Blast Furnace Burden Optimization Method and System Based on Pattern Recognition and Expert System

A pattern recognition and expert system technology, which is applied in the field of blast furnace material distribution optimization and large-scale blast furnace process control, can solve the problems of limiting the speed and quality of expert system development for material distribution control, restricting blast furnace production efficiency and capacity, and low learning and maintenance capabilities. Achieve the effect of improving gas utilization rate, reducing blast furnace fuel ratio, and avoiding big ups and downs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

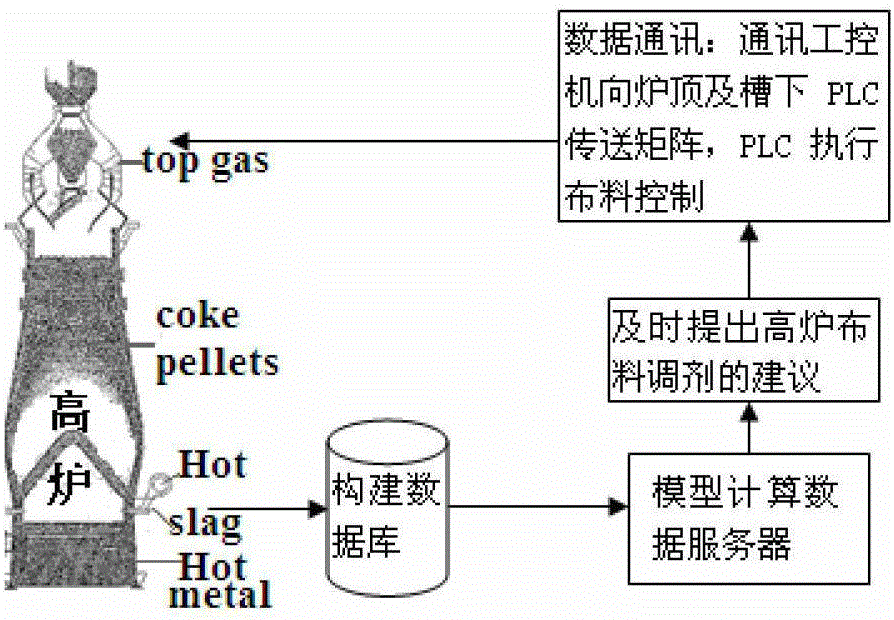

[0027]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

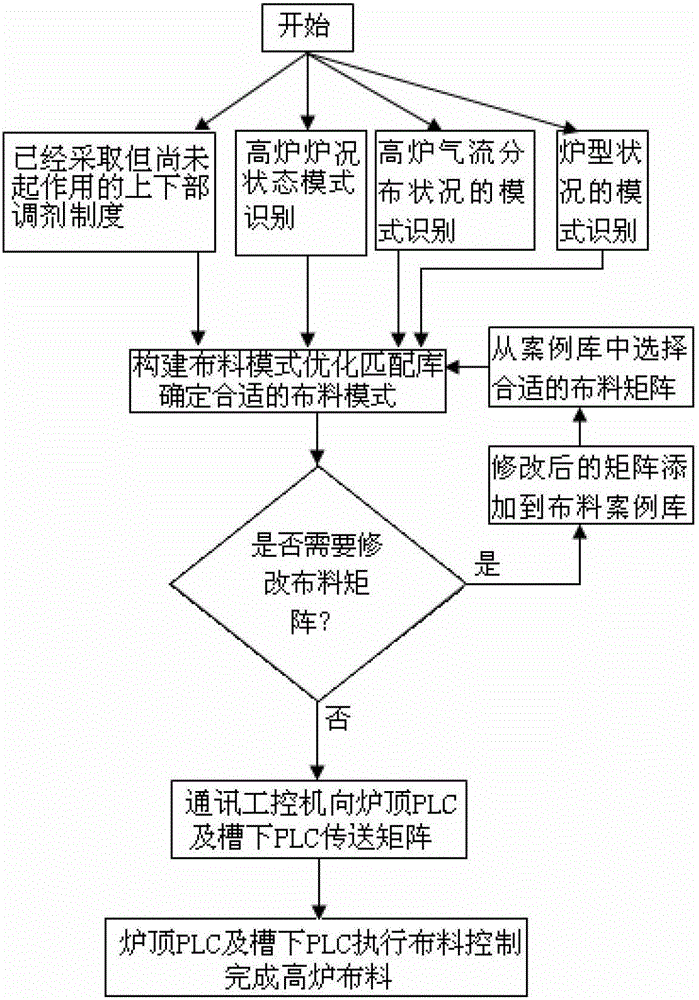

[0028] Such as figure 1 The shown optimization method of blast furnace material distribution based on pattern recognition and expert system includes the following steps:

[0029] S1. Construct condition case base: Construct pattern recognition of airflow distribution in blast furnace, pattern recognition of furnace type change and pattern recognition of blast furnace condition;

[0030] In the above S1: Constructing the pattern recognition of the airflow distribution: Obtain the 6-month airflow distribution data from the database, use the temperature of the blast furnace riser tube or the infrared measurement image of the furnace top as the measurement data of the airflow distribution, and use the pattern recognition technology to map the furnace top Airflow changes are divided into 25 categories (or 36, 49 categories);

[0031] Construct the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com