Dewaxing and degreasing method of shellac resin

A technology of shellac resin and shellac wax, which is applied in the refining of natural resins, etc., can solve problems such as wax solidification and catheter blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

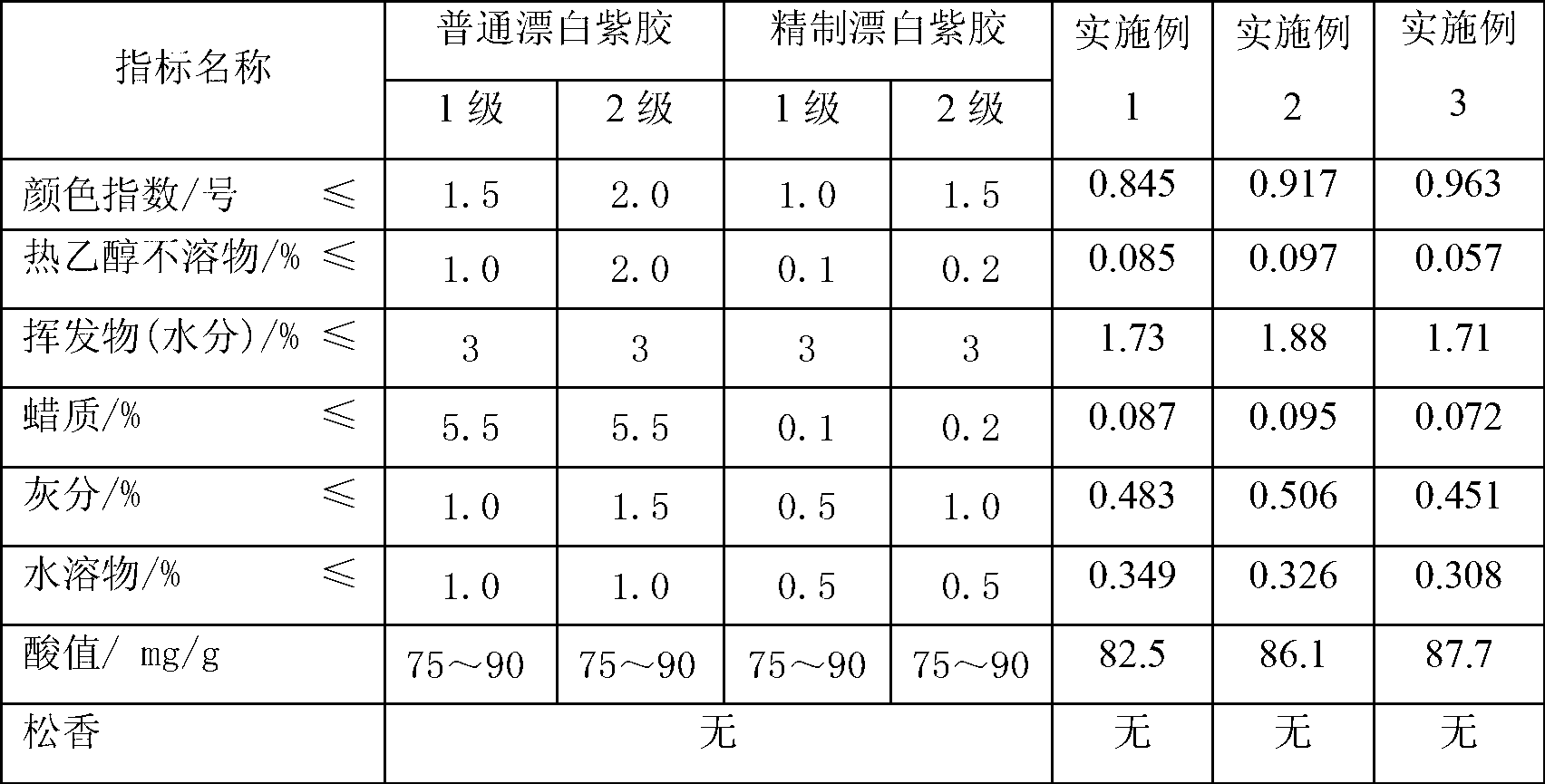

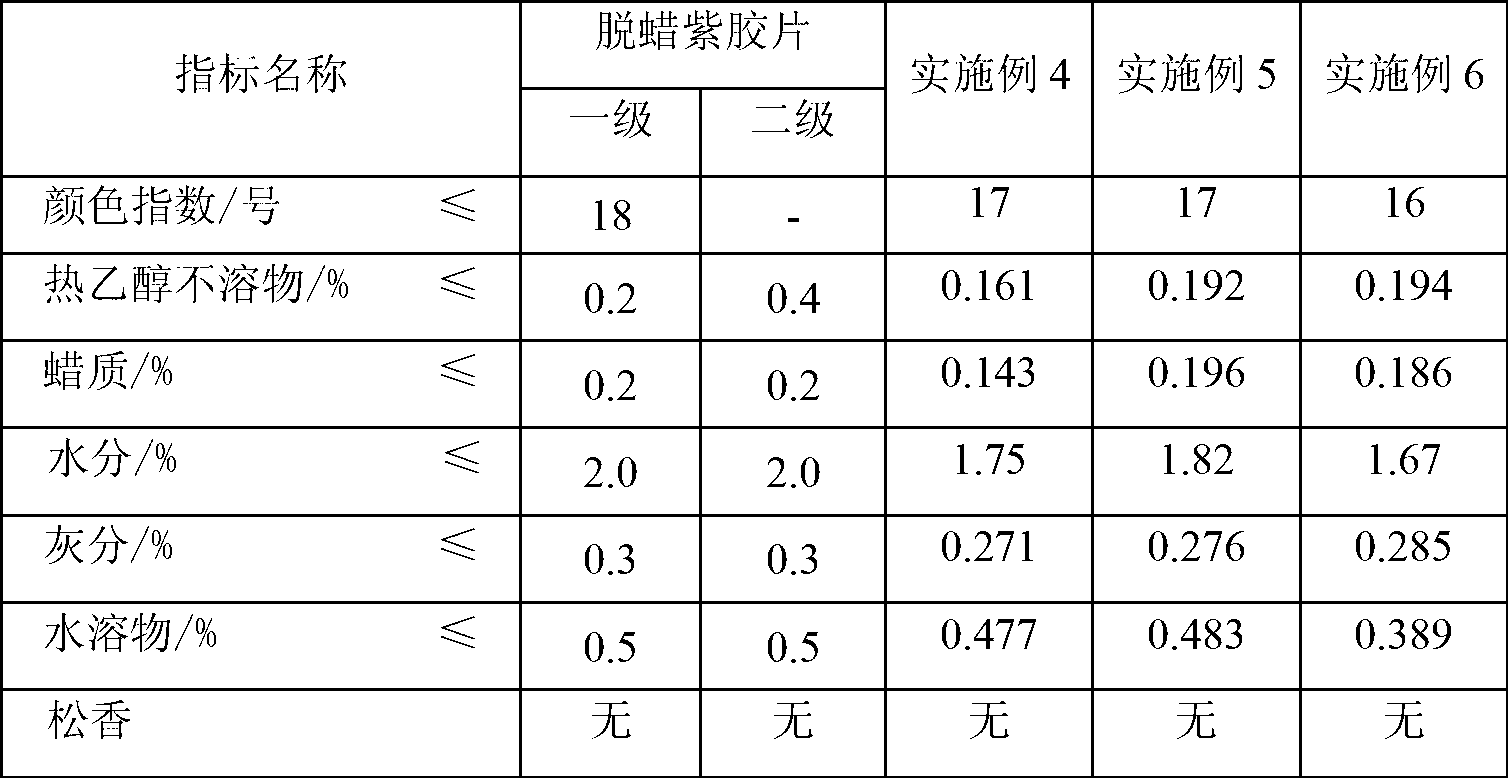

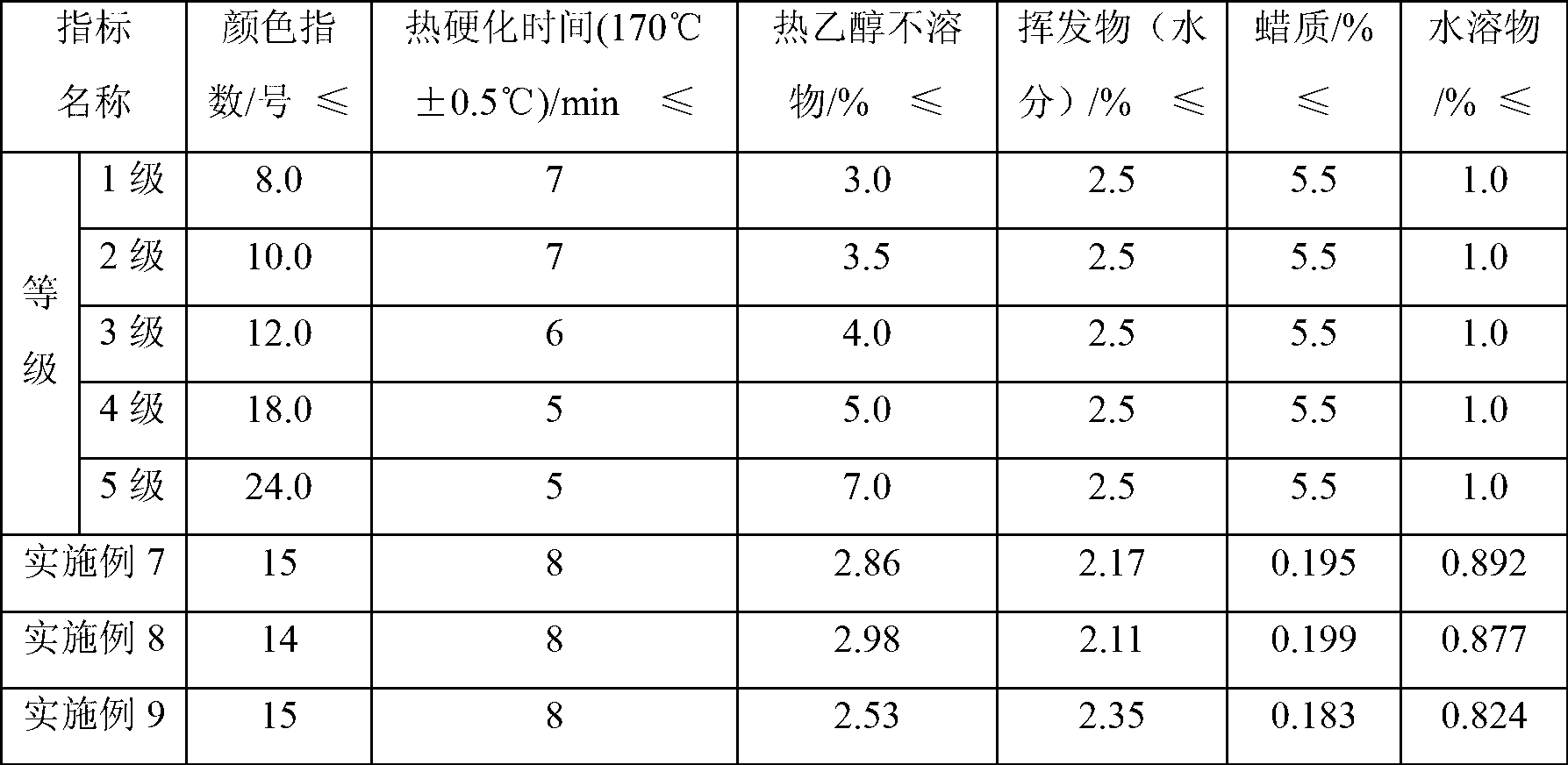

Examples

Embodiment 1

[0090] 1. Preparation of lac resin-sodium carbonate solution

[0091]1A. Crush the lacella gum (purple stem) into granules with a particle size of 4-6 mm, and remove impurities such as branches and sand through a circular pendulum sieve;

[0092] 1B. Add 8 kg of pulverized lacella gum particles to 100 L of sodium carbonate aqueous solution with a concentration of 0.15 mol / L, heat and keep the temperature at 90 ° C, and filter to remove mechanical impurities under the condition of keeping the temperature at 90 ° C after stirring and dissolving to obtain Shellac resin-sodium carbonate solution, wherein, the ratio of the weight of shellac gum to the volume of sodium carbonate aqueous solution is 8:100, namely the shellac gum of 0.08kg