Water oil storage device with mooring function and assembly method thereof

An oil storage device and mooring technology, used in packaging, transportation and packaging, containers, etc., can solve the problems of large amount of structural materials, large changes in water displacement, non-recyclability, etc., to overcome the influence of free liquid surface and draft changes. Small amount and the effect of reducing the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

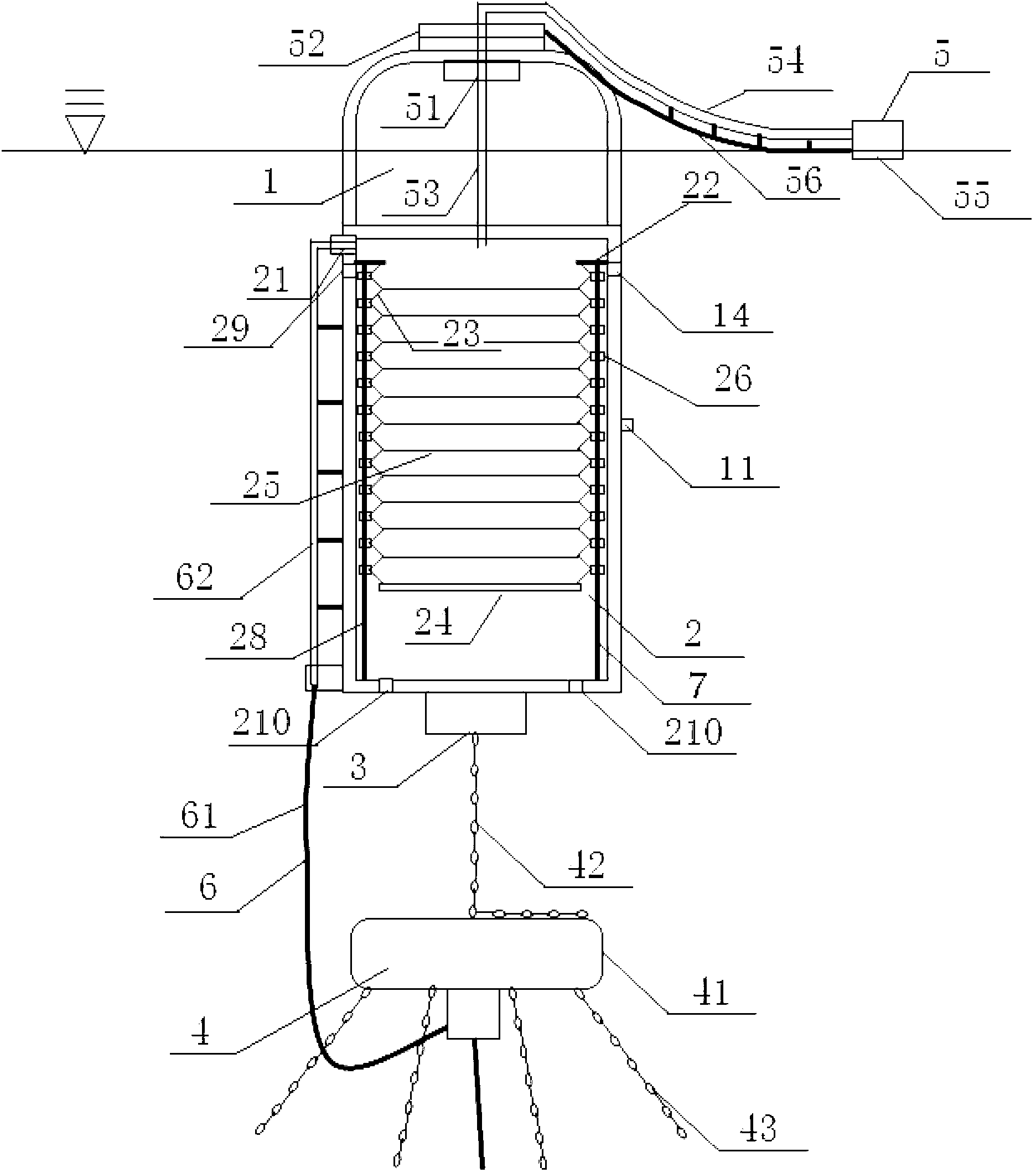

[0021] like figure 1 As shown, the device of the present invention includes an oil storage tank, and the oil storage tank includes one or more buoyancy tanks 1, an oil storage tank 2 and a ballast tank 3; the device of the present invention also includes a set of mooring systems 4, a set of Outward transmission system 5 and a set of oil delivery system 6.

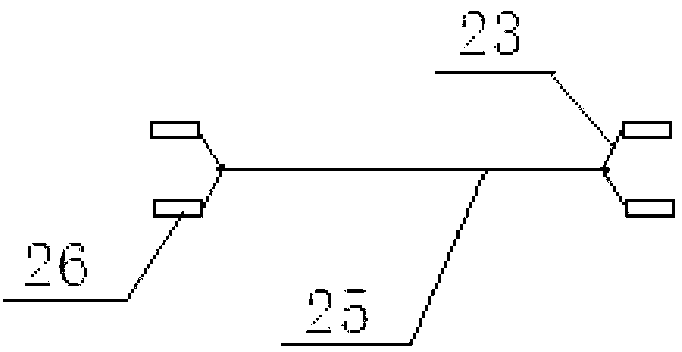

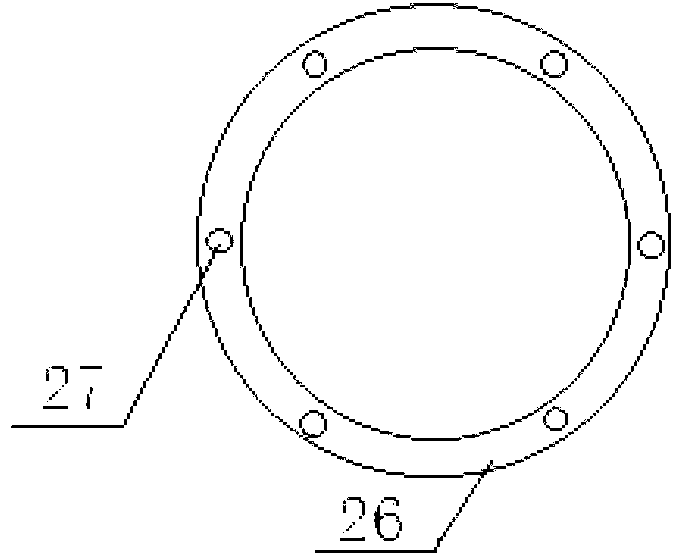

[0022] like figure 1 As shown, buoyancy cabin 1, oil storage tank 2 and ballast tank 3 of the present invention are all cylindrical structures, and the outer diameter and inner diameter of buoyancy cabin 1 correspond to the outer diameter and inner diameter of oil storage tank 2 respectively, and the bulkhead Both are steel double-hull watertight cylindrical welded structures, the inner and outer plates are welded with watertight steel plates, the distance between the inner and outer plates is on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com