Aluminum ingot melting furnace graphite plate connection rod

A melting furnace and graphite plate technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of delayed production, time-consuming replacement of graphite rods, and scrapping, etc., to achieve the effect of improving service life and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

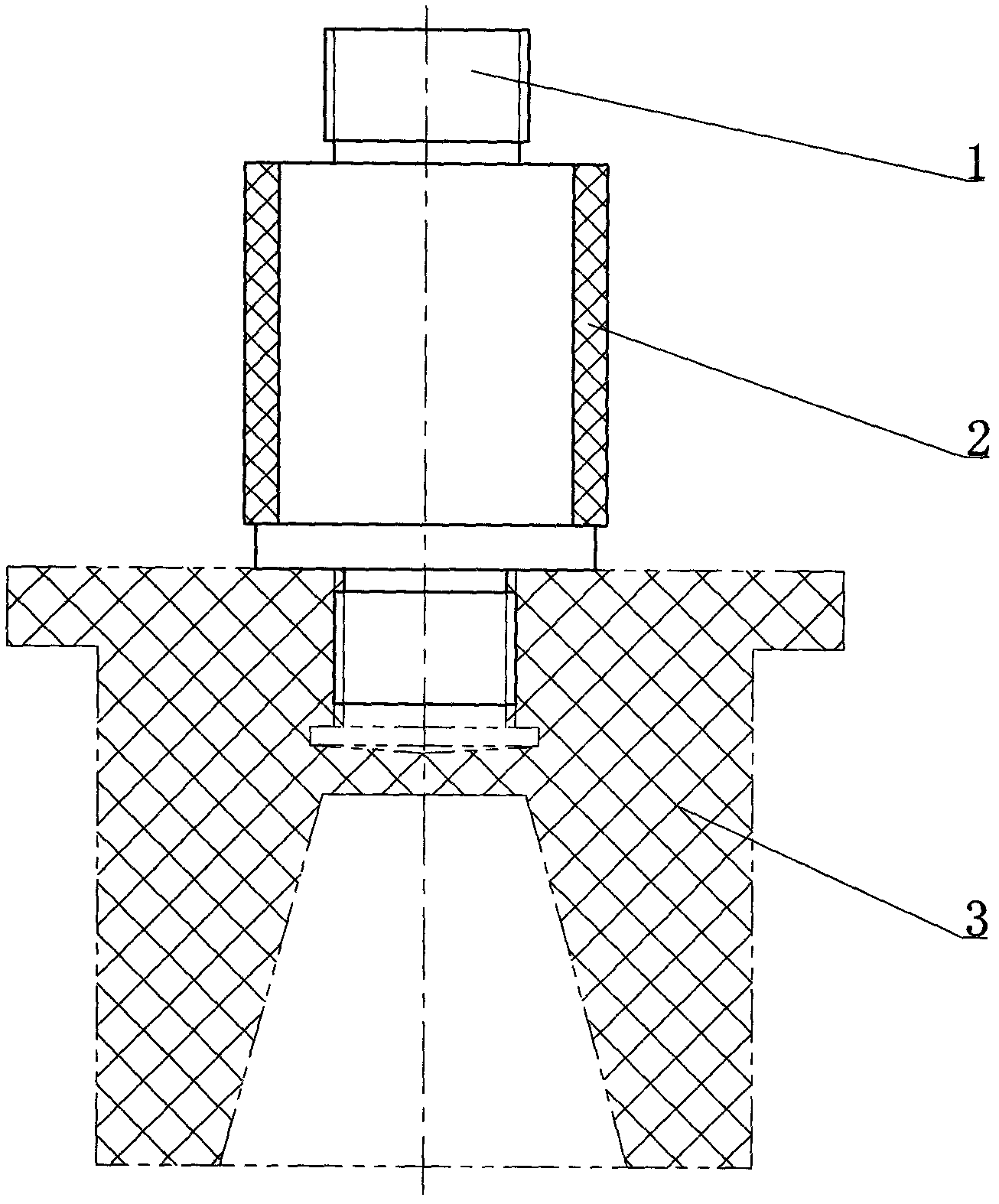

[0007] figure 1 Shown in is a specific embodiment of the present invention. The connecting rod of the graphite disc of the aluminum ingot melting furnace of the present invention includes a shaft 1, and a protective sleeve 2 is installed on the outer surface of the shaft 1. A clearance fit is adopted between the inner hole of the protective sleeve 2 and the outer circle of the shaft 1 . Shaft 1 is a stepped shaft with an external thread at both ends, and the material used is No. 45 steel. The protective cover 2 has a circular tubular structure, and the material used is silicon carbide.

[0008] When in use, the lower end of the shaft 1 is connected to the graphite disc 3 through threads, and the upper end of the shaft 1 is connected to the autorotation machine through threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com