Hybrid-clamped three-electric-level three-phase four-wired photovoltaic system based on 3D-SPWM (three-dimensional sinusoidal pulse width modulation)

A 3D-SPWM, three-phase four-wire system technology, applied in the direction of photovoltaic power generation, electrical components, single-net parallel feeding arrangement, etc., can solve the problems of three-phase grid-connected current imbalance, poor flexibility, difficulties, etc., to reduce System neutral current, ensure height balance, ensure balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

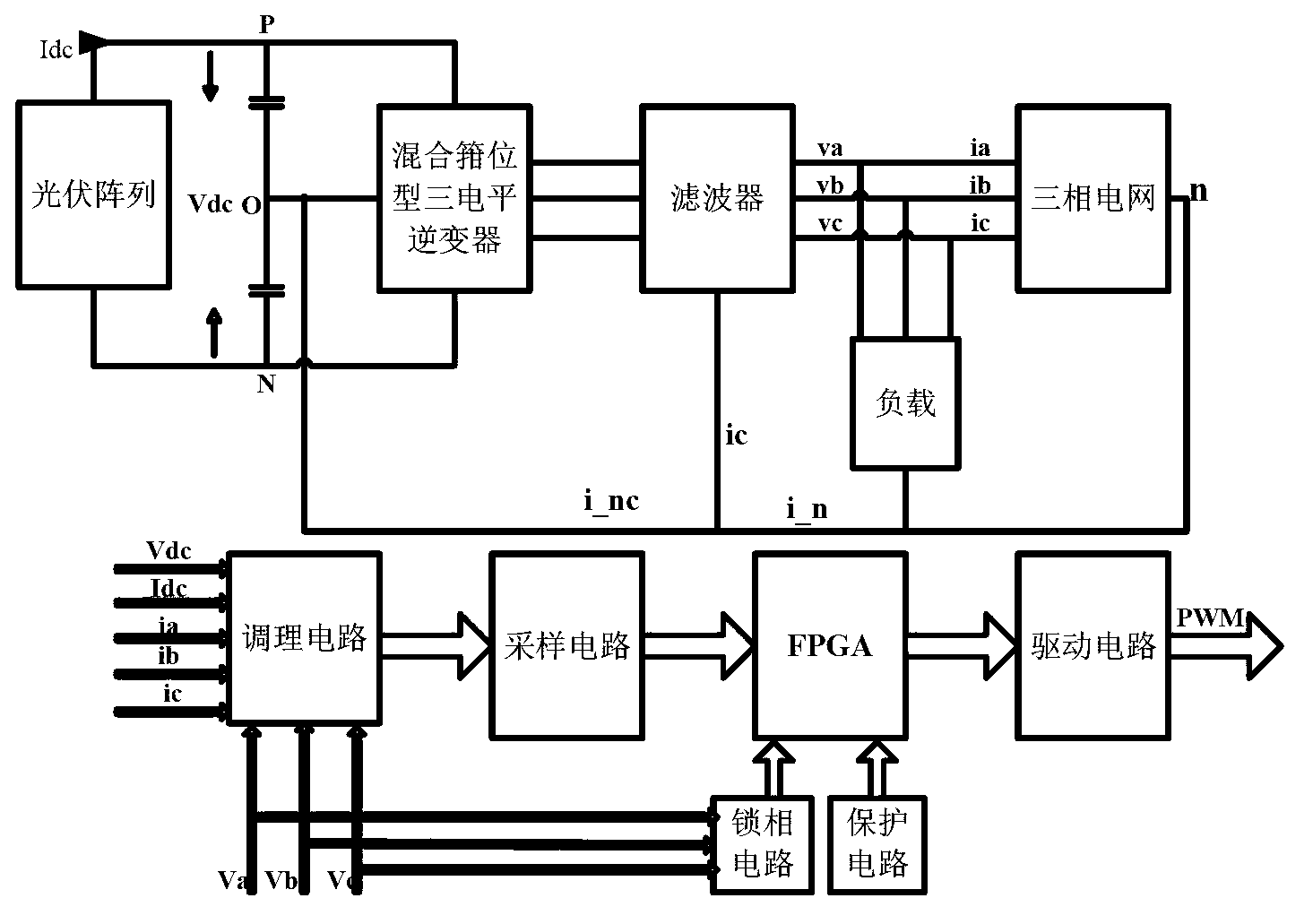

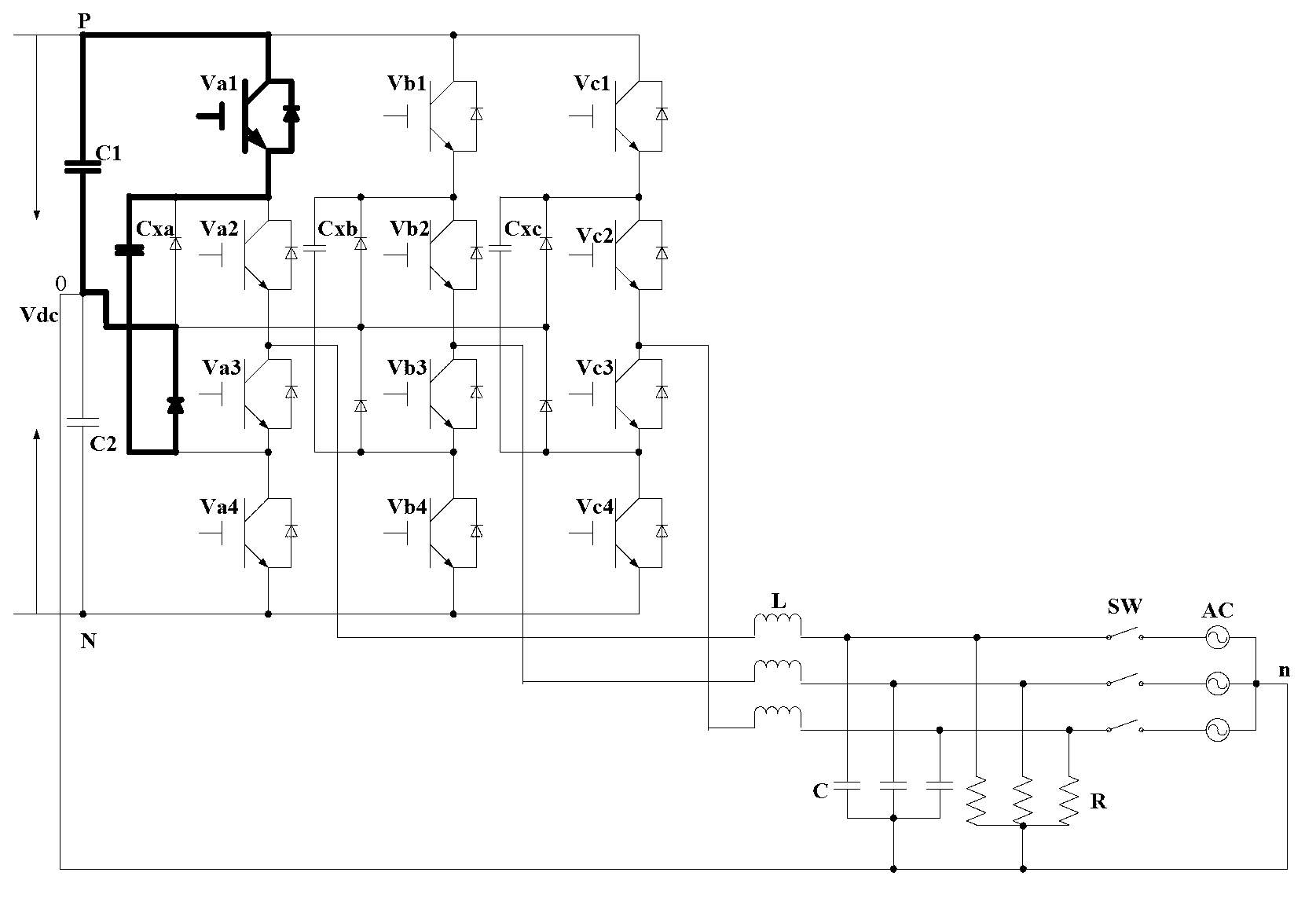

[0031] figure 1 It is a system structure diagram, the main circuit is a hybrid clamp type three-level inverter, the midpoint of the DC side is directly connected to the photovoltaic cell array, and the filter is an LC filter circuit. The output terminal of the system is connected to the load and the three-phase grid, and the common terminal n of the three-phase grid is connected to the common terminal of the load, the common terminal of the filter capacitor and the midpoint of the DC side.

[0032] For the three-phase four-wire structure, if the 2D-SVPWM control method is adopted, since the final modulation waveform contains a large number of third harmonics, it will cause the output current i of the common terminal of the filter capacitor C If it is too large (more than 10A), if the load is unbalanced during independent operation, then i_n will be lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com