Movable turner for welding circular seam of pipeline

A technology of circular seam welding and pipeline, which is applied in the field of pipeline circular seam welding movable tires, which can solve the problems of unstable placement of fixed tires, affected welding quality, and irregular rotation, so as to avoid all-round welding and improve welding efficiency , The effect of welding quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

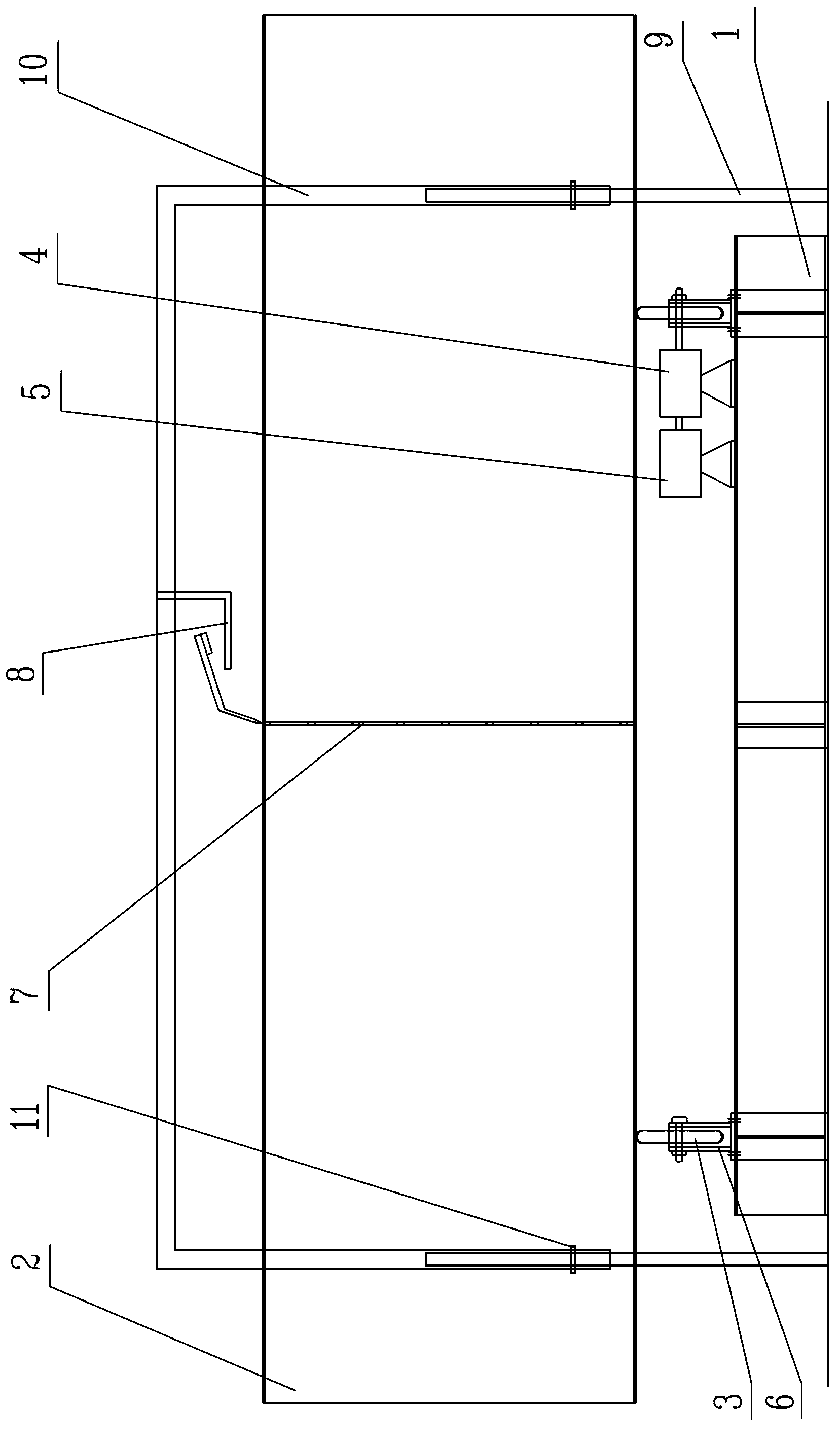

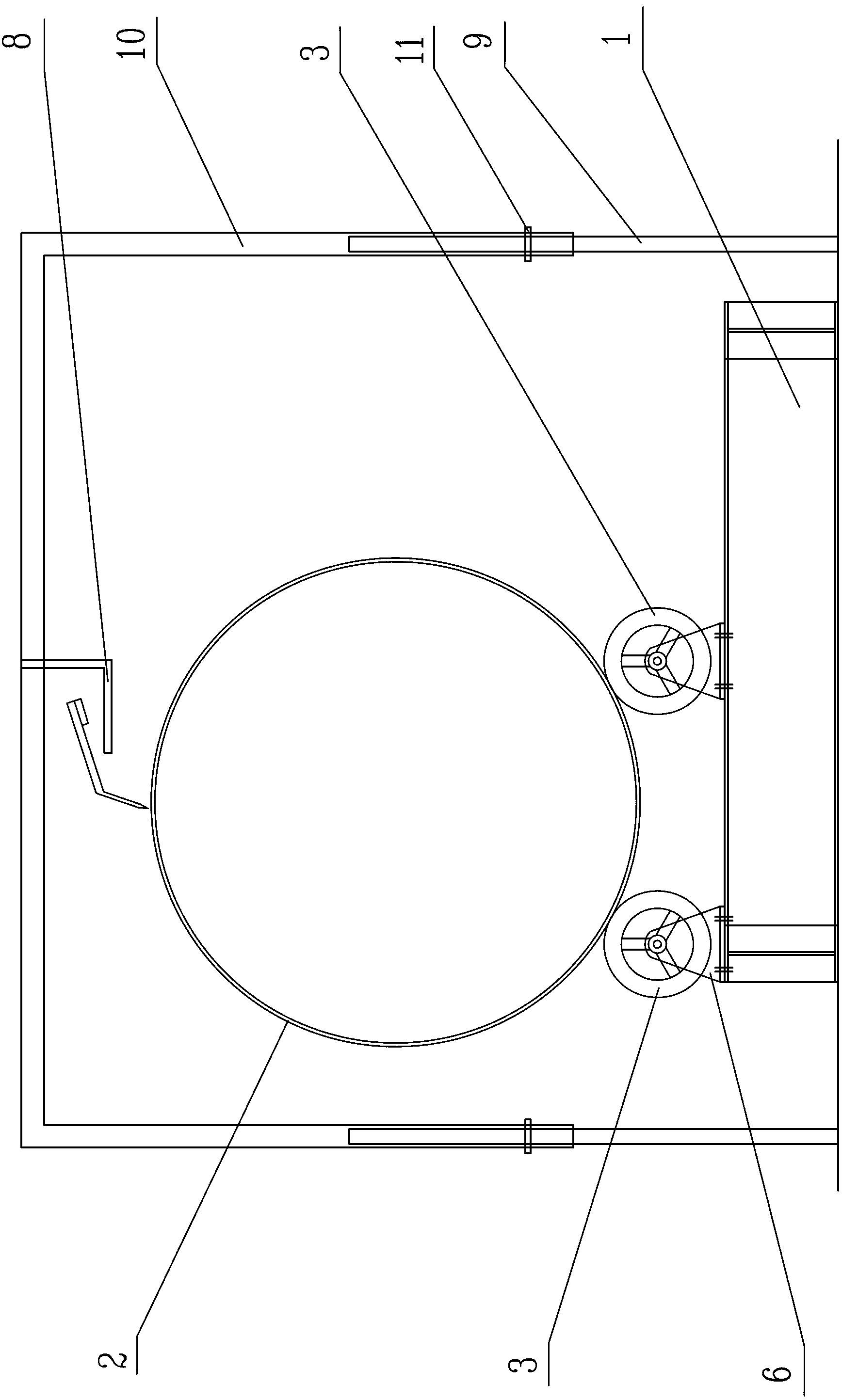

[0018] Now in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0019] The pipe circular seam welding movable tire of the present invention is mainly composed of a base 1, two rows of runners 3 and a frame support.

[0020] The two rows of runners 3 are fastened on the base 1 with bolts through the wheel frame 6. Since the row spacing of the two rows of runners 3 needs to be adjusted, the wheel frames 6 of a row of runners 3 are tightened on the base with bolts. 1 for a fixed position (eg figure 2 The left row of runners 3), the other row of runners 3 (such as figure 2 The right row of runners 3) is tightened on the position of the adjustable distance of the base 1 with bolts. The usual practice is to correspond to a row of runners 3 that are movable. There are multiple sets of screw holes on the base 1. The bolts on the wheel frame 6 at different positions are matched and installed; the power of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com