A kind of xanthate compatibility flotation agent and using method thereof

A flotation reagent and xanthate technology, applied in flotation, solid separation, etc., can solve the problems of limited xanthate application, short storage time, poor mineral selectivity, etc., increase mineral recovery rate, reduce beneficiation cost, and reduce toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

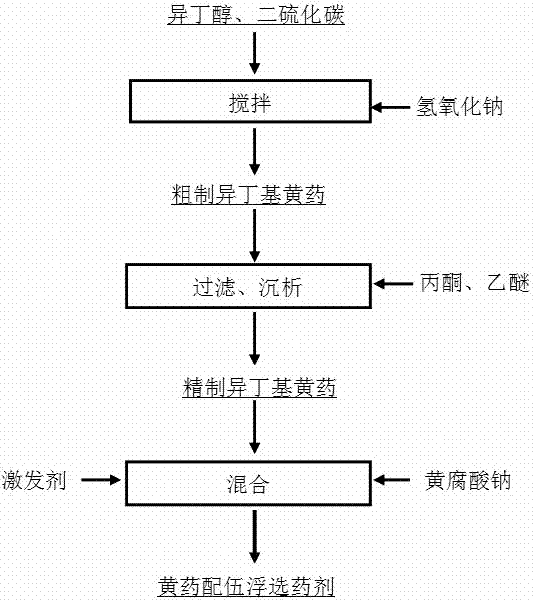

Method used

Image

Examples

Embodiment 1

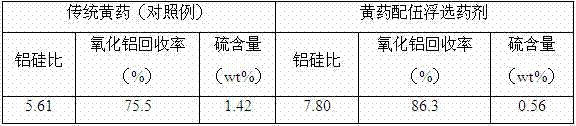

[0018] Xanthate compatibility flotation agent is composed of the following three substances in weight percentage: 80% refined isobutyl xanthate, 15% bistrifluoromethanesulfonimide, and 5% sodium fulvic acid . When using xanthate-compatible flotation agent to float high-sulfur bauxite (aluminum-silicon ratio is 3.23, sulfur content is 2.08wt%), add xanthate-compatible flotation agent to particle size ≤0.074mm to reach 85% (mass percentage) In the bauxite slurry, stirring, adding water to adjust the slurry (pulp concentration 40wt%), scraping flotation, the dosage of flotation agent is 100 g per ton of ore. The specific results are shown in Table 1.

[0019] Table 1 Index comparison before and after applying this embodiment

[0020]

Embodiment 2

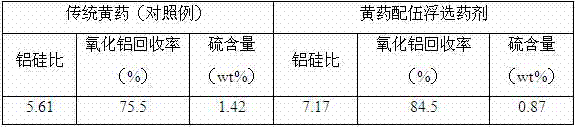

[0022] The xanthate compatibility flotation agent is composed of the following three substances in weight percentage: 85% by weight of refined isobutyl xanthate, 10% of bistrifluoromethanesulfonimide, and 5% of sodium fulvic acid. When using xanthate-compatible flotation agent to float high-sulfur bauxite (aluminum-silicon ratio is 3.23, sulfur content is 2.08%), add xanthate-compatible flotation agent to reach 85% (mass percentage) of particle size ≤0.074mm In the bauxite slurry, stirring, adding water to adjust the slurry (slurry concentration 40wt%), scraping flotation, and the dosage of xanthate-compatible flotation agents is 80 g per ton of ore. The specific results are shown in Table 2.

[0023] Table 2 Index comparison before and after applying this embodiment

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com