Wet reactor capable of realizing total sulfur removal of blast furnace gas

A blast furnace gas and reactor technology, which is applied in the removal of gas pollutants, combustible gas purification, combustible gas purification/transformation, etc., can solve the problem that there is no technical report or engineering case for total sulfur removal from blast furnace gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

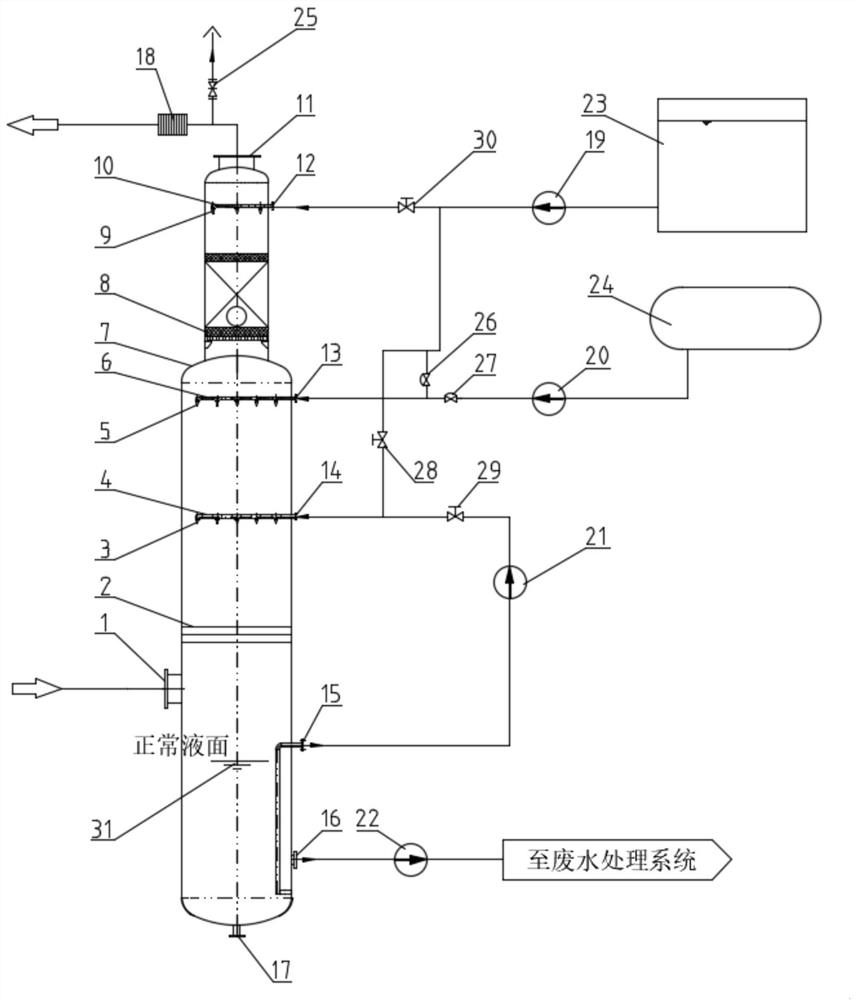

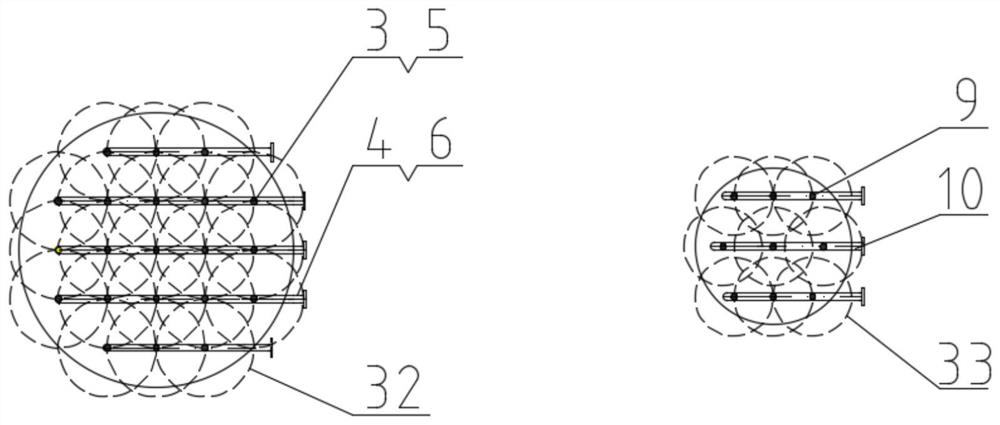

[0035] Such as figure 1 As shown, a wet reactor capable of removing all sulfur from blast furnace gas is preferably a wet reactor capable of realizing H in blast furnace gas 2 S, SO 2 A wet reactor for the removal of sulfur-containing substances such as sulfur-containing substances and the coordinated removal of HCl, which includes a shell 7, which contains a water seal device 31, a blast furnace gas inlet 1, an air flow uniform device 2, and Circulating water spraying device 4, lye spraying device 6, demister 8, flushing water spraying device 10 and blast furnace gas outlet 11; the side of wet reactor shell 7 is provided with waste liquid outlet 16, The circulating water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com