Crystallizer trolley special for electroslag furnace

A technology of crystallizer and electroslag furnace, applied in the field of crystallizer base, which can solve problems such as equipment damage, poor quality of electroslag ingots, and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

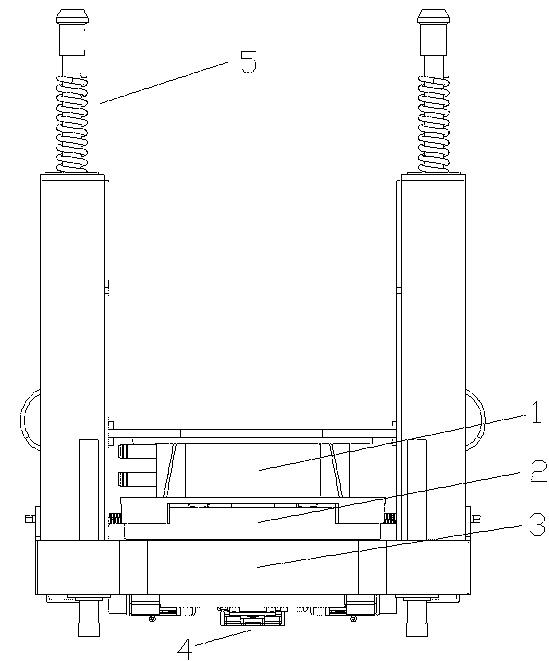

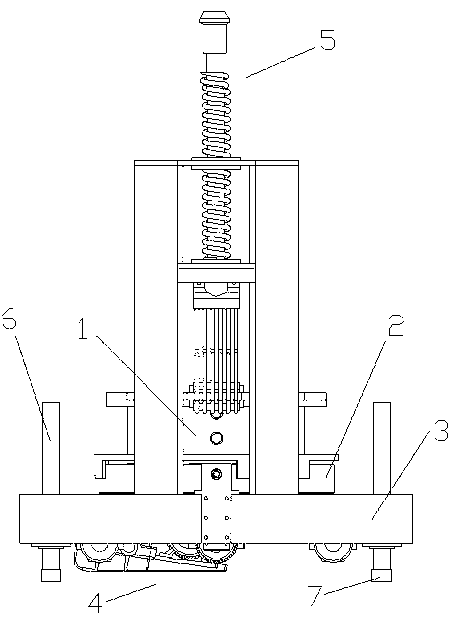

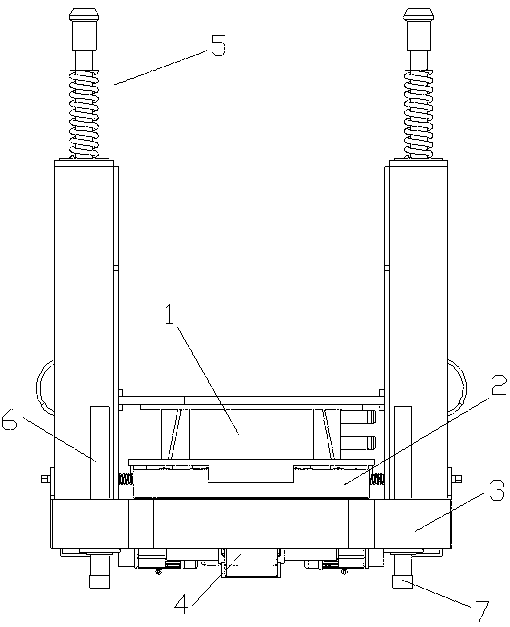

[0020] Depend on Figure 1 to Figure 4 It can be seen that this special crystallizer trolley for electroslag furnace includes a low water tank 1, a lifting platform 3, a pole mechanism 5, and a running mechanism 4. The running mechanism 4 is installed at the lower part of the lifting platform 3. A speed motor, a gearbox, a driving wheel and a guide rail, the speed regulating motor is connected with the gearbox, the gearbox is connected with the driving wheel, and the driving wheel is arranged on the guide rail. The gearbox is driven by a speed-regulating motor to drive the drive wheel to move left and right on the guide rail, completing the task of carrying the crystallizer in and out of the station on the trolley and fine-tuning the X-axis distance. The special mold trolley for electroslag furnace with this structure has moved the hoisting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com