Method for preparing propylene glycol monomethyl ether by catalyzing alcoholysis of propylene epoxide

A technology of propylene glycol monomethyl ether and propylene oxide alcohol, which is applied to the preparation of ether from alkylene oxide, chemical instruments and methods, and ether preparation, etc., can solve the problems of inability to apply, harsh reaction conditions, and high reaction temperature, and is beneficial to industrial production. and application, the process is simple and easy to control, and the reaction conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019]In the preparation method provided by the present invention, the preferred ratio of raw materials is as follows: the molar ratio of propylene oxide to methanol is preferably 0.2-5.0:1, and the mass ratio of solvent to catalyst is preferably 5-200:1.

[0020] In the preparation method provided by the present invention, the reaction temperature is preferably 20-120° C., and the reaction pressure is preferably 0.1-1.5 MPa.

[0021] In the preparation method provided by the present invention, preferably, the contacting can be carried out in the presence of a solvent, and the mass ratio of the solvent to the catalyst is 0-1000:1. The solvent is preferably one or more of C3-C8 ketones, C1-C3 acids and C2-C8 nitriles. Further preferably, said solvent is selected from one or a mixture of acetonitrile, acetone and acetic acid. In addition, since propylene oxide is miscible with methanol, methanol can be used not only as a reaction raw material, but also as a solvent in the metho...

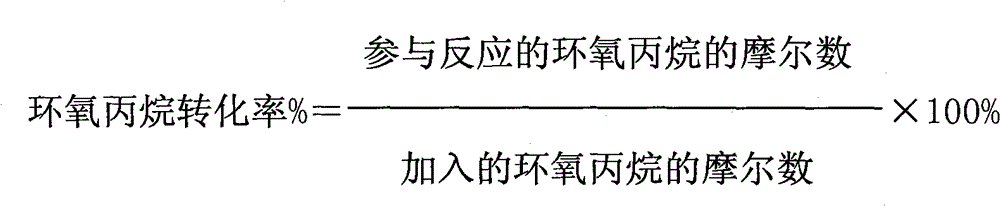

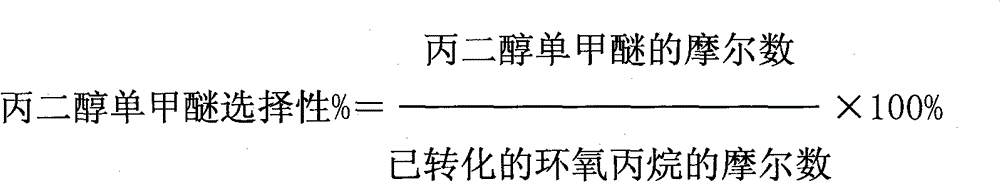

Embodiment 1

[0047] With propylene oxide, methyl alcohol, solvent acetone and catalyst (TS-1 and phosphotungstic heteropolyacid H 3 PW 12 o 40 The mass ratio of propylene oxide and methanol is 1: 2, the mass ratio of solvent acetone and catalyst is 20: 1, the mass ratio of propylene oxide and catalyst is 20: 1, at a temperature of 35 The reaction was carried out at ℃ and a pressure of 1.0 MPa.

[0048] The result of reacting for 1 hour is as follows: the conversion rate of propylene oxide is 67%; the selectivity of propylene glycol monomethyl ether is 84%.

Embodiment 2

[0050] With propylene oxide, methyl alcohol, solvent acetone and catalyst (TS-1 and phosphotungstic heteropolyacid H 3 PW 12 o 40 The mass ratio is 0.1: 1) according to the mol ratio of propylene oxide and methyl alcohol is 1: 2, the mass ratio of solvent acetone and catalyst is 120: 1, the mass ratio of propylene oxide and catalyst is 40: 1, at temperature The reaction was carried out at 50° C. and a pressure of 1.5 MPa.

[0051] The result of reacting for 1 hour is as follows: the conversion rate of propylene oxide is 73%; the selectivity of propylene glycol monomethyl ether is 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com