Yarn cylinder group type dust collection device capable of effectively preventing dust from returning

A technology of vacuuming device and yarn bobbin, which is applied in the direction of removing smoke and dust, separation method, cleaning method and utensils, etc., can solve the problems of not being able to avoid dust returning, having potential safety hazards, and being difficult to clean thoroughly, etc. Good effect, simplified structure, closed working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

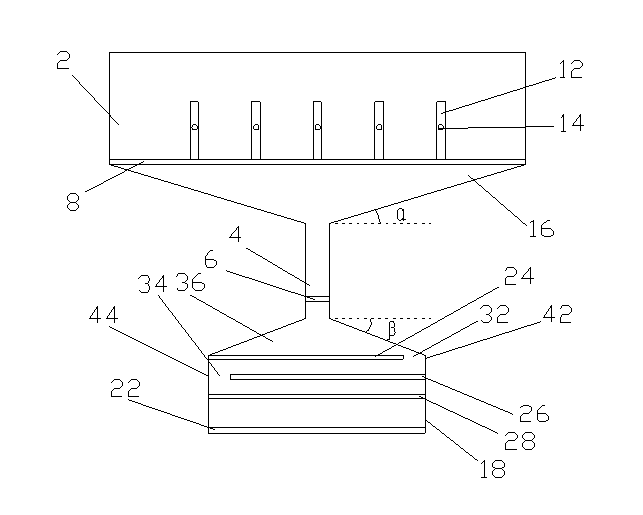

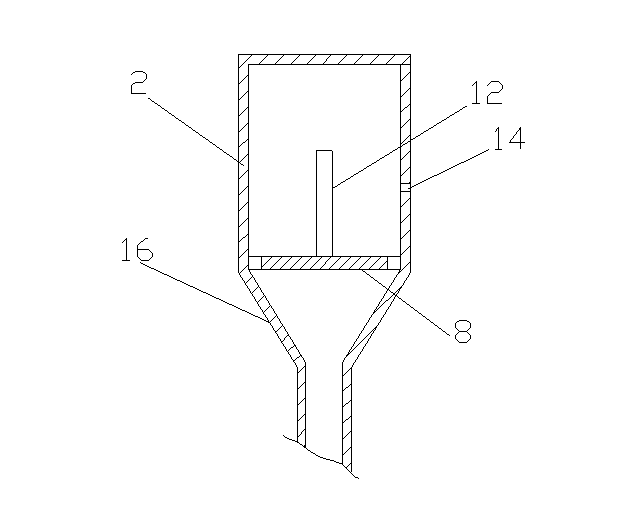

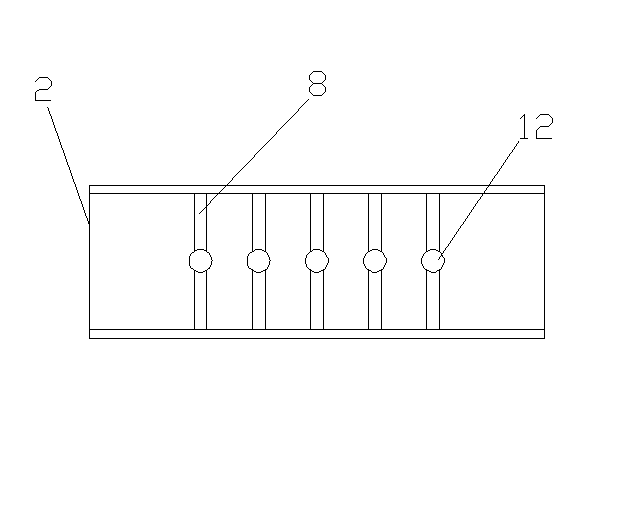

[0014] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0015] Such as Figure 1-3 As shown, a yarn bobbin group dust collection device that effectively prevents dust from returning includes a strip-shaped dust collection cover 2, a dust filter structure that communicates with the dust collection cover 2 through a dust collection pipe 4, and is located in the dust collection pipe 4. The suction fan 6. The inside of the dust collection cover 2 is provided with a yarn bobbin support 8 and five yarn bobbin vertical shafts 12, and the side wall of the dust collection cover 2 has a yarn outlet hole 14. The diameter of yarn outlet hole 14 is 1-3 millimeter. The dust collecting hood 2 includes a rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com