Ethylene Cracking Raw Material by Hydrogenation of Light C5 Distillate

A carbon five fraction and ethylene production technology, which is applied in the field of cracking raw materials for ethylene production, can solve the problems of accelerating the polymerization reaction of diolefins and alkynes, losing the catalytic and adsorption functions of sulfide, and achieving the effect of high sulfur removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

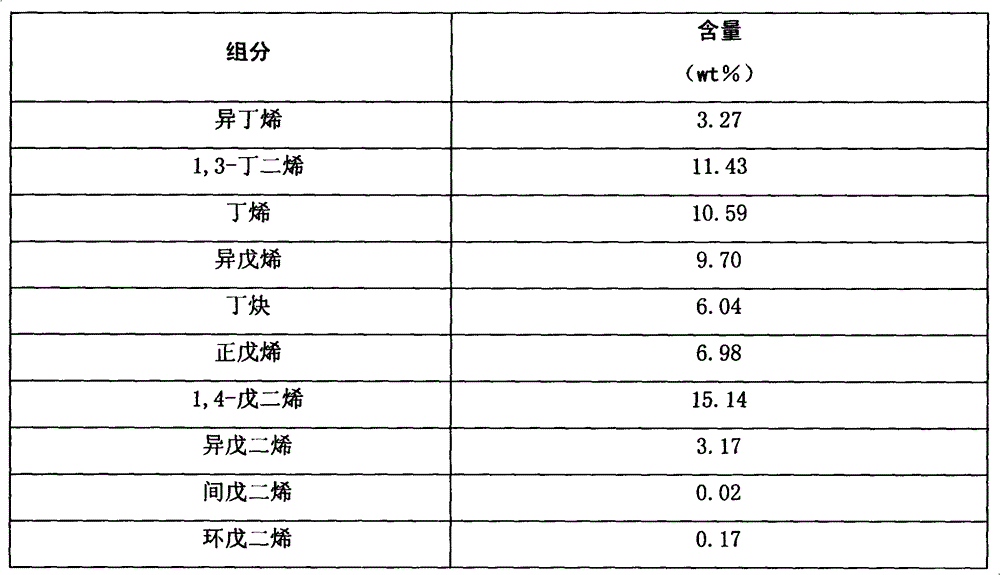

Embodiment 1~10

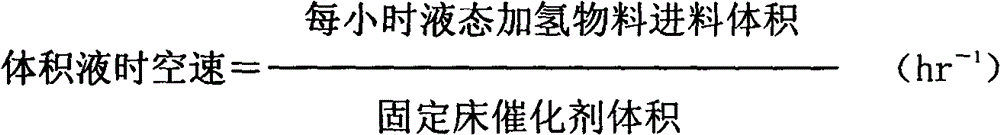

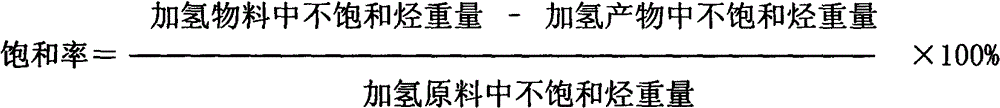

[0029]The hydrogenation reaction is carried out in a stainless steel tubular reactor, and the reactor is a stainless steel tubular reactor with a size of φ25mm×1000mm. Fill the reaction tube with 100mL hydrogenation catalyst to form a fixed bed. The hydrogenation catalyst is a supported catalyst with Ni as the active component and diatomaceous earth as the carrier. The weight percentage of Ni in the catalyst is 30-50%. The bottom is filled with inert ceramic balls. The fresh catalyst needs to be activated with hydrogen before feeding.

[0030] The desulfurization treatment of the hydrogenation product is carried out in a stainless steel tubular reactor with a size of φ25mm×1000mm. Fill the reactor with 200mL desulfurizer to form a fixed bed. Desulfurization agent is Cu 2+ Modified Y-type molecular sieve, the particle size is 3-6mm, Cu in the molecular sieve 2+ The content is shown in Table 2. The desulfurizer is dehydrated before operation, and the bed can be purged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com