High-power inductance testing device, main circuit thereof and testing method thereof

A test device and high-power technology, applied in the direction of measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problems of high cost, large volume, and large space occupied by high-power power inductors, and achieve portability, The effect of simple circuit structure and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

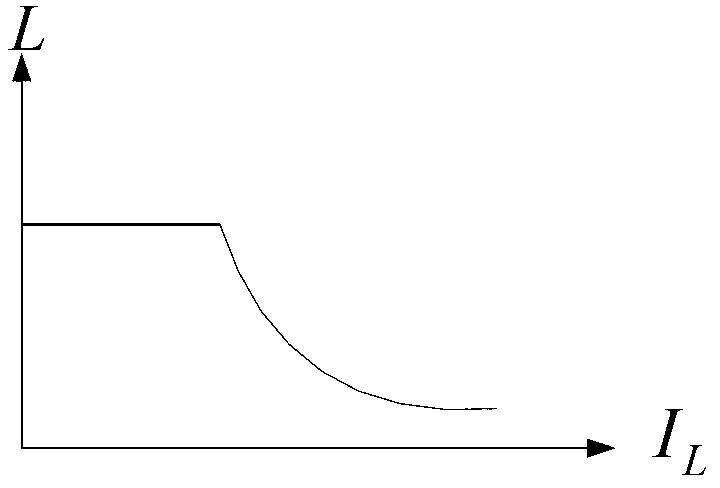

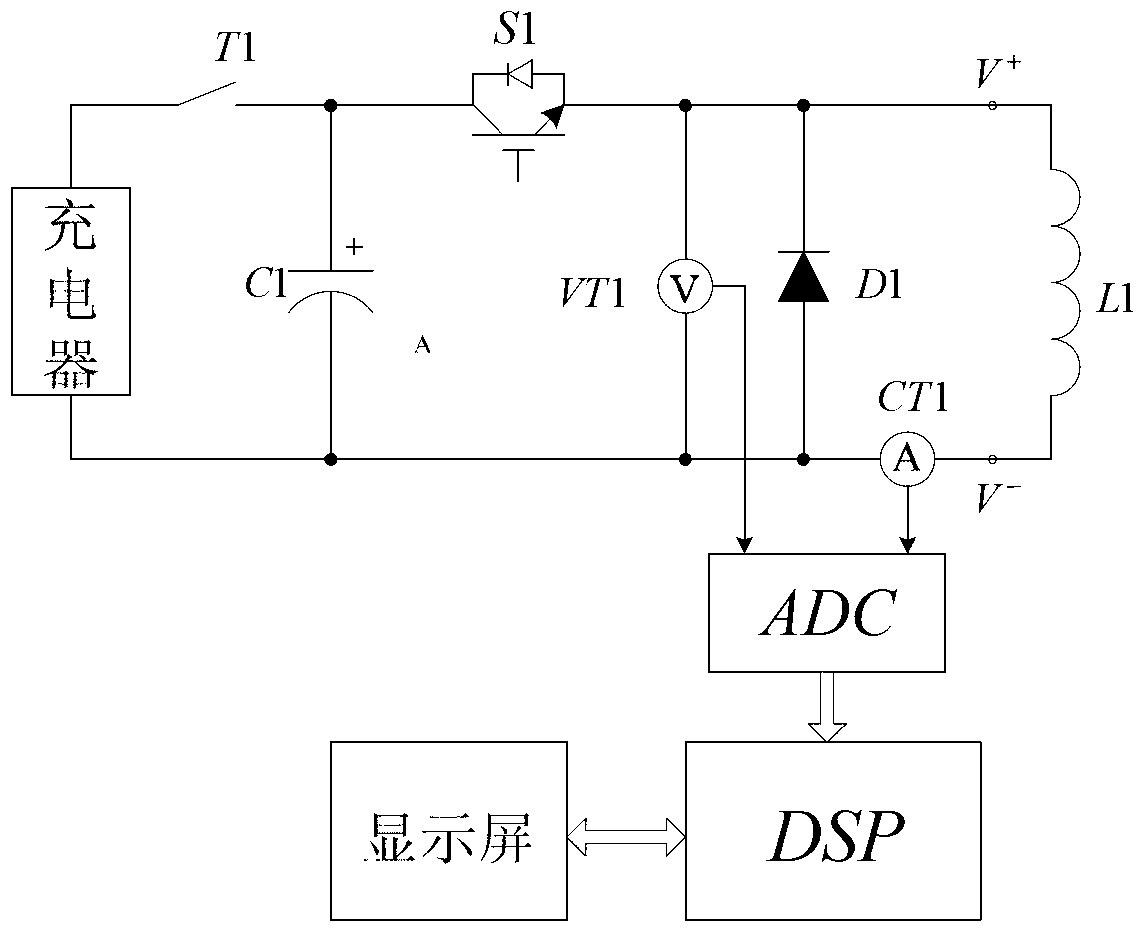

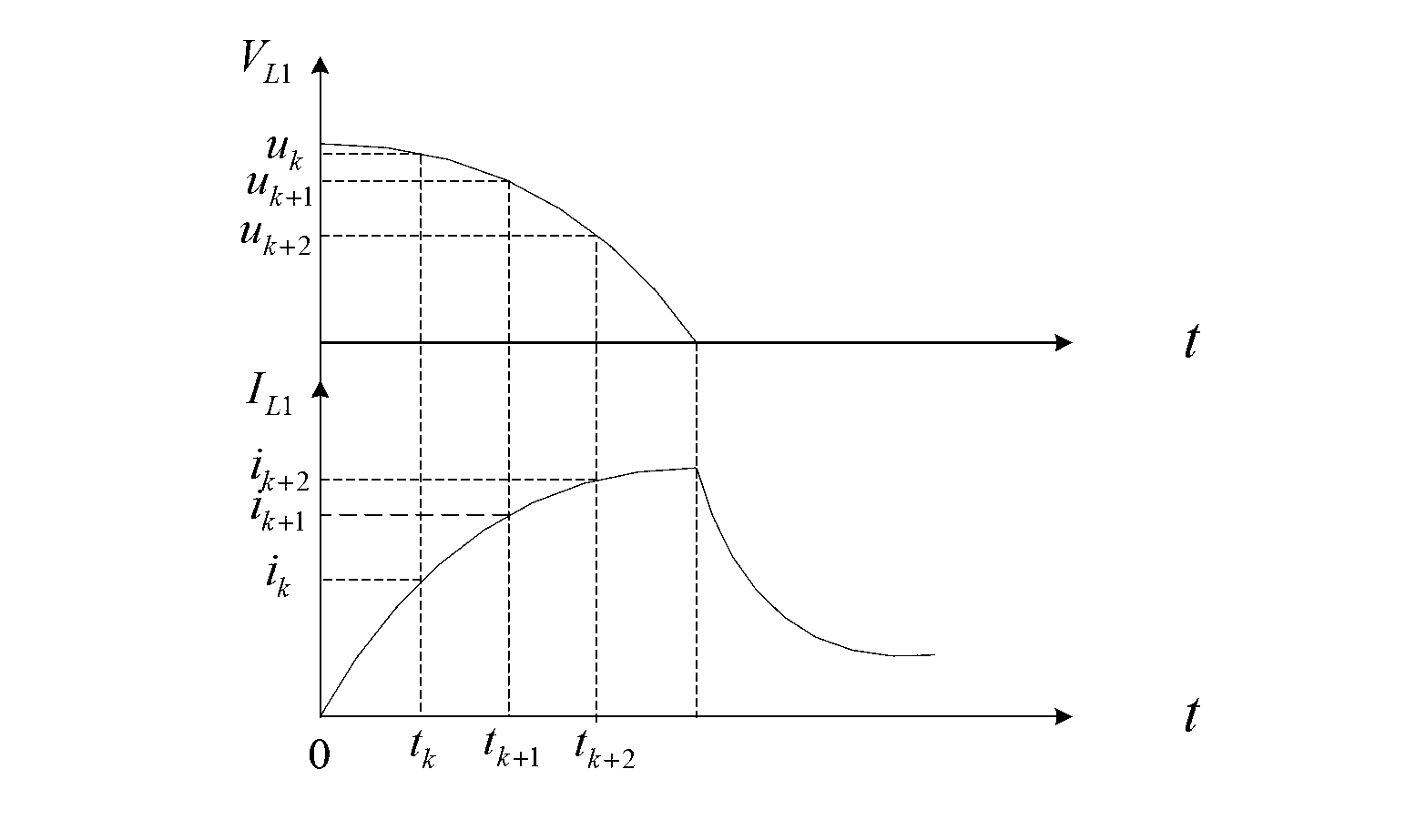

[0021] For inductive equipment, an iron core is usually inserted into the inductance coil to increase the magnetic permeability. The relationship between magnetic permeability, magnetic field strength and magnetic induction is: . When the magnetic induction intensity H is small, the magnetic induction intensity B and the magnetic field intensity are approximately linear, and the magnetic permeability μ is almost unchanged. However, with the further increase of the applied magnetic field intensity, the magnetic induction intensity does not continue to increase linearly, but has a nonlinear relationship with the magnetic field intensity, and finally tends to be saturated and stable at a certain value, at which time the magnetic permeability of the core decreases rapidly. Calculated from the inductance formula It can be seen that the inductance and permeability, the number of turns squared N 2 It is proportional to the cross-sectional area A and inversely proportional to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com