Counter-potential zero-crossing detection circuit and counter-potential zero-crossing detection method for brushless direct-current motor

A technology of zero-crossing detection circuit and brushed DC motor, which is applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., and can solve problems such as failure to ensure normal operation of the motor, low voltage amplitude, and damage to the zero-crossing detection circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

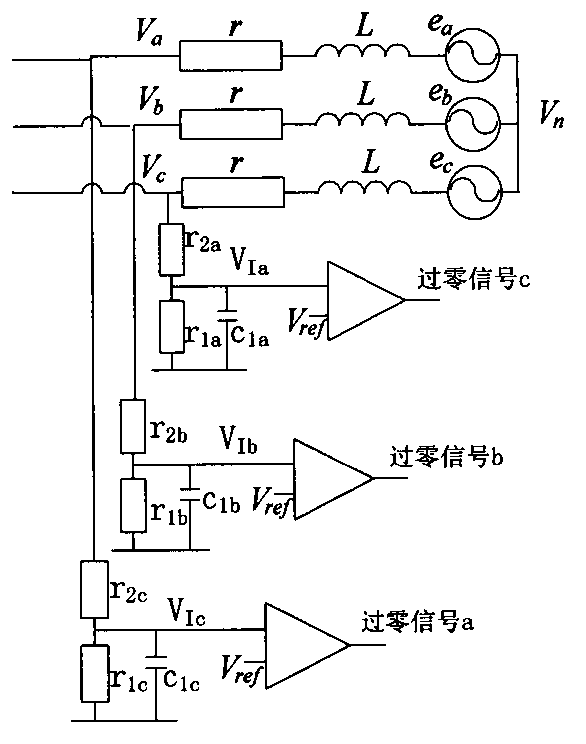

[0071] like Figure 5 As shown, the present invention proposes an improved back EMF zero-crossing detection circuit and method. The reference motor speed is programmed by software and the DSP outputs a square wave signal DSP_EMF_CONTROL with an adjustable duty cycle. The duty cycle of the DSP_EMF_CONTROL signal is proportional to the speed. The duty ratio of the control signal is linearly adjusted, and the signal is used as an input control signal of the improved back EMF zero-crossing detection circuit. When the motor speed is low and the duty cycle of the DSP_EMF_CONTROL control signal is less than 50%, the back EMF is obtained in the state of H_PWM_OFF-L_ON. At this time, the back EMF zero-crossing detection signal can be obtained by directly comparing the sampling signal with 0.

[0072] When the speed increases, the duty cycle of the DSP_EMF_CONTROL control signal also increases. When the duty cycle is greater than 50%, the back EMF is obtained in the state of H_PWM_ON-L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com