Mechanical sealing device of high-pressure water injection pump

A mechanical seal device and water injection pump technology, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as deformation of the end face of graphite seal rings, shortened seal life, and partial erosion of seals , to achieve uniform thrust distribution, avoid precision errors, and small axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

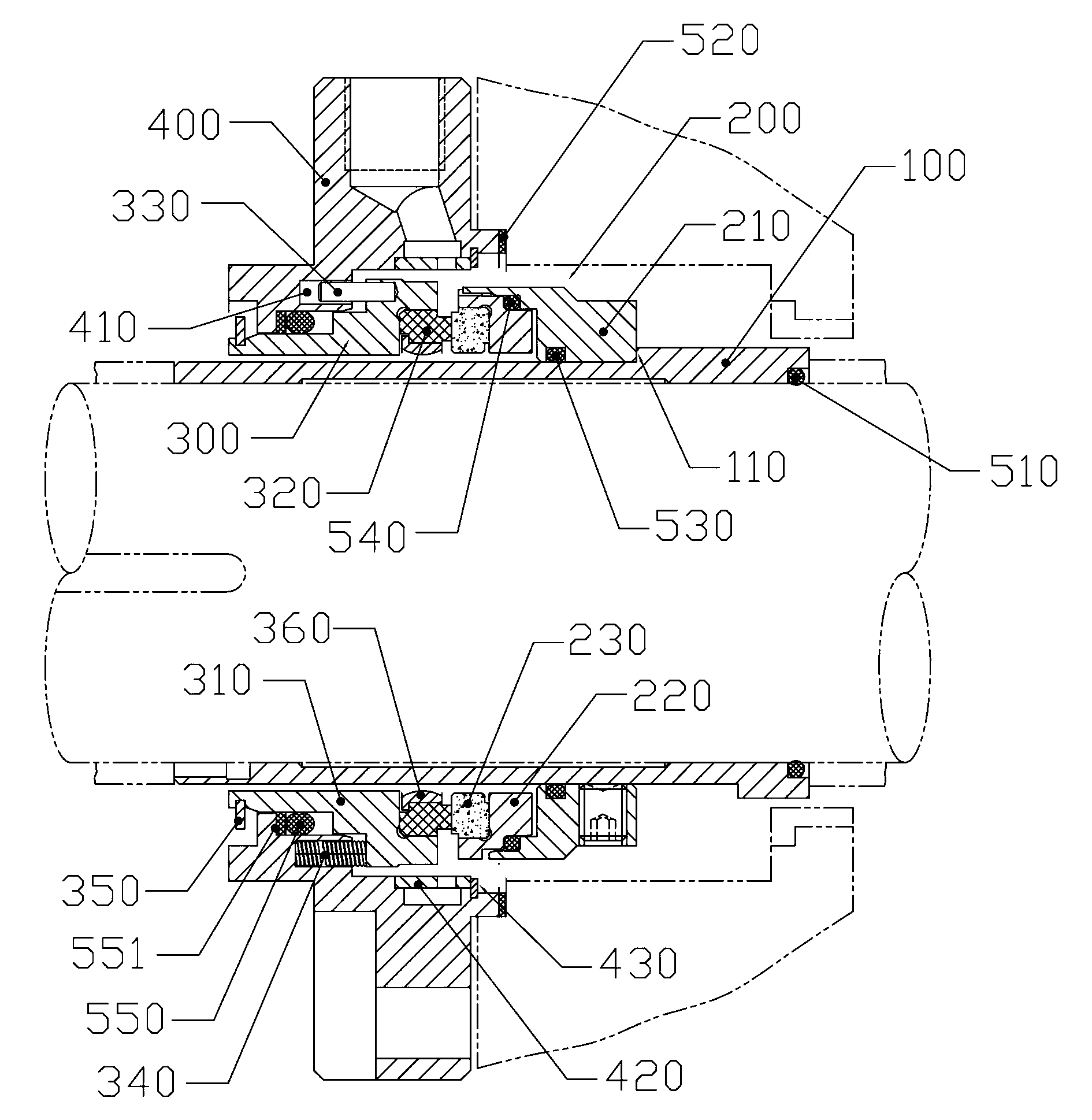

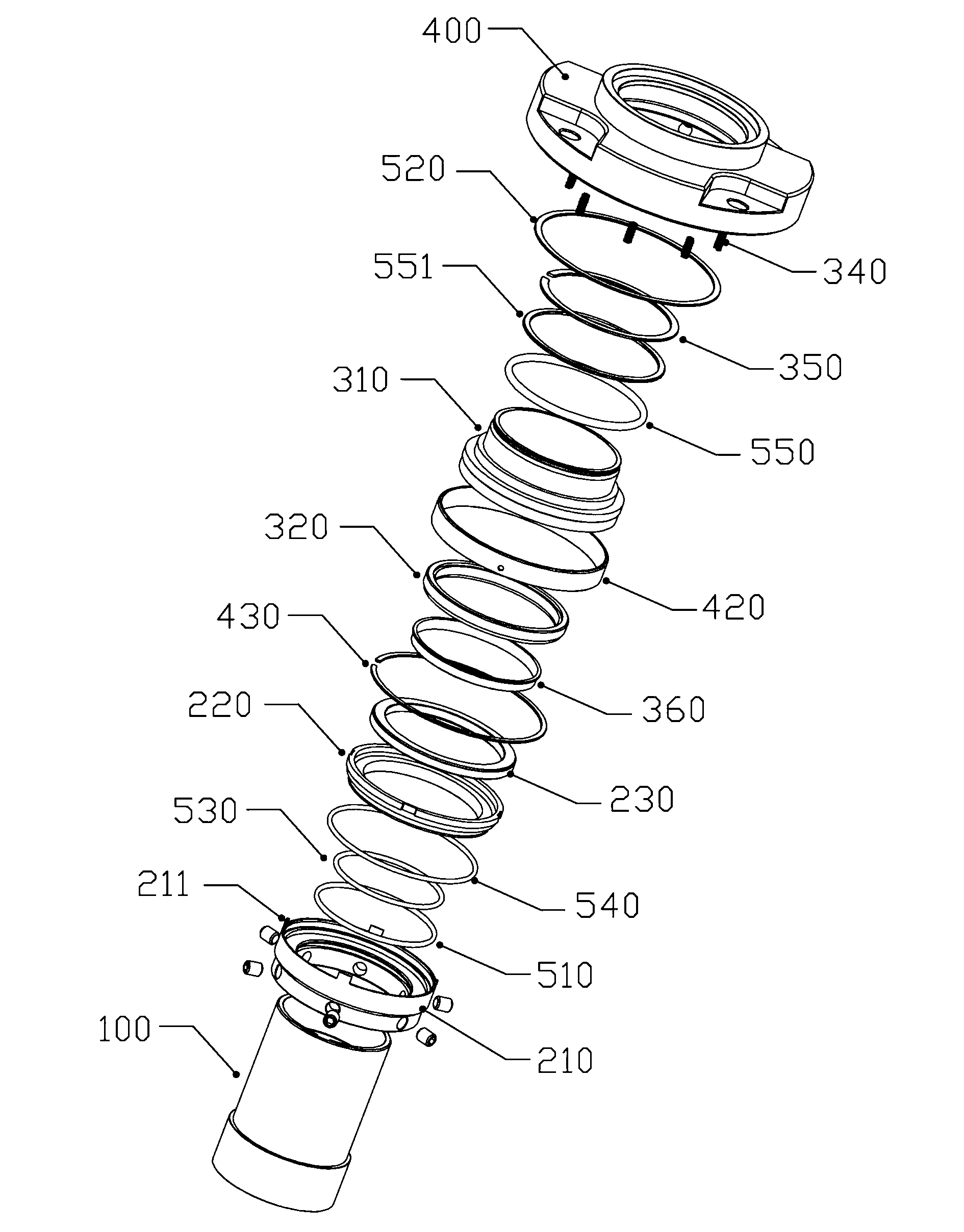

[0019] refer to figure 1 and figure 2 , a mechanical seal device for a high-pressure water injection pump, including a shaft sleeve 100, a moving ring assembly 200, an elastic compensation assembly 300, a sealing gland 400, and an auxiliary seal. There is a first seal between the shaft sleeve 100 and the pump shaft. An O-ring 510, and a gasket 520 for sealing between the sealing gland 400 and the pump body.

[0020] The moving ring assembly 200 is fixed on the outer wall of the shaft sleeve 100 by screws 210, the shaft sleeve 100 is provided with a step 110, one end of the moving ring assembly 200 abuts against the step 110, and there is a gap between the moving ring assembly 200 and the shaft sleeve 100 for The second O-ring 530 for sealing.

