Discharge mechanism of wire harness winding machine

A technology of unloading mechanism and cantilever, which is applied in the field of unloading mechanism behind the wire handle of industrial electric detonator, which can solve the problems of easily damaged wire covering and unreliable unloading, etc. The effect of reliable materials, improving reliability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

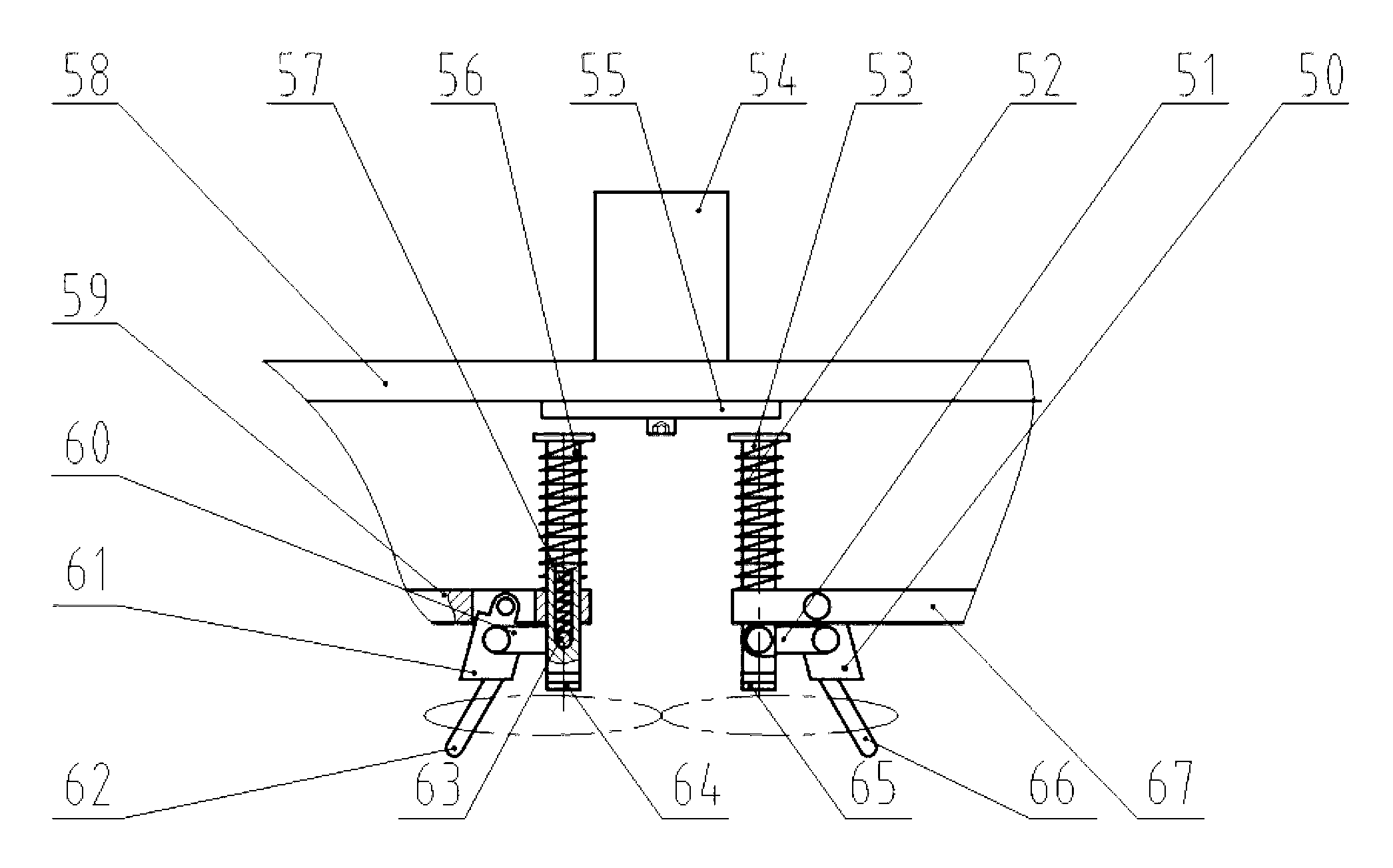

[0010] The invention provides an "8"-shaped handlebar unloading mechanism, which realizes product unloading through the movement of a cylinder and two plane four-bar mechanisms. First, use the cylinder to push the connecting rod of the connecting rod mechanism to move forward, and the connecting rod drives the handle head to loosen the two ends of the tensioned winding wire, and then the wound wire is removed through the action of the cylinder.

[0011] The handle machine discharge mechanism includes a handle base, a connecting rod, a discharge push shaft, a cylinder, a discharge push plate, a support plate, a cantilever, a handle base and a handle column.

[0012] The cylinder rod is connected with the unloading push plate, the unloading push shaft I and the unloading push shaft II can move linearly along the holes on the cantilever I and the cantilever II, the unloading push shaft I and the unloading push shaft II are connected with the cantilever I and the cantilever II A r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com