Analog detection device and analog detection method for laser warning equipment

A technology of laser warning and equipment simulation, which is applied in the direction of measuring devices, optical instrument testing, and machine/structural component testing, etc., which can solve the problems of difficult detection of laser warning equipment response ability, inability to realize automatic, digital and real-time detection, etc. Achieve the effects of improving detection work efficiency, eliminating weather effects, and avoiding wiring complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

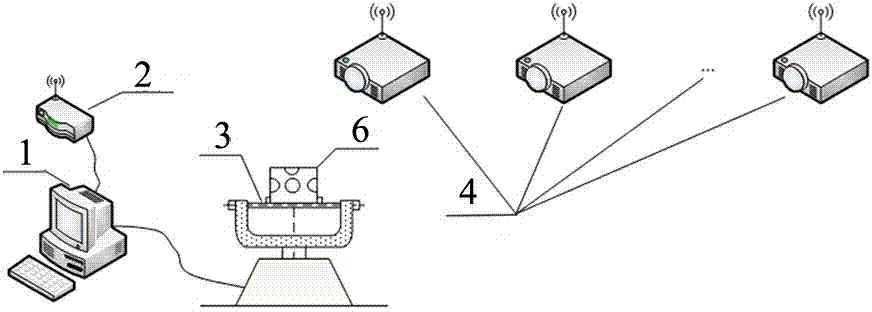

[0029] Such as figure 1 As shown, the laser warning equipment analog detection device of the present invention includes: a multi-wavelength integrated analog laser light source 4, a two-axis servo turntable 3 for installing laser warning equipment, and a control device for controlling the multi-wavelength integrated analog laser light source 4 and the two-axis servo turntable 3. An industrial computer 1 that operates, and a wireless router 2 electrically connected to the industrial computer 1; the wireless router 2 is used to realize wireless communication between the industrial computer 1 and the multi-wavelength integrated analog laser light source 4.

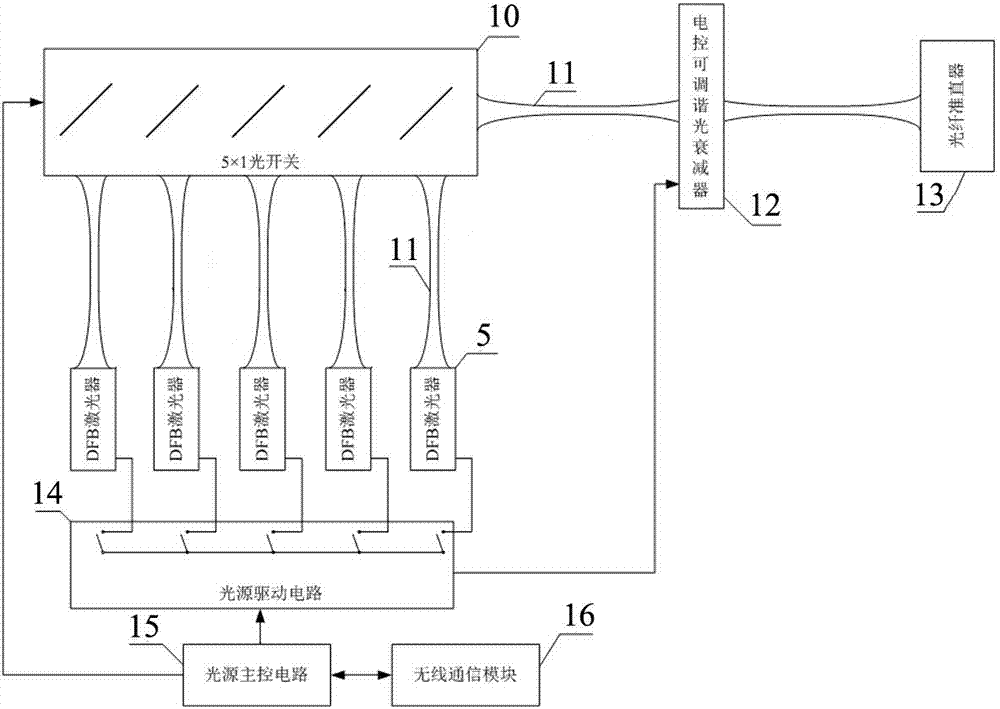

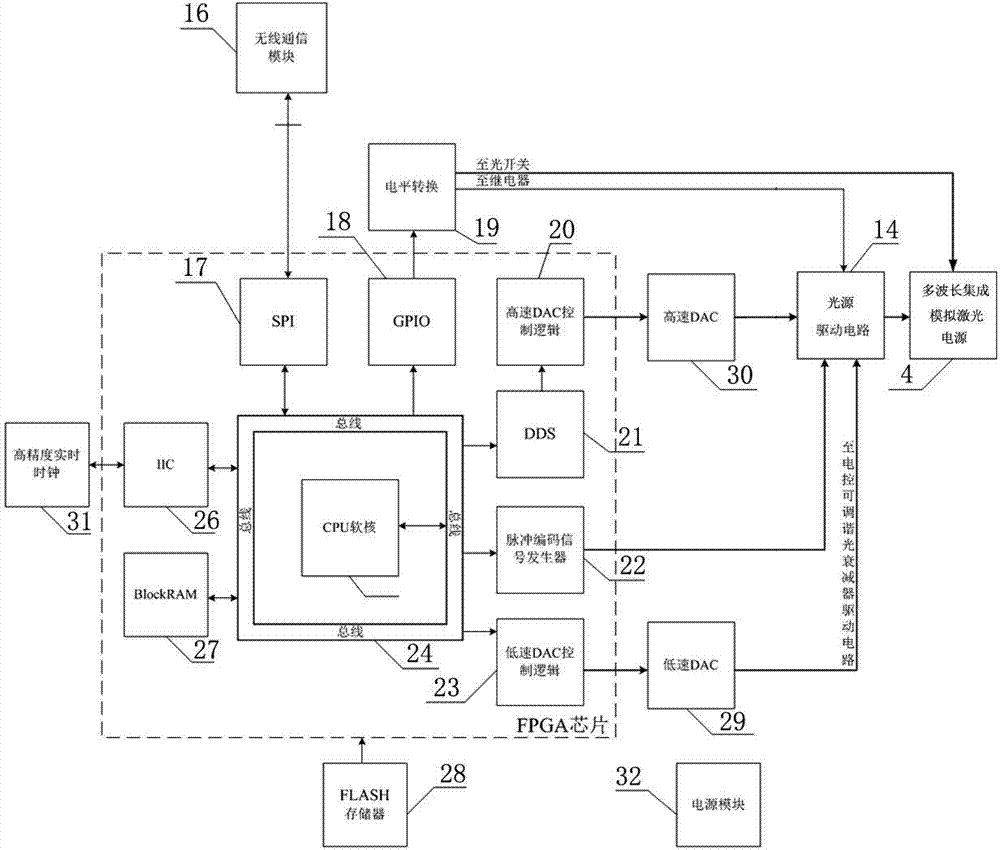

[0030] Such as figure 2 As shown, the multi-wavelength integrated analog laser light source 4 includes: five DFB lasers 5 with emission wavelengths of 860nm, 900nm, 1060nm, 1540nm and 1570nm respectively, and a 5×1 optical switch 10 for switching the light speed of the laser light emitted by the DFB lasers , an electronical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com