Low-caffeine broken black tea

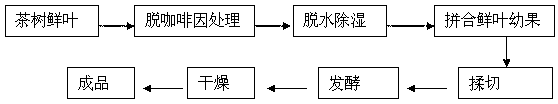

A low-caffeine, red crushed tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of food quality and safety hazards, expensive processing equipment, high processing costs, etc., so that the tea soup is not turbid, the soup is red and bright, and has a broad market prospect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Picking of fresh leaves: pick the fresh leaves of tea tree varieties suitable for black tea with one bud and three leaves as raw materials; at the same time, pick and collect young tea tree fruits and tender stems. Adopt two kinds of treatment A, B (control), A enters step (2), B enters step (5) directly.

[0016] (2) Decaffeination treatment of fresh leaves: decaffeination of fresh tea leaves by immersion and rinsing method with gradient cooling in hot water, that is, the fresh leaves of tea trees are evenly mixed with hot water in a certain proportion (tea water ratio 1:15), combined with heating, so that the leaves after mixing Keep the temperature at 95°C for 30 seconds, then quickly immerse the tea leaves in an appropriate amount of warm water at 60°C, keep for 30 minutes, then remove the fresh leaves and rinse with cold water to complete the decaffeination step.

[0017] (3) Dehydration and dehumidification: The decaffeinated fresh leaves are filtered through ...

Embodiment 2

[0027] (1) Picking of fresh leaves: picking fresh leaves of tea tree varieties suitable for black tea with one bud and two leaves as raw materials; using two treatments C and D (control), C enters step (2), and D directly enters step (5).

[0028] (2) Decaffeination treatment of fresh leaves: decaffeination with hot water gradient cooling dipping and rinsing method, that is, the fresh leaves of tea trees are evenly mixed with hot water at a ratio of 1:10, combined with heating, so that the temperature of the leaf water after mixing is 85°C, Keep it for 300 seconds, then quickly immerse the tea leaves in loose warm water at 50°C, keep it for 15 minutes, take out the fresh leaves and shower with cold water to complete the decaffeination step.

[0029] (3) Dehydration and dehumidification: The decaffeinated fresh leaves are filtered through a vibrating tank and dehydrated by a centrifuge to remove water on the surface of the buds and leaves. The centrifuge rotates at 1000 rpm and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com