Indoor simultaneous determination device and method of piping critical hydraulic gradient and particle wastage rate

A critical hydraulic gradient and particle loss technology, applied in soil material testing, material inspection products, etc., can solve the problems of inability to obtain piping, and the particle loss rate of soil that has not yet formed mature piping, so as to save measurement costs, improve preparation, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

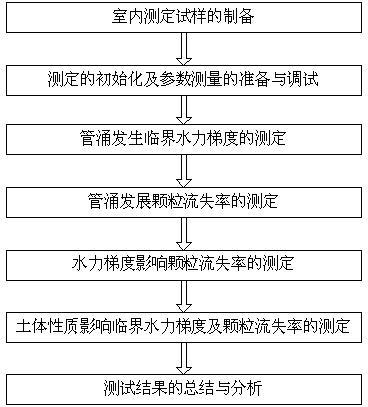

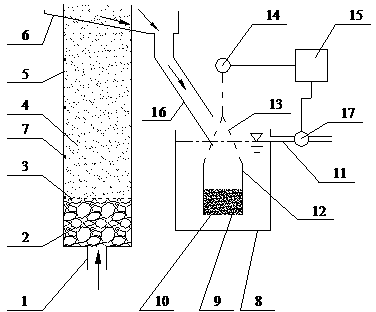

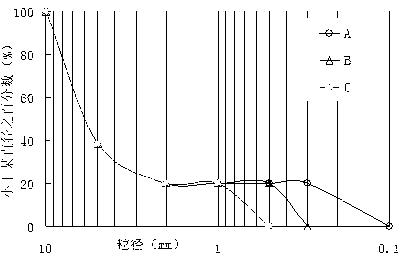

[0046] figure 1 is a flowchart of the method involved in the present invention, figure 2 It is a structural diagram of the device involved in the present invention, image 3 is the soil gradation curve diagram of the sample in the running process of the present invention, Figure 4 is the parameter index data of the sample in the running process of the present invention, Figure 5 It is a graph of the relationship between the critical hydraulic gradient and particle composition and initial porosity during the operation of the present invention, Image 6 It is a graph of the relationship between particle loss law and particle A composition and initial porosity during the operation of the present invention, Figure 7 It is a graph of the relationship between particle loss law and particle B composition and initial porosity during the operation of the present invention, Figure 8 It is a graph showing the relationship between particle loss law and particle C composition and...

Embodiment 2

[0083] The difference between this embodiment and embodiment 1 is only:

[0084]The test device provided in this embodiment includes a model cylinder for accommodating samples, a sand and water collection device, a downstream water collection tank, and a collection and measurement system for gushing soil particles. The model cylinder is placed vertically, with a cylinder height of 50 cm and a diameter of 14 cm; the water inlet at the bottom of the model cylinder provides the upstream seepage drive water head; A sand-separating water-permeable board is installed between the buffer zone and the sample, and the sample is installed on the sand-separating water-permeable board. The height of the sample is 40cm, and the top surface of the sample is flush with the top of the model tube; the side of the model tube is set every 5cm. The pore water pressure sensor is used to measure the change of pore water pressure at different positions in the sample; the pore water pressure sensor is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com