Processing method of machine tool movable support beam axis, its products and special fixture

A technology of mobile support and special fixture, which is applied in the direction of manufacturing tools, metal processing equipment, abrasive jet machine tools, etc., can solve the problems of high processing cost and inability to guarantee accuracy, and achieve the effect of reducing processing cost, shortening the processing period, and avoiding the need

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

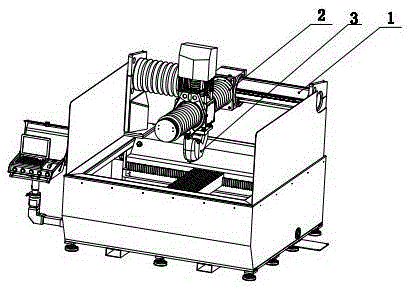

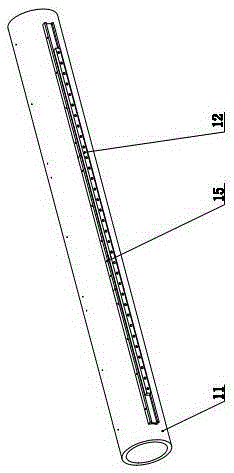

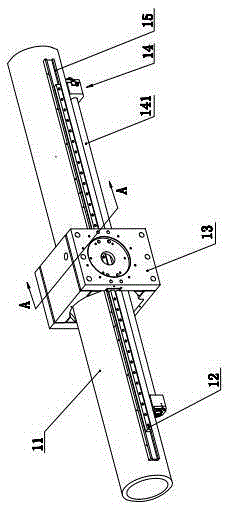

[0039] Such as Figure 1-5 As shown, the embodiment of the present invention is aimed at the application embodiment of the screw drive provided with the guide rail 12 on the beam shaft 11, wherein the groove supporting the guide rail 12 on the beam shaft 11 is constructed by a channel steel 15, and is provided with The screw mandrel 141 of the screw drive assembly 14 is parallel to the guide rail 12, that is, the screw drive assembly 14 is fixed on the beam shaft 11 and the screw mandrel 141 is below the beam shaft 11, and the screw mandrel 141 and the guide rail 12 are all parallel to the horizontal line. The channel steel 15 supporting the guide rail is fixedly connected to the side of the beam shaft 11, and the guide rail 12 is fixed at the placement cavity protruding from the channel steel 15. 131. Both sides of beam shaft 11 are evenly distributed with channel steel 15 ie its groove, beam shaft 11 adopts hollow steel pipe, screw motor 142 of screw drive assembly 14 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com