Method and system for avoiding slagging of circulating fluid bed boiler furnace

A circulating fluidized bed and boiler furnace technology, applied in the field of boiler combustion, can solve problems such as slagging accidents, poor furnace temperature control, etc., achieve the best technical effect and avoid the effect of furnace slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

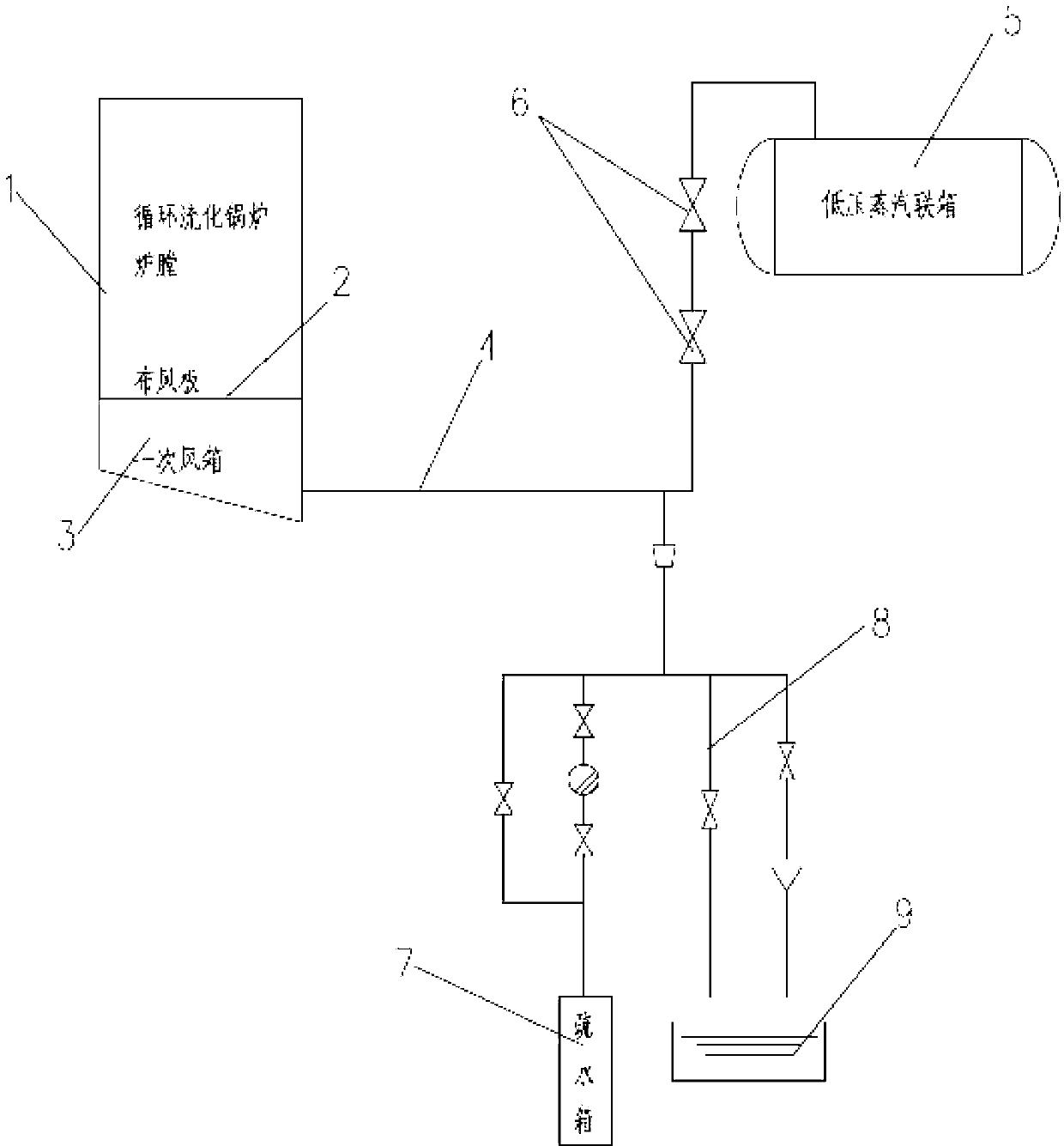

[0012] A method for avoiding slagging in the hearth of a circulating fluidized bed boiler in this embodiment, when applied to the hearth of a circulating fluidized bed boiler, the low-pressure saturated steam is sequentially squeezed through the wind box and the air distribution plate and introduced into the hearth of the circulating fluidized bed boiler in combustion , can temporarily block its combustion, and can avoid slagging in the furnace of the circulating fluidized bed boiler. This method can manually introduce low-pressure saturated steam at any time according to needs. Of course, low-pressure saturated steam can also be introduced into the furnace at regular intervals to maintain the effect of continuously avoiding slagging. This embodiment is easy to operate and low in labor intensity. Exemplarily, the preferred pressure of the low-pressure saturated steam in this method is 0.5 MPa, and the corresponding temperature of the low-pressure saturated steam can be directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com