Harmless recycling treatment method and special device for oil sand

A treatment method and resource recovery technology, which is applied in the field of oil sand harmless resource recovery and special equipment, can solve the problems of high wax content, waste of resources, increase of waste gas emissions, etc., and achieve multiple varieties and strong practicability , the effect of restoring land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

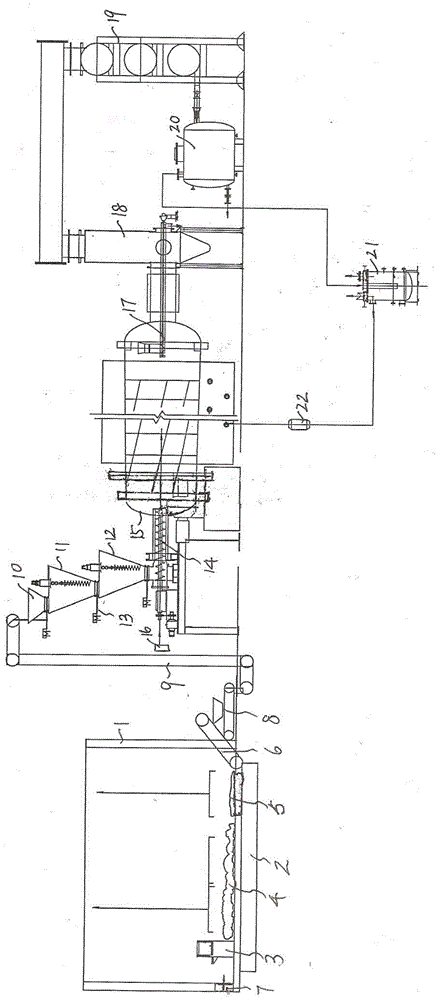

Image

Examples

Embodiment Construction

[0038] A method for harmless and resourceful treatment of oil sands, comprising the following steps:

[0039] (1) Use waste heat to dehydrate oil sand

[0040] The oil sand warehouse 1 is set up, and the warehouse adopts steel structure insulation walls and color steel tile insulation roofs; under the floor of the oil sand warehouse, there is a waste heat flue 2 to transfer the waste heat of the flue gas to the floor; the floor is supported by load-bearing steel, absorbs Hot sheet steel plate; steam heater 7 is installed on the wall of the warehouse to continuously provide hot air flow to the warehouse to stabilize the temperature of the warehouse; rely on the slope of the steel plate and special pipelines to collect the oily sewage that has been removed and send it to the sewage pool to separate the oily sewage collection pipe ditch, and send the sewage to to the waste water tank; the oil sand first passes through the pulverizer 3 to crush the waste plastics and rubber; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com