Thin-film capacitor structure for direct-current link circuits

A film capacitor and line technology, applied in the structural field of DC link line film capacitors, can solve problems such as complex and harsh environments, achieve good stability, good overcurrent and self-healing ability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

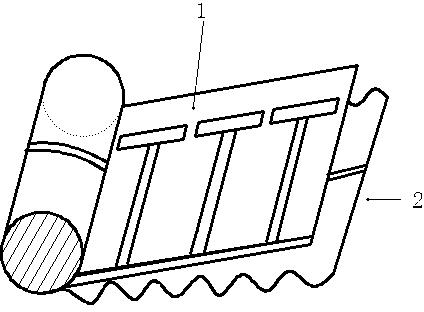

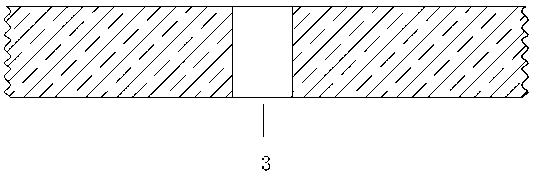

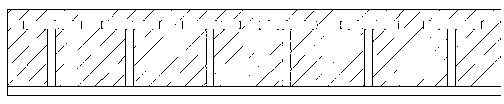

[0016] Such as figure 1 , 2 , Shown in 3: a kind of structure that is used for DC link line film capacitor, comprises bottom layer 1 and outer layer 2, and described bottom layer 1 is metallized T-type safety film with double side left, and described outer layer 2 is double side left side The width of the light film 3 at the edge of the double-sided metallized film is 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com