Method for preparing activated carbon for industrial wastewater treatment by using one-step process

A technology for preparing activated carbon and industrial wastewater, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of insufficient utilization of weak alkaline active agents, complex preparation process, and waste of resources To achieve the effect of eliminating soil pollution and water pollution, simple process and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A specific example of the present invention:

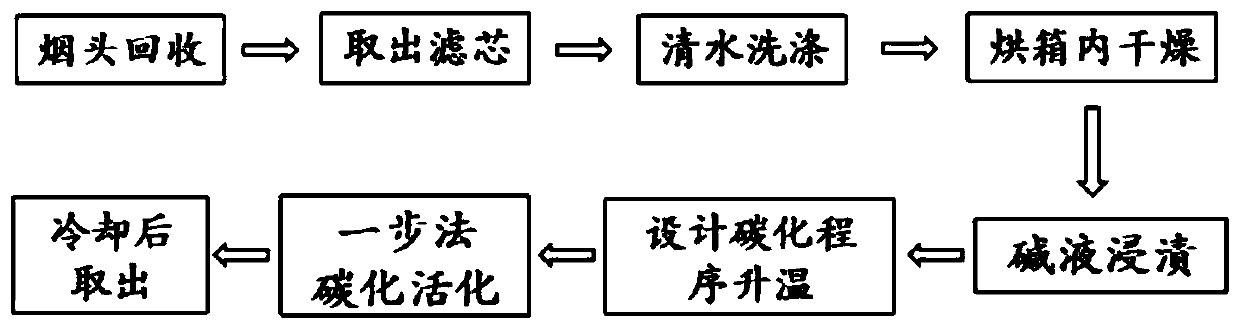

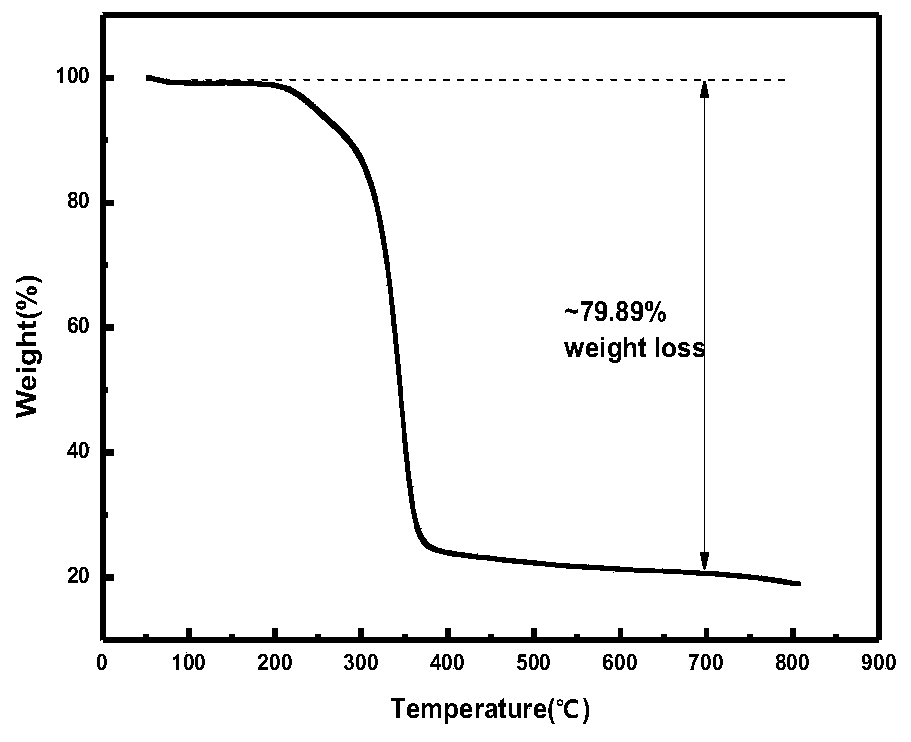

[0033] A KOH solution with a concentration of 6M / L was prepared for use. Collect waste cigarette butts, the diagram is attached figure 1 . Strip the filamentary filter element of the discarded cigarette butt, wash it several times to basically remove impurities, and then fully dry it for later use. The thermal weight loss curve of the test filter element under nitrogen atmosphere is attached image 3 , it is known that the temperature range of rapid carbonization of materials is in the range of 200-400 °C. The filter element is soaked in alkaline solution for 10 minutes, then placed in an oven at 80°C to fully dry, then moved into a tube furnace with a nitrogen atmosphere, and set the temperature to rise rapidly (10°C / min) in the range of 25-200°C and 400-800°C, and 200-200°C The temperature program is to slowly raise the temperature within 400°C (2°C / min), hold at 800°C for 120 minutes for activation, take it out after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com