Environment-friendly and energy-saving hollow glass

An environmentally friendly, energy-saving, hollow technology, applied in parallel glass structures, using liquid/vacuum for liquid tightness measurement, and detecting the appearance of fluid at leak points, etc., can solve problems such as unfavorable energy saving, environmental protection, and unsatisfactory heat insulation performance , to achieve the effect of reducing heating costs and energy, good lighting effects, and reducing air-conditioning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

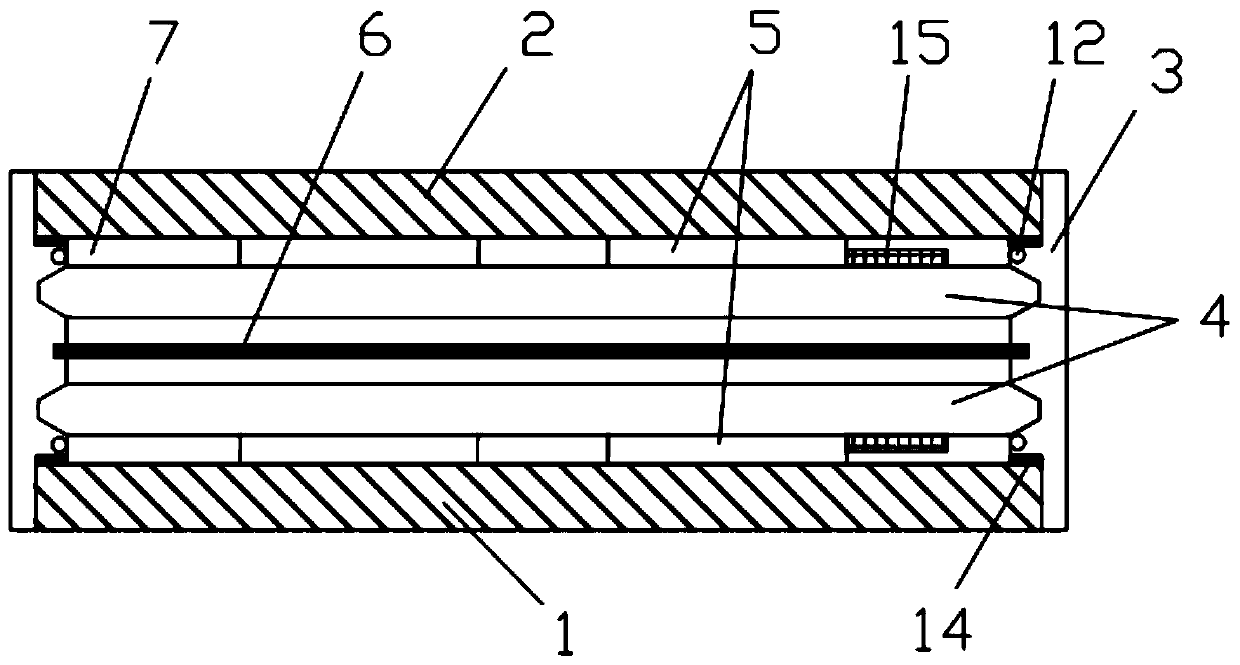

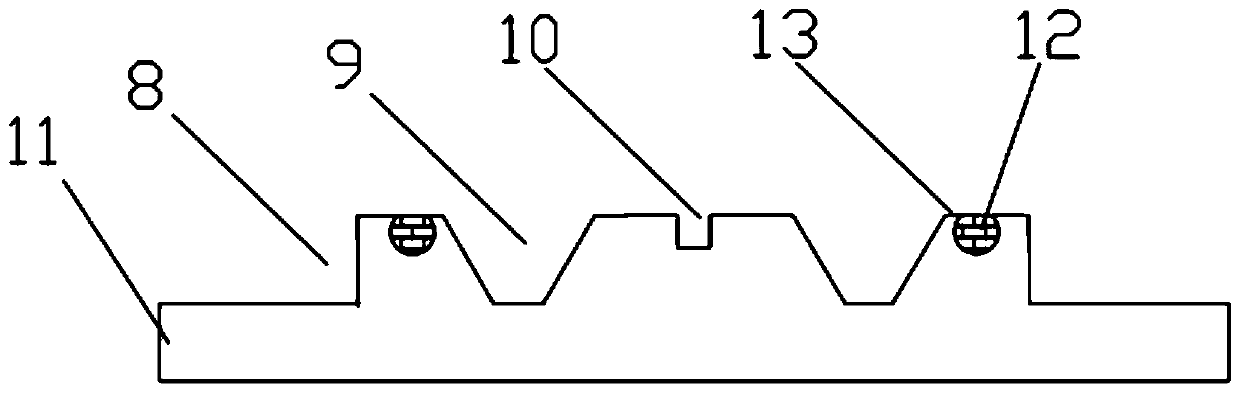

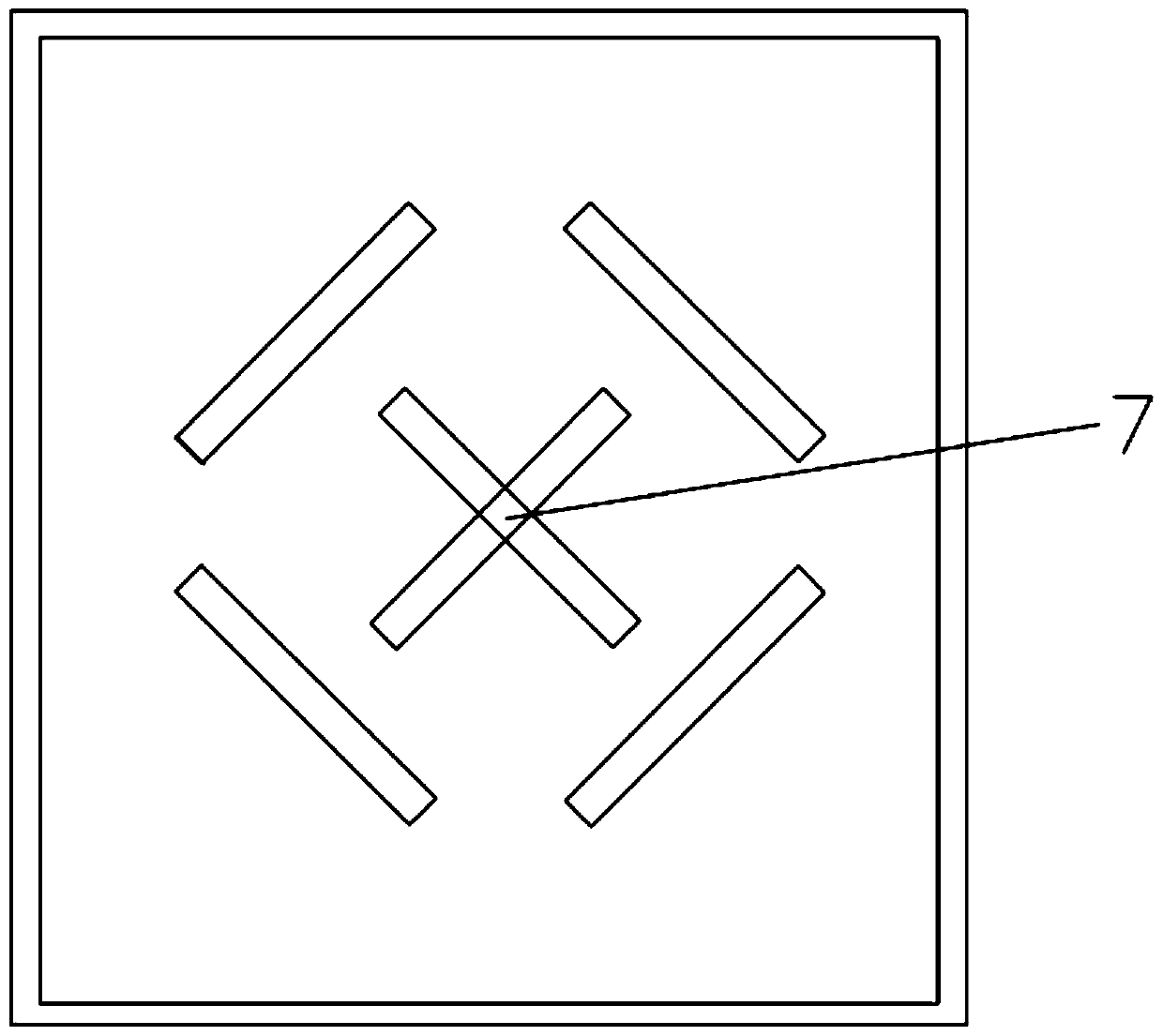

[0021] Embodiment one: Figure 1-Figure 3It shows an environment-friendly and energy-saving insulating glass, which includes an outer glass layer 1, an inner glass layer 2 and a sealing frame 3, and two transparent plastic layers 4 are arranged between the outer glass layer 1 and the inner glass layer 2, so that The two sides of the transparent plastic layer are respectively provided with a zinc oxide layer and a titanium dioxide layer, and a cavity 5 is formed between the two transparent plastic layers 4 and between the outer glass layer 1 and the inner glass layer 2; between the two transparent plastic layers 4 A low-emissivity film 6 is arranged in the cavity, and the transparent plastic layer with a coating has good light transmittance and also has a good heat insulation function, so that the sound insulation and heat insulation effect of the present invention is better, and the glass as a whole It can also play a certain supporting role, and form a cavity part, and evacua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com