Waste gas dry purifying device for CVD (chemical vapor deposition) on-line function film plating

A dry purification and functional membrane technology, which can be used in combination devices, incinerators, combustion methods, etc., can solve the problem of not being able to deal with coating waste gas and water pollution at the same time, and achieve the elimination of water pollution, wide application prospects and high purification efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

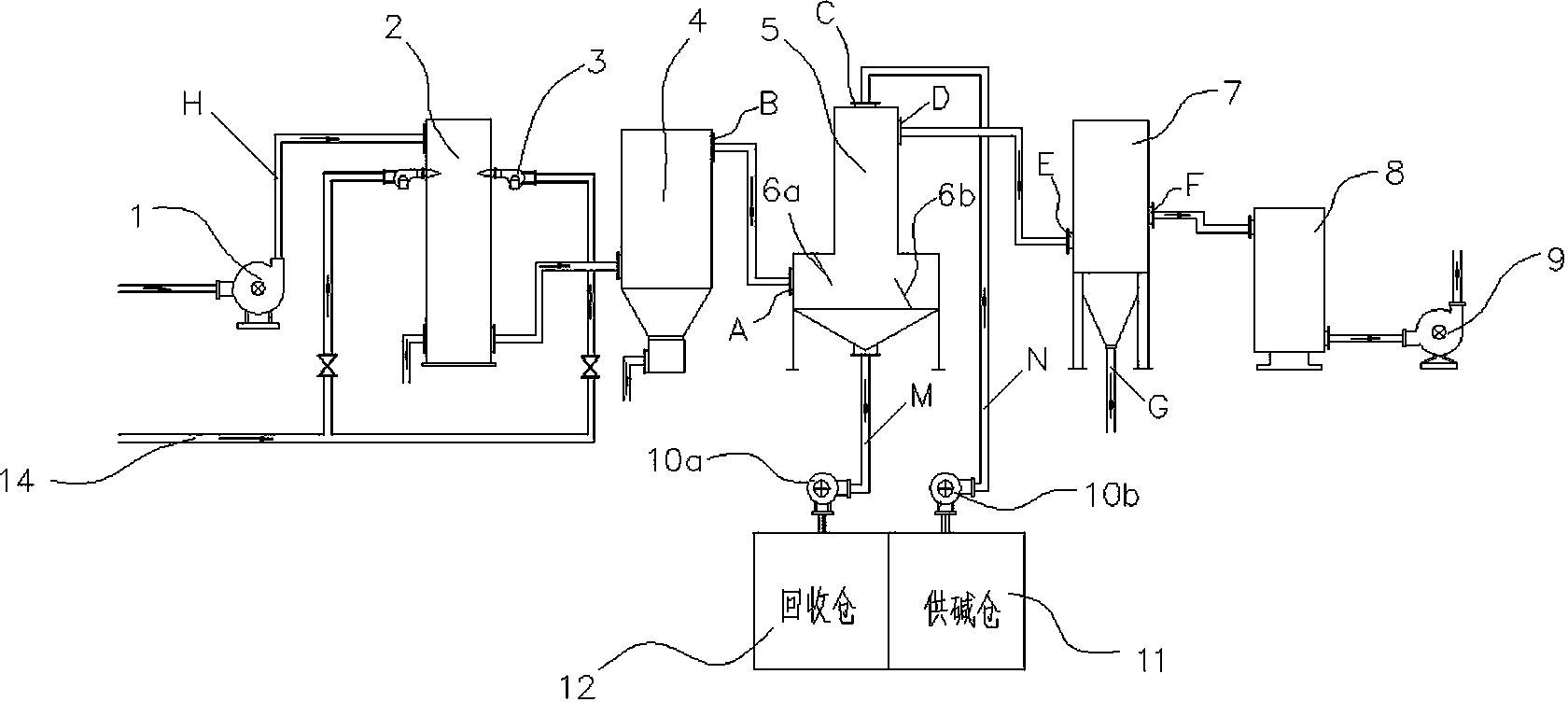

[0011] Such as figure 1 As shown, a CVD on-line coating functional film exhaust gas dry purification device provided by the present invention includes a gas source pipeline H, which is connected to the combustion chamber 2, and a frequency conversion exhaust gas fan 1 is connected to the gas source pipeline H, and in the combustion chamber Both sides of 2 are respectively connected with a burner 3, and the burner is connected with external fuel through a fuel pipeline 14. The combustion chamber 2 is connected to the ultra-high temperature electrostatic precipitator 4 through pipelines, and a discharge port is arranged at the lower end of the ultra-high temperature electrostatic precipitator 4 . The ultra-high temperature electrostatic precipitator 4 is connected to the activated carbon fiber purifier 8 through the pipeline, and the activated carbon fiber purifier 8 is connected to the induced draft fan 9 through the pipeline, which is characterized in that it also includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com