Method for comprehensive stabilization of iron tailings gravel base course through cement and soil stabilizer

A technology of soil curing agent and pavement base, which is applied in the field of fixed buildings and roads in Part E, which can solve the problems of environmental pollution of iron ore tailings and shortage of sand and gravel materials, and achieve the effect of solving the shortage of sand and gravel materials and solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

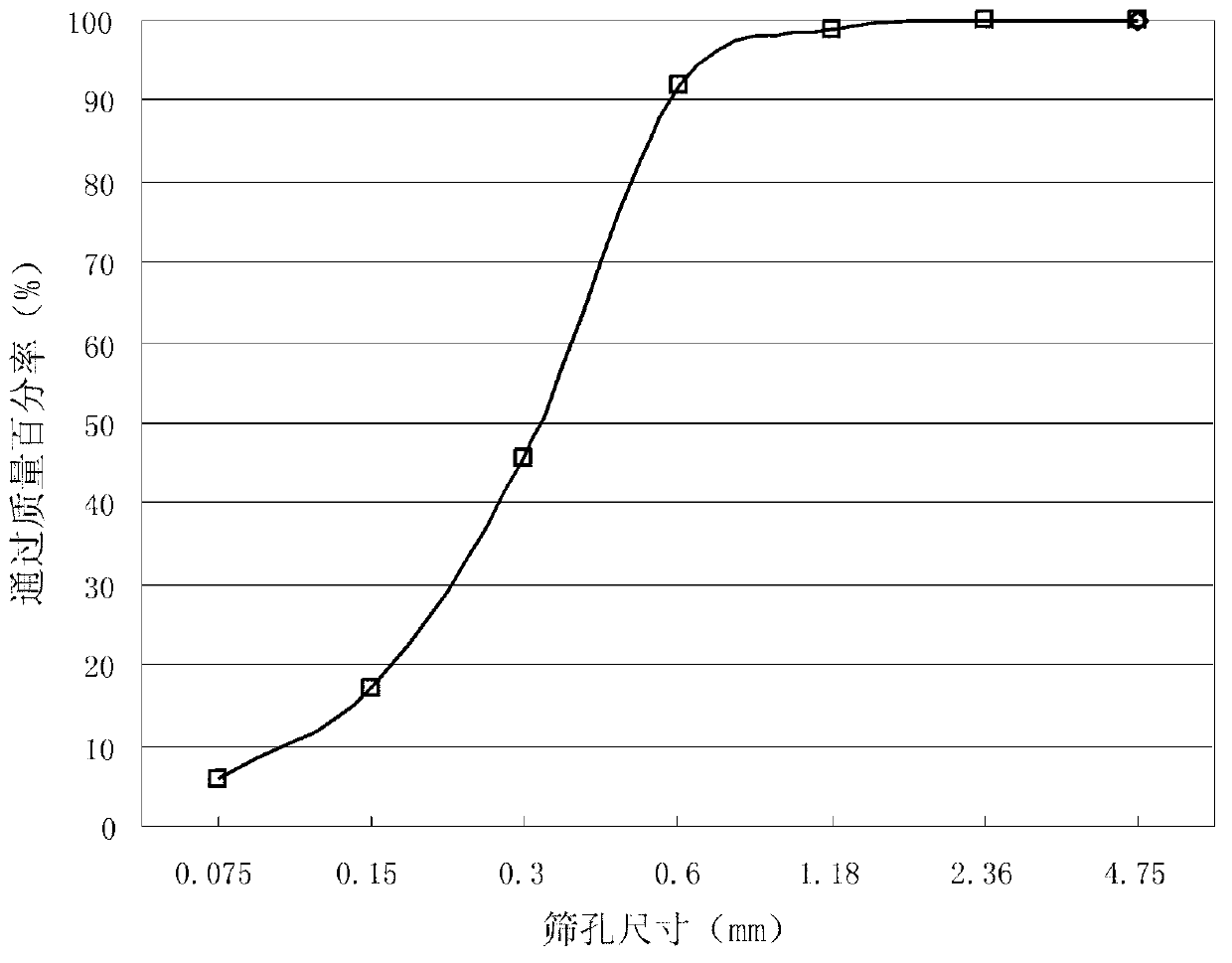

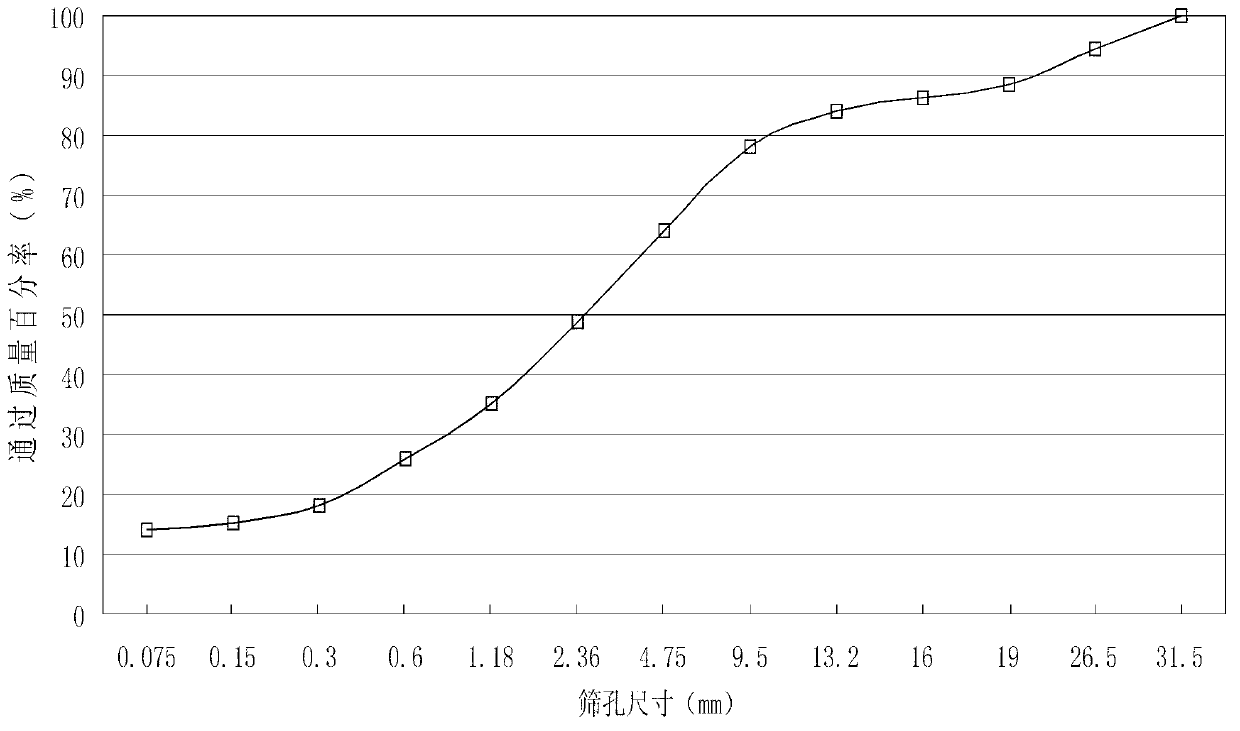

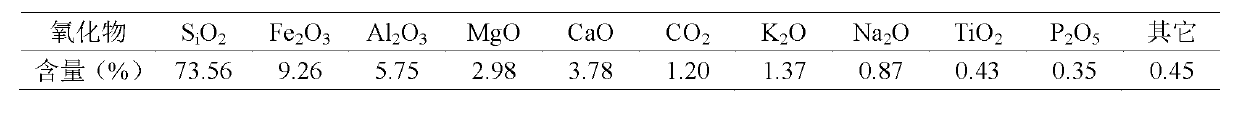

[0009] In this pavement base method, iron tailings sand and gravel are taken from Jianping County, Chaoyang City, Liaoning Province. The cement is 32.5 grade ordinary Portland cement, and the curing agent is ZL-2A type curing agent produced by Jilin Zhonglu New Material Co., Ltd.

[0010] Road-mixing method and concentrated plant-mixing method can be used for pavement base construction, and road-mixing method can be used for secondary roads and lower roads; construction on expressways and first-class roads must be constructed using centralized plant-mixing method. The construction process of the road mixing method is as follows: pave the iron tailings sand and gravel, use the road mixer for initial mixing 2 times, immediately spray the curing agent diluent, and then use the mixing machine to mix 2~3 times after spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com