Equipment and tail gas treatment method for synchronously treating tail gas of multiple graphitization furnaces

A graphitization furnace and simultaneous processing technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems affecting production efficiency, waste of process gas, and energy waste, so as to improve the gas supply process and save construction costs , the effect of reducing the number of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

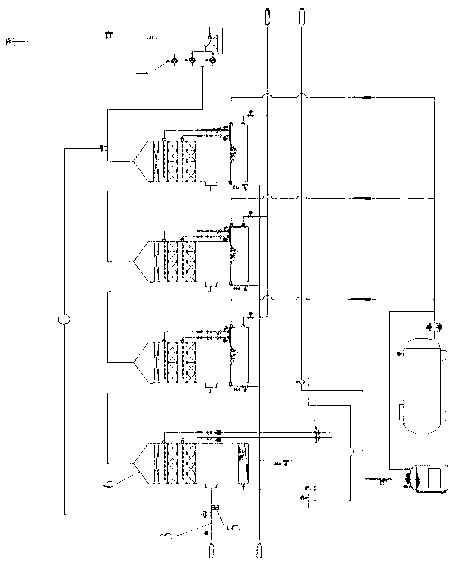

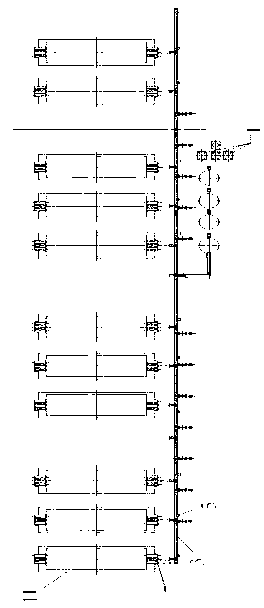

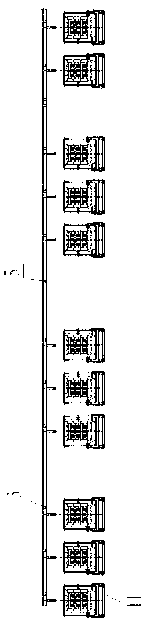

[0038] like Figure 1~Figure 4 As shown, a device for simultaneously processing exhaust gas from multiple graphitization furnaces includes an induced draft fan 1 for controlling the wind pressure and air volume of the exhaust gas main pipe 3 of the graphitization furnace. Absorption system, monitoring system, control system. Among them, the fresh air system is arranged in the furnace cover 2 and the tail gas main pipe 3 of the external graphitization furnace 11; the input end of the turbulence absorption system is connected with the tail gas main pipe 3 of the graphitization furnace through a pipe, and its output end is connected with the external exhaust device through a pipe The monitoring system is set in the fresh air system and the turbulence absorption system; the control system is respectively connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com