High-pressure load bearing wallboard and preparation method thereof

A wall panel and load-bearing technology, which is applied in the field of high-pressure load-bearing wall panels and their preparation, and building envelope structures, and can solve problems such as difficult construction, difficult construction, and poor fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

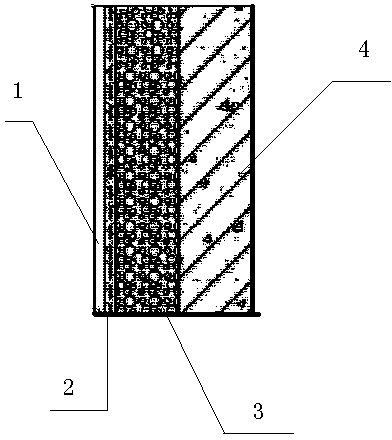

[0010] Such as figure 1 As shown, a high-pressure load-bearing wall panel consists of a concrete structure layer 4 , an insulation layer 3 , a protective layer 2 , and a decorative layer 1 in a prefabricated manner from inside to outside.

[0011] In this embodiment, the wall panels are arranged on the outer layer of the building foundation structure, and the wall panels and the foundation structure, and the wall panels are connected by preset fixing parts. In this embodiment, the decorative layer 1 is made of finishing mortar. In this embodiment, the protective layer 2 is composed of polymer modified cement mortar and alkali-resistant grid cloth. In this embodiment, the thermal conductivity of the inorganic thermal insulation mortar used for the thermal insulation layer 3 is 0.085W / m.K, and the compressive strength after it is manufactured is greater than 1.OMPa. ] In this embodiment, the concrete structure layer 3 is made of prefabricated reinforced concrete. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com