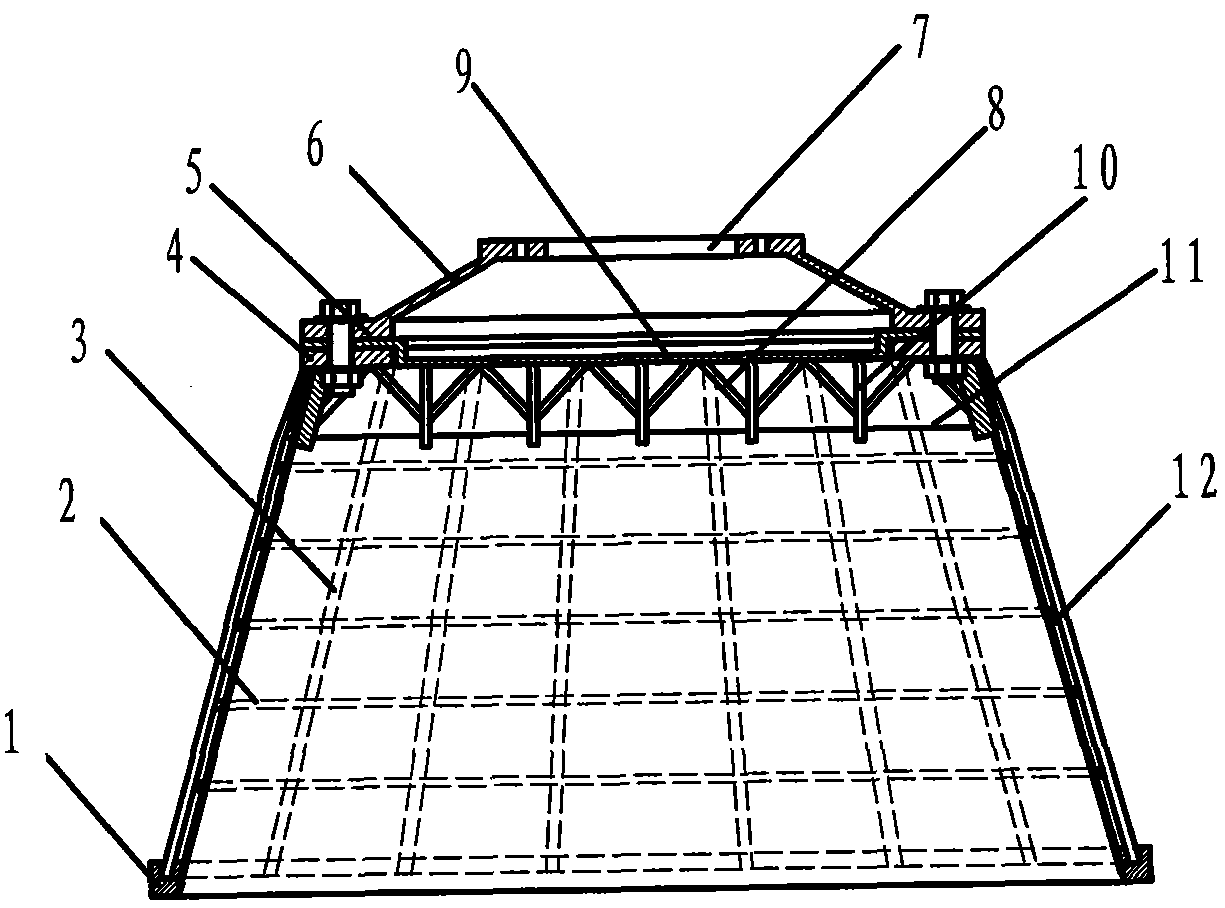

Framework assembly sieve basket of horizontal vibrating centrifuge

A technology of vibrating centrifuge and combination body, applied in directions such as centrifuges, can solve the problems of increasing production cost, affecting filtration efficiency, complicated structure, etc., and achieving the effects of convenient production, improved production efficiency and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] see figure 1 As shown, the present invention provides a screen basket of a skeleton assembly of a horizontal vibrating centrifuge. It can be seen from the schematic diagram that the shape of the technical scheme is a conical skeleton assembly screen basket, and upper flanges 4 and lower flanges are arranged at both ends. Lan 1 is connected with rib bar 3 and screen ring bar 2 to form a skeleton combined screen basket. The upper flange 4 and the lower flange are cut by gas-cutting medium plate steel, and the material is carbon structural steel. Make the mold of the inner diameter body of the sieve basket assembly, place the screen ring bar 2 in the mold for clamping and positioning, arrange the upper flange 4, the lower flange 1 and the ribs 3 in the mold for clamping and positioning, first place the Corner spot welding and then symmetrical welding, the welded sieve ring bar 2 contact points are uniform and then welded firmly, after the welding is completed, the mold is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com