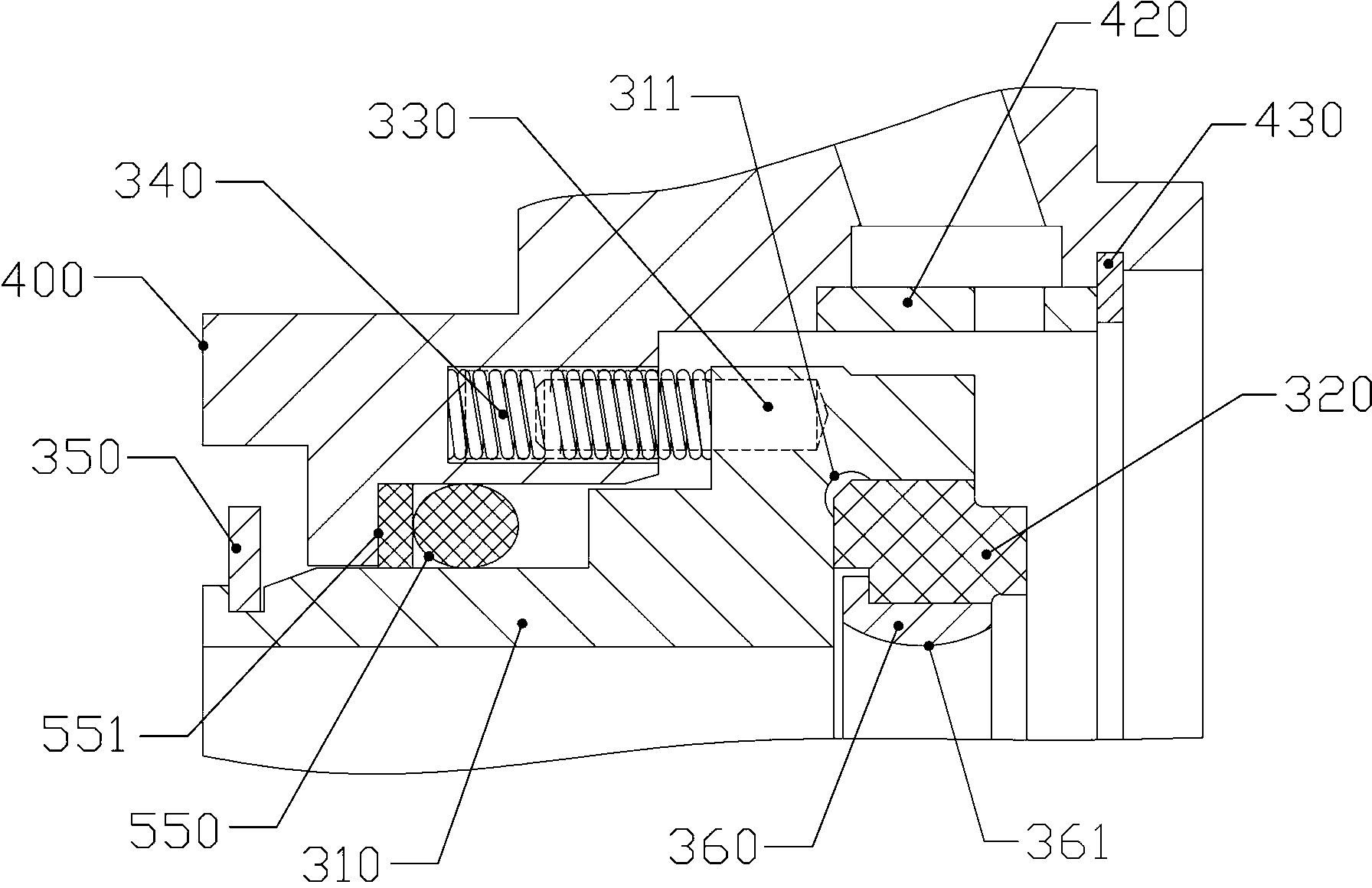

[0021] refer to image 3 , the elastic compensator assembly 300 includes a stationary ring seat 310, a stationary ring 320 inlaid on the stationary ring seat 310, an anti-rotation pin 330 axially arranged at one end of the stationar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com