is added in every 1L described sodium carbonate aqueous solution or every 100mL described sodium carbonate Add 8g of shellac gum to the aqueous solution; the temperature of the shellac resin-sodium carbonate solution is 90°C;

[0093] 2. The first ...

Embodiment 2

[0117] 1. Preparation of lac resin-sodium carbonate solution

[0118] 1A. Crush the lacella gum (purple stem) into granules with a particle size of 4-6 mm, and remove impurities such as branches and sand through a circular pendulum sieve;

[0119] 1B. Add 11kg of crushed shellac gum particles to 100 L of sodium carbonate aqueous solution with a concentration of 0.10 mol / L, heat and keep the temperature at 90°C, and filter to remove mechanical impurities after stirring and dissolving and keeping the temperature at 90°C to obtain Shellac resin-sodium carbonate solution, wherein, the ratio of original collagen weight to the volume of sodium carbonate aqueous solution is 11:100, promptly add the shellac gum of 0.11kg in every 1L described sodium carbonate aqueous solution or every 100mL described sodium carbonate Add 11g of shellac gum to the aqueous solution; the temperature of the shellac resin-sodium carbonate solution is 90°C;

[0120] 2. Crystallization treatment

[0121]Th...

Embodiment 3

[0128] 1. Preparation of lac resin-sodium carbonate solution

[0129] 1A. Crush the lacella gum (purple stem) into granules with a particle size of 1-4 mm, and remove impurities such as branches and sand through a circular pendulum sieve;

[0130] 1B. Add 5 kg of pulverized lacella gum particles to 100 L of sodium carbonate aqueous solution with a concentration of 0.15 mol / L, heat and keep the temperature at 85 ° C, and filter to remove mechanical impurities under the condition of keeping the temperature at 85 ° C after stirring and dissolving to obtain Shellac resin-sodium carbonate solution, wherein, the ratio of the weight of shellac gum to the volume of sodium carbonate aqueous solution is 5:100, promptly add 0.05kg shellac gum or every 100ml described sodium carbonate solution in every 1L described sodium carbonate aqueous solution 5g of shellac gum was added to the aqueous solution; the temperature of the prepared shellac resin-sodium carbonate solution was 85°C;

[013...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com