Method for constructing from central area to periphery of ultra-large type underground engineering

An underground engineering and construction method technology, applied in water conservancy projects, underwater structures, infrastructure engineering, etc., can solve problems such as high cost of support systems, construction progress, difficulty, increased risk, and expensive construction enclosures, etc., to achieve The effect of improving construction safety and reliability, saving project cost, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

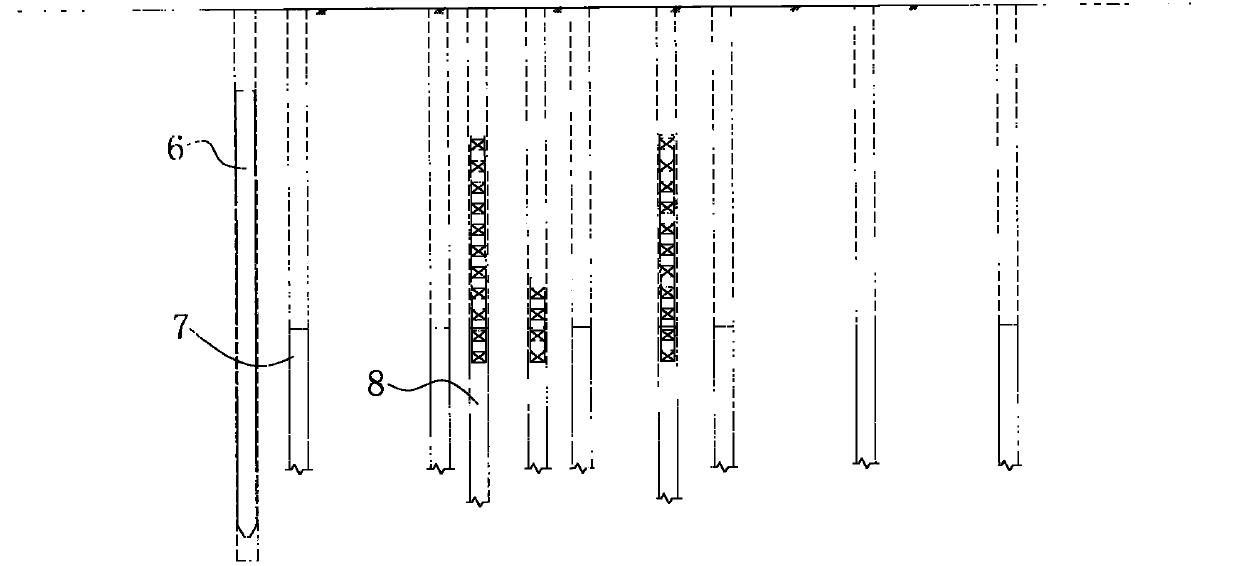

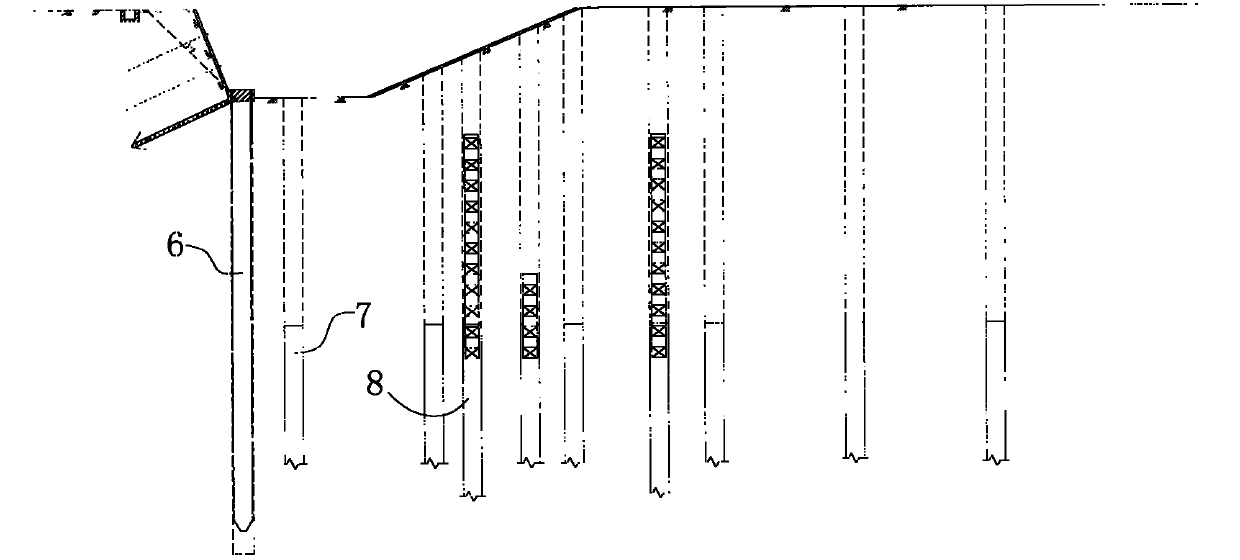

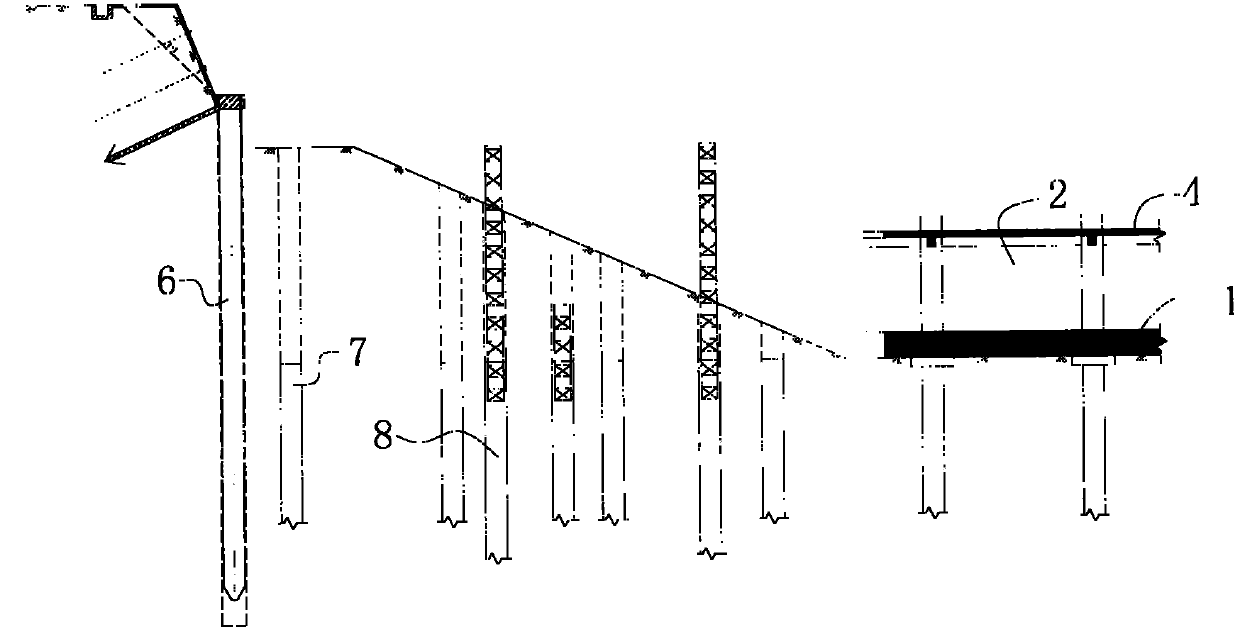

[0036] like Figure 1-9 As shown, a construction method in which the central area of a super-large underground project is combined with the surrounding areas, the specific construction steps are as follows:

[0037] 1), construction foundation pit enclosure wall 6, engineering pile 7, support and trestle support pile 8;

[0038] 2) grading of the upper soil around the foundation pit or excavation of soil nailing wall enclosure, control deformation anchor rods under construction and support conditions, and pouring top beams;

[0039] 3) The central area is sloped and excavated to the bottom, and the basement floor 1 and the third underground floor 2 floor 4 structure of the central area are completed;

[0040] 4) Combining the surrounding conditions, the upward construction completes the structure of the second floor 3 underground in the central area, and at the same time, the beam slab 5 or beam structure of the second underground floor in the surrounding area is completed i...

Embodiment 2

[0053] like Figure 10-18 As shown, a construction method in which the central area of a super-large underground project is first combined with the surrounding area, the surrounding support system is a temporary surrounding support 11 supported by reinforced concrete or steel, and the specific construction steps are as follows:

[0054] 2.1), according to step 1, 2, 3 construction in embodiment 1, in the step 4, construct the second-floor 3 slab structure underground in the central region, and construct the fence beam and peripheral support 11 simultaneously, so that the peripheral support 11 is connected with 4 underground second-floor slabs As a whole, the setting height of the peripheral support 11 should enable the excavator and the earth truck to drive normally to carry out the excavation operation; then carry out the construction according to steps 5 and 6;

[0055] 2.2), remove trestle bridge 9 in step 7, and construct the basement floor 1 in the surrounding area and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com