Waste heat discharge pump shaft cooling structure

A technology of waste heat discharge pump and cooling structure, applied in the field of centrifugal pump, can solve the problems of slow water flow, poor heat exchange effect, unsatisfactory cooling effect, etc., to achieve the effect of simple structure and enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

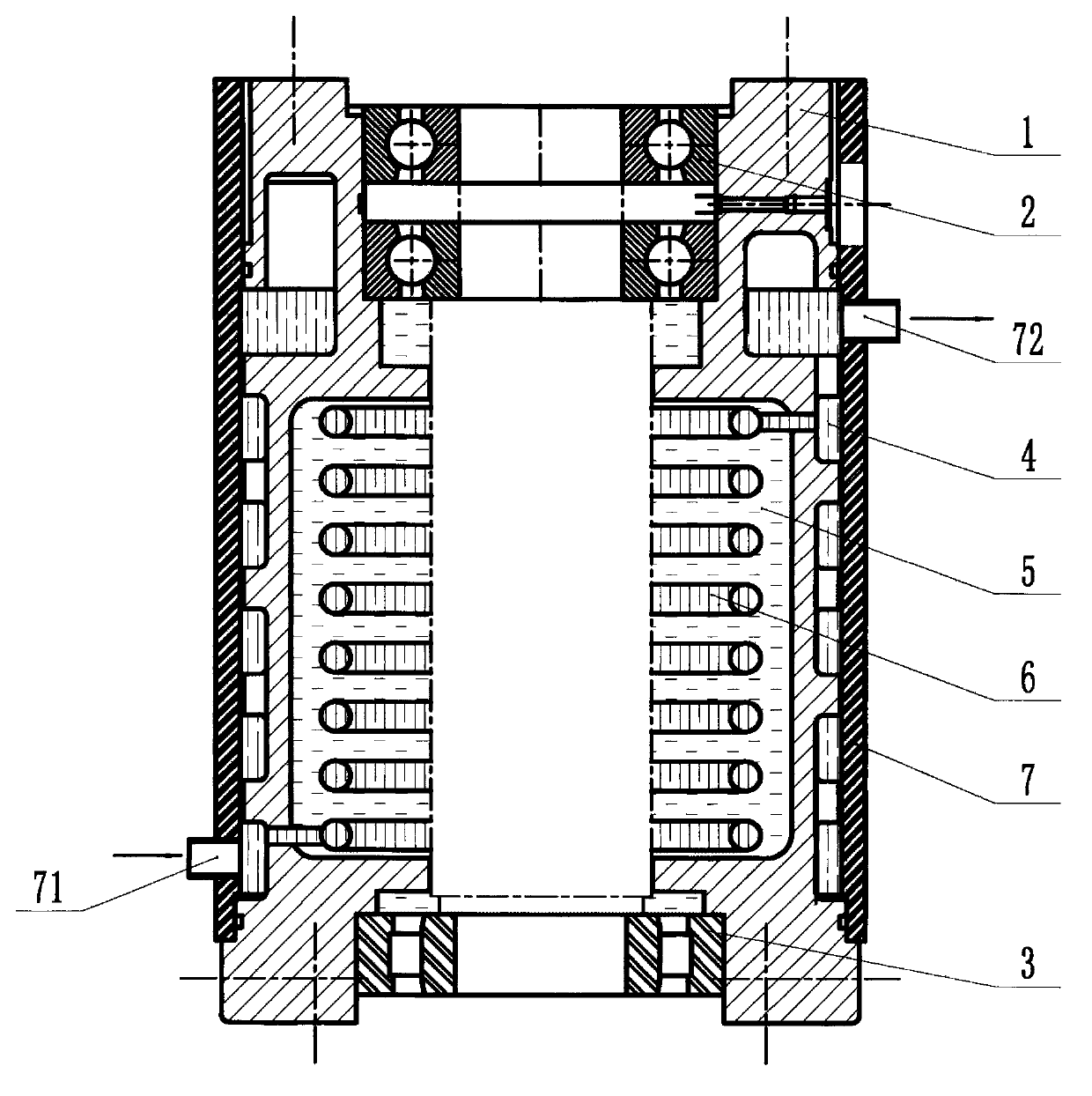

[0013] In conjunction with the accompanying drawings, the waste heat discharge pump shaft cooling device of the present invention includes a bearing housing 1, a deep groove ball bearing 2, a cylindrical roller bearing 3, cooling water 4, lubricating oil 5, cooling water pipeline 6, cooling water jacket 7, Components such as the water inlet 71 and the water outlet 72, the cooling water pipeline 6 are installed on the bearing housing 1, and are used to cool the pump shaft together with the spiral outer flow channel, so as to achieve the effect of safe shutdown of the nuclear island.

[0014] The working process is as follows:

[0015] The cooling water 4 enters the bearing box 1 through the water inlet 71 and is divided into two paths, one path passes through the flow channel in the external cooling water jacket 7; the other path passes through the spiral cooling water path 6 of the cooling chamber of the bearing box 1. The external flow channel in the cooling water jacket 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com