Highly metallic resin composition and preparation method thereof

A resin composition and high metal technology, applied in the field of resin composition with high metal texture and its preparation, can solve the problems such as molding products not having high-end appearance, complicated equipment maintenance, decreased metal texture, etc., and achieve obvious market application prospects , The effect of simple process operation and increased equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

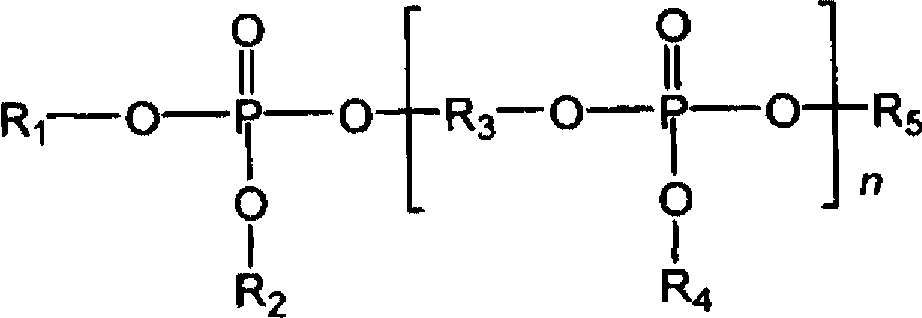

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a resin composition with high metallic texture, the preparation method of which comprises the following steps:

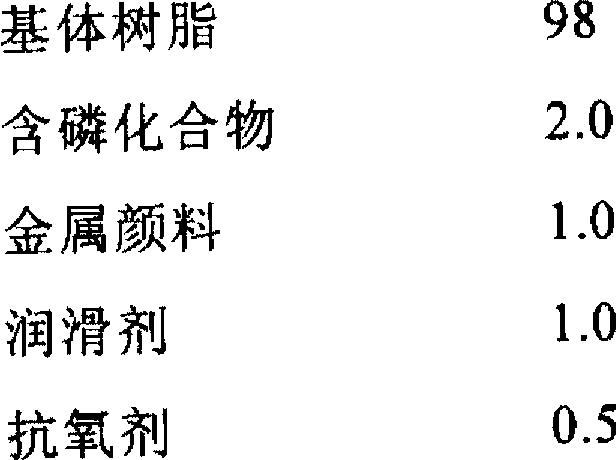

[0039] (1) Prepare materials according to the following components and parts by weight:

[0040]

[0041] Among them, the matrix resin is ABS750 of Korea Kumho Petroleum Co., Ltd.;

[0042] Phosphorus-containing compound is Daba Chemical BAPP

[0043] Metallic pigment is aluminum powder, particle size 45μm, coated with acrylic acid

[0044] The lubricant is PETS;

[0045] The antioxidant is B900.

[0046] (2) After the matrix resin, phosphorus-containing compounds, metal pigments, antioxidants, and lubricants are fully mixed in a low-speed mixer, they are sent into the twin-screw extruder through a metering device, and are transported and sheared by the screw. Under mixing and mixing, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain the resin composition 1 with high metallic tex...

Embodiment 2

[0048] This embodiment provides a resin composition with high metallic texture, the preparation method of which comprises the following steps:

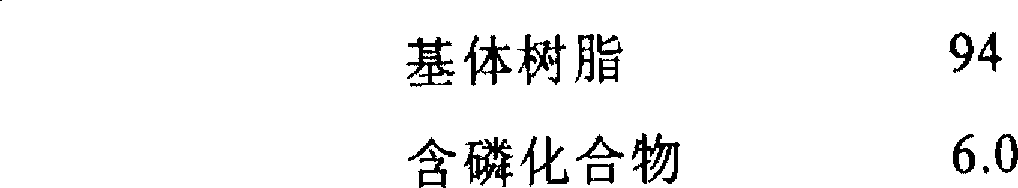

[0049] (1) Prepare materials according to the following components and parts by weight:

[0050]

[0051]

[0052] Among them, the matrix resin is ABS750 of Korea Kumho Petroleum Co., Ltd.;

[0053] Phosphorus-containing compound is Daba Chemical BAPP

[0054] Metallic pigment is aluminum powder, particle size 45μm, coated with acrylic acid

[0055] (2) After the matrix resin, phosphorus-containing compounds, metal pigments, antioxidants, and lubricants are fully mixed in a low-speed mixer, they are sent into the twin-screw extruder through a metering device, and are transported and sheared by the screw. Under mixing and mixing, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain a resin composition 2 with high metallic texture.

Embodiment 3

[0057] This embodiment provides a resin composition with high metallic texture, the preparation method of which comprises the following steps:

[0058] (1) Prepare materials according to the following components and parts by weight:

[0059]

[0060] Among them, the matrix resin is transparent ABS;

[0061] Phosphorus-containing compound is Daba Chemical BAPP

[0062] Metallic pigment is aluminum powder, particle size 45μm, coated with acrylic acid

[0063] (2) After the matrix resin, phosphorus-containing compounds, metal pigments, antioxidants, and lubricants are fully mixed in a low-speed mixer, they are fed into a twin-screw extruder through a metering device. Under mixing and mixing, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain a resin composition 3 with high metal texture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com