Novel power module

A power module, a new type of technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of great differences in electrical characteristics and reliability of power modules, so as to avoid characteristic differences, improve power density, The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

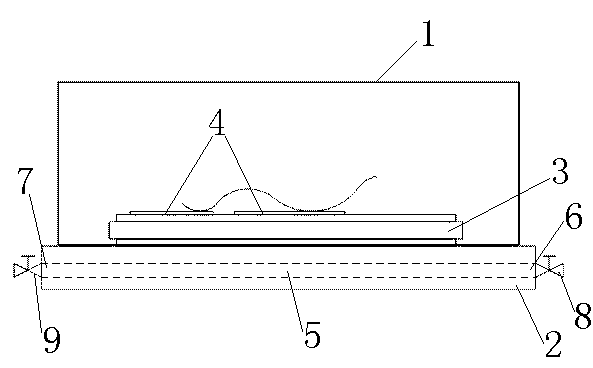

[0021] Embodiment 1, with reference to attached figure 1 , 2 .

[0022] Such as figure 1 As shown, the IGBT power module or MOSFET power module of the present invention includes a housing 1, a substrate 2, a substrate 3, and a chip 4, the substrate 2 is connected to a radiator, the chip 4 and the substrate 3 are connected by soldering, and the substrate 3 and the substrate 4 The housing 1 is covered on the substrate 4 through a fixed connection by soldering. The inside of the substrate 4 has a cooling channel 5 and a cooling medium inlet 6 and a cooling medium outlet 7 connected to the cooling channel 5. The cooling medium inlet 6, the cooling medium outlet 7, and the cooling channel 5 constitute a cooling medium flow circuit; the cooling medium inlet 6 and cooling medium outlet 7 are provided with an inlet valve 8 and an outlet valve 9 respectively.

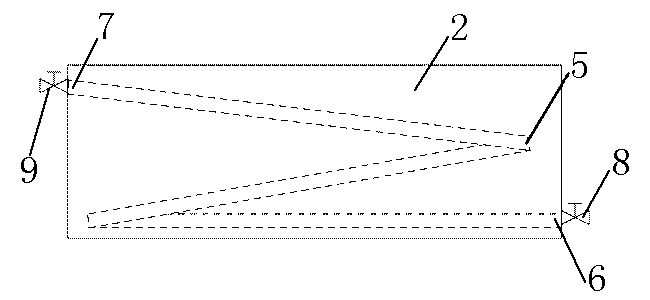

[0023] Such as figure 2 As shown, the heat dissipation channels 5 are distributed inside the substrate 4 in a Z shape. ...

Embodiment 2

[0026] Embodiment 2, with reference to attached figure 1 , 3 .

[0027] Such as figure 1 As shown, the IGBT power module or MOSFET power module of the present invention includes a housing 1, a substrate 2, a substrate 3, and a chip 4, the substrate 2 is connected to a radiator, the chip 4 and the substrate 3 are connected by soldering, and the substrate 3 and the substrate 4 The housing 1 is covered on the substrate 4 through a fixed connection by soldering. The inside of the substrate 4 has a cooling channel 5 and a cooling medium inlet 6 and a cooling medium outlet 7 connected to the cooling channel 5. The cooling medium inlet 6, the cooling medium outlet 7, and the cooling channel 5 constitute a cooling medium flow circuit; the cooling medium inlet 6 and cooling medium outlet 7 are provided with an inlet valve 8 and an outlet valve 9 respectively.

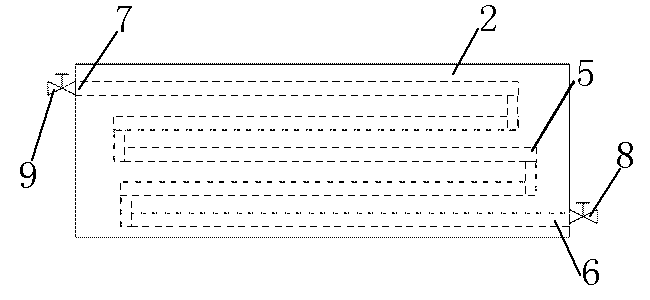

[0028] Such as image 3 As shown, the heat dissipation channels 5 are distributed inside the substrate 4 in an S shape. ...

Embodiment 3

[0031] Embodiment 3, with reference to attached figure 1 , 4 .

[0032] Such as figure 1 As shown, the IGBT power module or MOSFET power module of the present invention includes a housing 1, a substrate 2, a substrate 3, and a chip 4, the substrate 2 is connected to a radiator, the chip 4 and the substrate 3 are connected by soldering, and the substrate 3 and the substrate 4 The housing 1 is covered on the substrate 4 through a fixed connection by soldering. The inside of the substrate 4 has a cooling channel 5 and a cooling medium inlet 6 and a cooling medium outlet 7 connected to the cooling channel 5. The cooling medium inlet 6, the cooling medium outlet 7, and the cooling channel 5 constitute a cooling medium flow circuit; the cooling medium inlet 6 and cooling medium outlet 7 are provided with an inlet valve 8 and an outlet valve 9 respectively.

[0033] Such as Figure 4 As shown, the heat dissipation channels 5 are distributed inside the substrate 4 in a wave shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com