Method for coating diffusion film coating

A diffusion film and diffusion layer technology, which is applied in the direction of optical components, instruments, optics, etc., can solve the problems of no coating process and processing methods, and achieve the effect of improving the diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

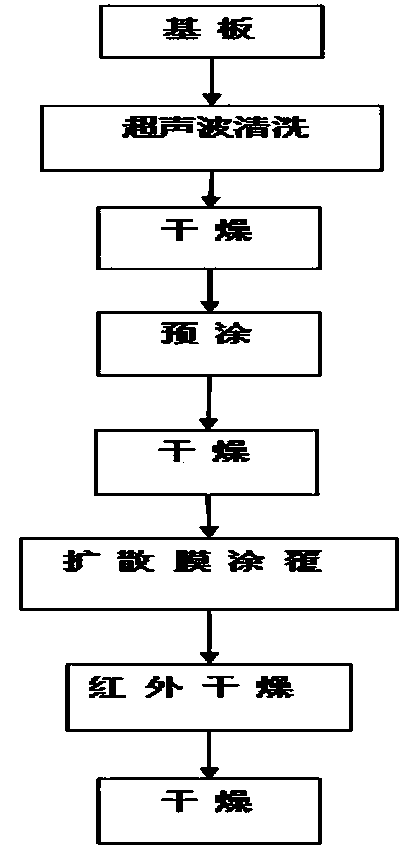

[0021] Taking the coating of a diffusion film on the light guide plate substrate as an example, the method flow chart of this method is as follows figure 1 As shown, the specific steps are: the first step, ultrasonic cleaning, the TFT-LCD glass substrate to be cleaned is sent to the ultrasonic cleaning device through the input conveyor, the ultrasonic frequency is controlled at 28KHz-40KHz, the handling speed is 3m / min, pure The water flow rate is 30L / min. At this time, the cleaning effect is the best, and then dry it with a drying oven at about 60°C. In the second step, pre-coating, a scratch-resistant layer composed of a scratch-resistant material is coated on the glass substrate, and the coating is carried out by gravure printing. The thickness of the scratch-resistant layer is controlled between 1um-2um. The third step is drying. After the pre-coating is completed, use a drying oven to dry at 55-70°C. The fourth step is to coat the diffusion film. First, prepare the coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com