Method for preparing pentaerythritol stearate (PETS) by using illegal cooking oil

A technology of pentaerythritol stearate and gutter oil, which is applied in the field of oleochemical industry, can solve the problems of increasing the production cost of pentaerythritol stearate, lack of pre-treatment and fine separation process steps, and not being able to meet the requirements of pentaerythritol stearate. The effect of solving social pollution problems, reducing raw material costs, and huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

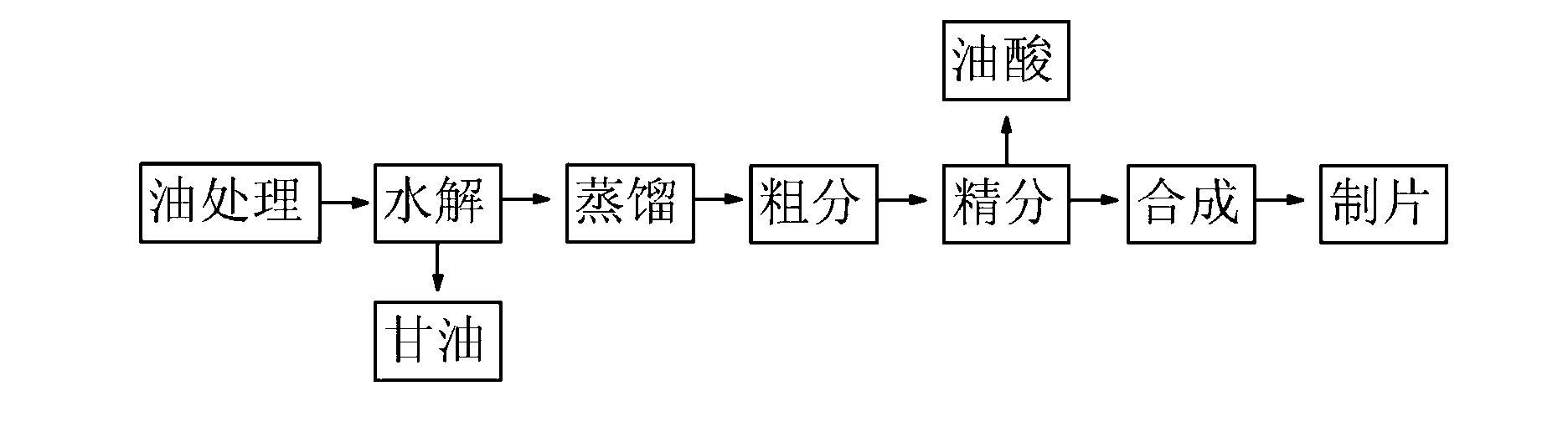

Image

Examples

Embodiment 1

[0025] 1. Early preprocessing:

[0026] A. Freezing: freeze the waste oil raw material in a freezing container at a freezing temperature of -5°C for 3 hours;

[0027] B. Filtration: filter the frozen waste oil raw material to obtain crystalline A and non-crystalline B products;

[0028] 2. Hydrolysis:

[0029] The A and B products obtained in step 1 are respectively hydrolyzed by physical hydrolysis, the hydrolysis pressure is 2.0MPa, and the hydrolysis temperature is 250°C; the time is 8 hours; after hydrolysis, the A and B products are correspondingly converted into crude acids C and D;

[0030] 3. Distillation:

[0031] Put the crude acid C and D obtained in step 2 into negative pressure distillation in the distillation pot respectively, the temperature is 220°C, and the negative pressure vacuum degree is negatively correlated with the temperature;

[0032] 4. Rough points:

[0033] The product of step 3 is roughly divided in a fractionating tower at a temperature of 23...

Embodiment 2

[0041] 1. Early preprocessing:

[0042] A. Freezing: freeze the waste oil raw material in a freezing container at a freezing temperature of -15°C for 2 hours;

[0043] B. Filtration: Filtrate the frozen waste oil raw material to obtain crystallization A and non-crystallization B products;

[0044] 2. Hydrolysis:

[0045] The A and B products obtained in step 1 are respectively hydrolyzed by physical hydrolysis, the hydrolysis pressure is 2.5MPa, and the hydrolysis temperature is 220°C; the time is 10 hours; after hydrolysis, the A and B products become crude acids C and D accordingly;

[0046] 3. Distillation:

[0047] Put the crude acids C and D obtained in step 2 into negative pressure distillation in the distillation pot respectively, the temperature is 240°C, and the negative pressure vacuum degree is negatively correlated with the temperature;

[0048] 4. Rough points:

[0049] The product of step 3 is roughly divided in a fractionating tower at a temperature of 240° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com