Slitting method of double-sided acrylic coated film

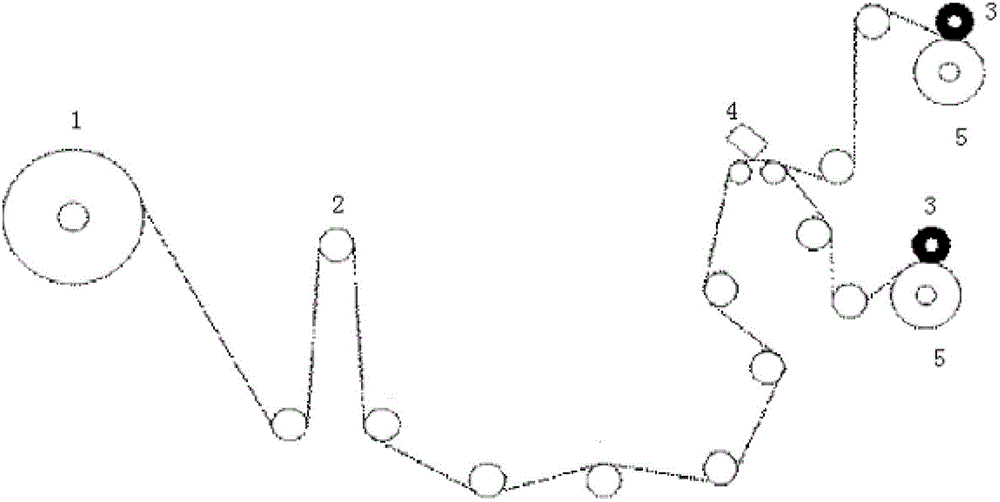

A technology of acrylic and coating film, which is applied in the direction of winding strips, sending objects, thin material processing, etc., and can solve the problems such as easy adhesion of roll film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

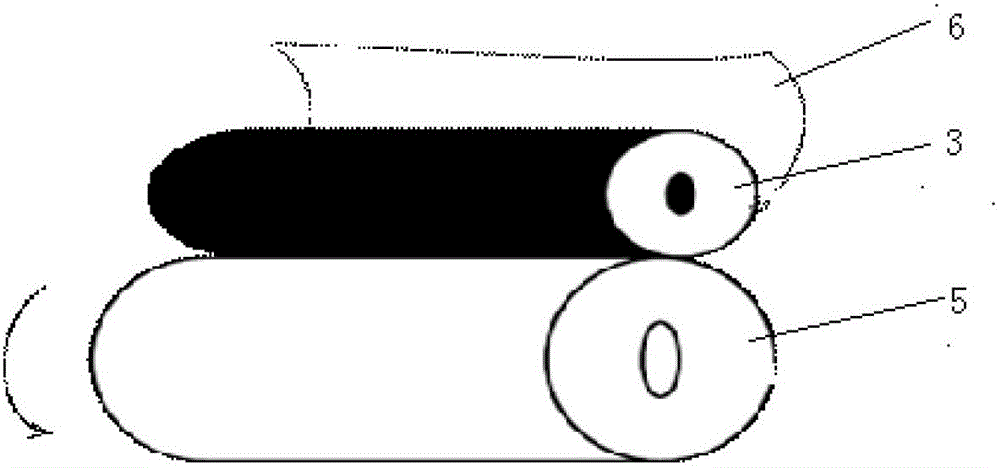

Embodiment 1

[0018] With BOPP as the base material, after double-sided coating of acrylic paint, the width of the coated film roll after winding is 1.36m, and cut into four small rolls of 340mm in size. The double-sided acrylic coated film to be cut Correctly install the unwinding shaft and inflate it to fix it, and string the film to the winding shaft through the guide roller, set the unwinding tension to 105N, the winding tension to 25N, set the weight of the pressure roller at the winding position to 4kg, and the machine speed Set to 250m / min. Turn on the machine, press the acceleration button to reach the set running speed, the film on the unwinding shaft runs to about 100m left, and then starts to slow down. After the film runs, just press the stop button and label the roll film. The end surface of the roll film after slitting is flat (the width difference is -0.1mm), and there is no adhesion phenomenon after being placed for 6 months, and the appearance is good.

Embodiment 2

[0020] With BOPP as the base material, after double-sided coating of acrylic paint, the width of the coated film roll after winding is 1.80m, and cut into four small rolls of 450mm in size. The double-sided acrylic coated film to be cut Correctly install the unwinding shaft and inflate it to fix it, and string the film to the winding shaft through the guide roller, set the unwinding tension to 150N, the winding tension to 45N, set the weight of the pressure roller at the winding position to 5kg, and the machine speed Set to 250m / min. Turn on the machine, press the acceleration button to reach the set running speed, the film on the unwinding shaft runs to about 100m left, and then starts to slow down. After the film runs, just press the stop button and label the roll film. The end surface of the roll film after slitting is flat (the width difference is -0.1mm), and there is no adhesion phenomenon after being placed for 6 months, and the appearance is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com