Radial corrugated pipe diaphragm-freezing-preventive pressure gauge with fluorescent indications on dial scales

A pressure gauge and bellows technology, which is used in elastic deformation gauge-type fluid pressure measurement, fluid pressure measurement, and measurement devices, etc. pressure capacity and other issues to achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further describe the present invention, specific examples of implementation are illustrated below in conjunction with the accompanying drawings.

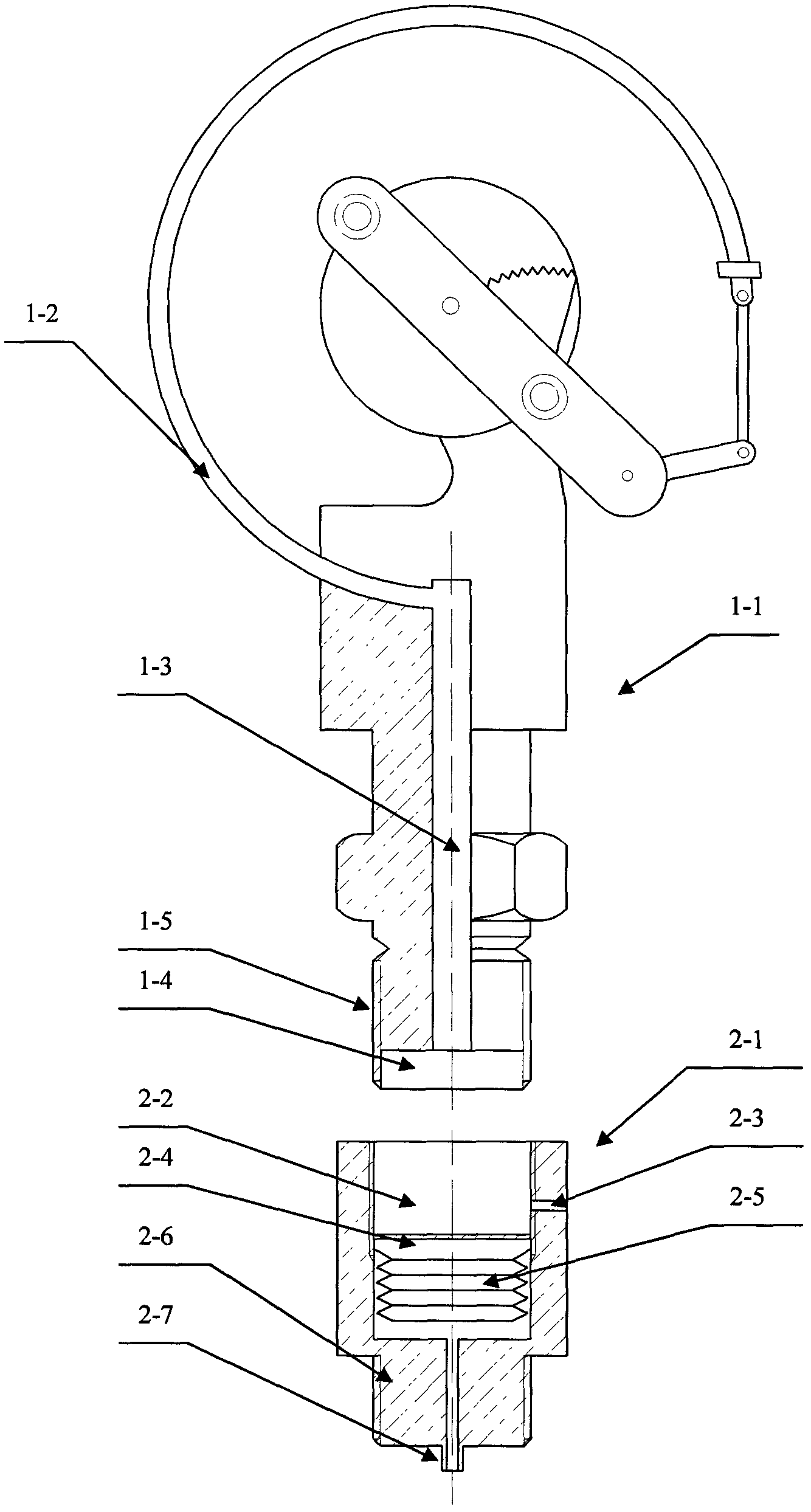

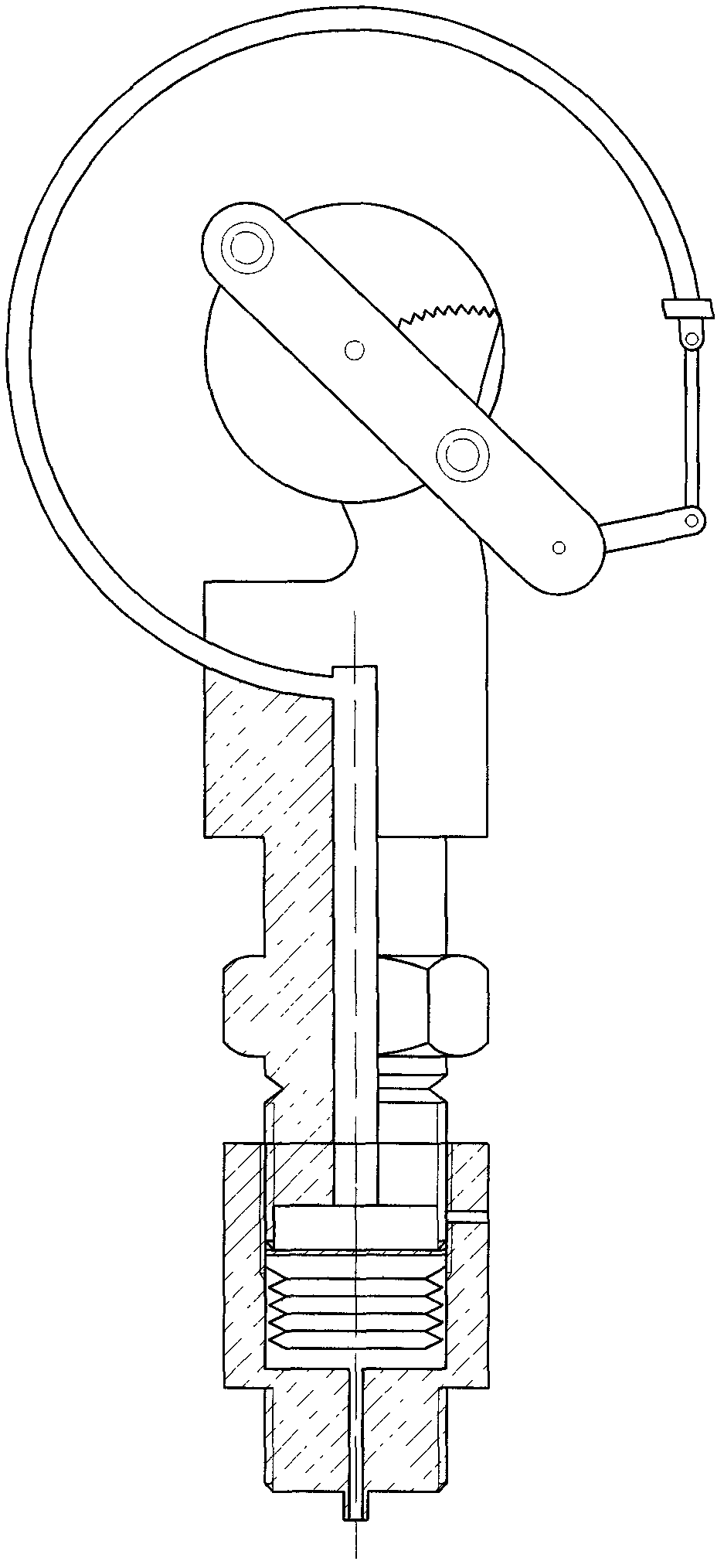

[0020] First install the bellows 2-5 on the lower part of the concave opening 2-2 on the sensing diaphragm of the pressure gauge. The bellows 2-5 is filled with antifreeze, and the bellows 2-5 is installed with a pressure sensor with pressure transmission capability. The diaphragm 2-4 is provided with a process hole 2-3 on the side of the pressure gauge sensing diaphragm part 2-1. When the lower joint 1-5 of the pressure gauge indication part is screwed into the upper recessed opening 2-2 of the pressure gauge sensing diaphragm part, the pressure sensing diaphragm 2-4 is clamped between the lower joint 1-5 of the pressure gauge indication part and the pressure gauge Between the recessed opening 2-2 on the sensing diaphragm part. While screwing in part of the lower joint 1-5 of the indication part of the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com