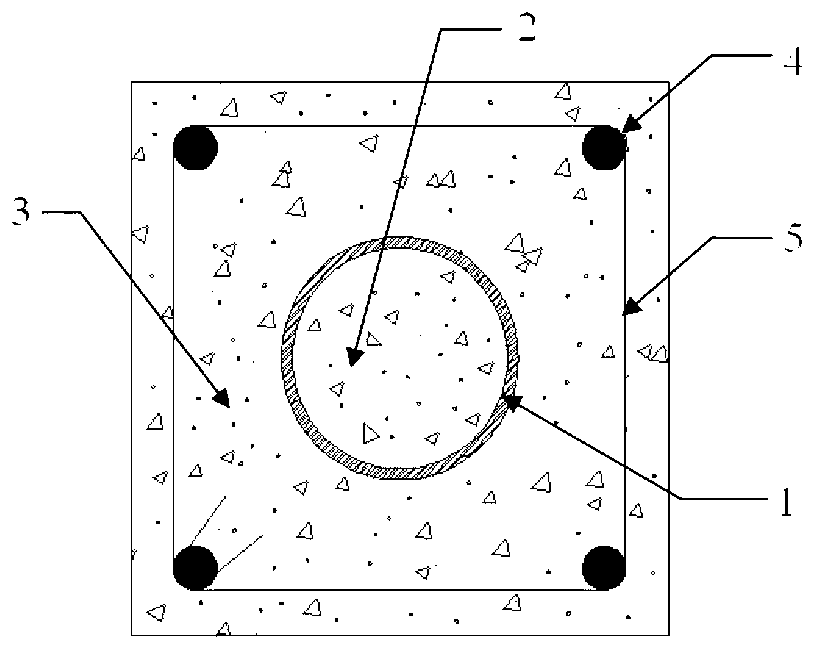

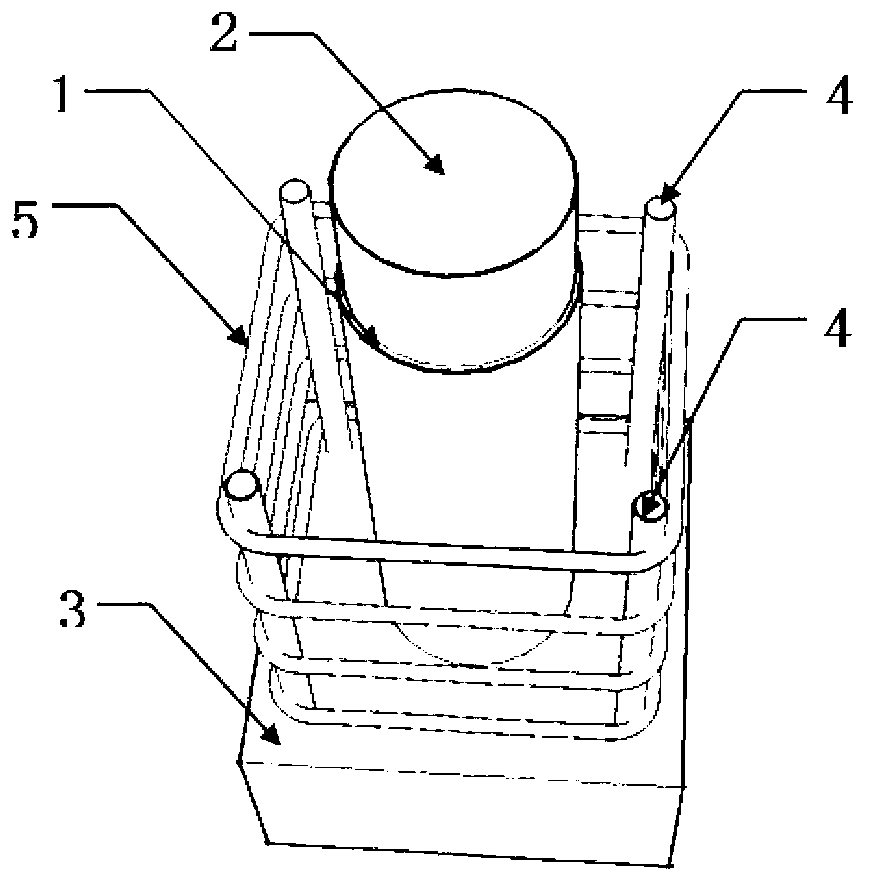

Built-in polyvinyl chloride (PVC) pipe enhanced reinforced concrete combined column

A reinforced concrete column, reinforced concrete technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of increasing steel consumption and construction costs, and achieve the effects of improving durability, high quality and cost performance, and reducing relative cross-sectional size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] PVC (Poly Vinyl Chloride) material has good processing performance, low manufacturing cost, corrosion resistance, insulation and other good characteristics and relatively excellent geometric stability. Generally speaking, PVC pipe has good physical and mechanical properties, its tensile yield strength is ≥40MPa, and its elastic modulus is about 2749MPa.

[0022] When the composite column is a small high-rise or a high-rise building's bottom-floor column or several lower-story columns, the load (including bending moment, shear force and axial force) transmitted from the upper part is relatively large, especially the influence of axial force on the column section size , and in order to meet the requirements of the limit value of the axial compression ratio required for the earthquake resistance of the building structure, the column section must have a very high bearing capacity. An effective means to increase the bearing capacity is to increase the ratio of the sum of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com