Crude oil electric dehydration high voltage power supply device

A high-voltage power supply and electric dehydration technology, which is applied in the direction of electricity use/magnetic dehydration/demulsification, etc., can solve the problems of increasing the capacity demand of high-voltage power supply devices in high-voltage dehydration electric field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

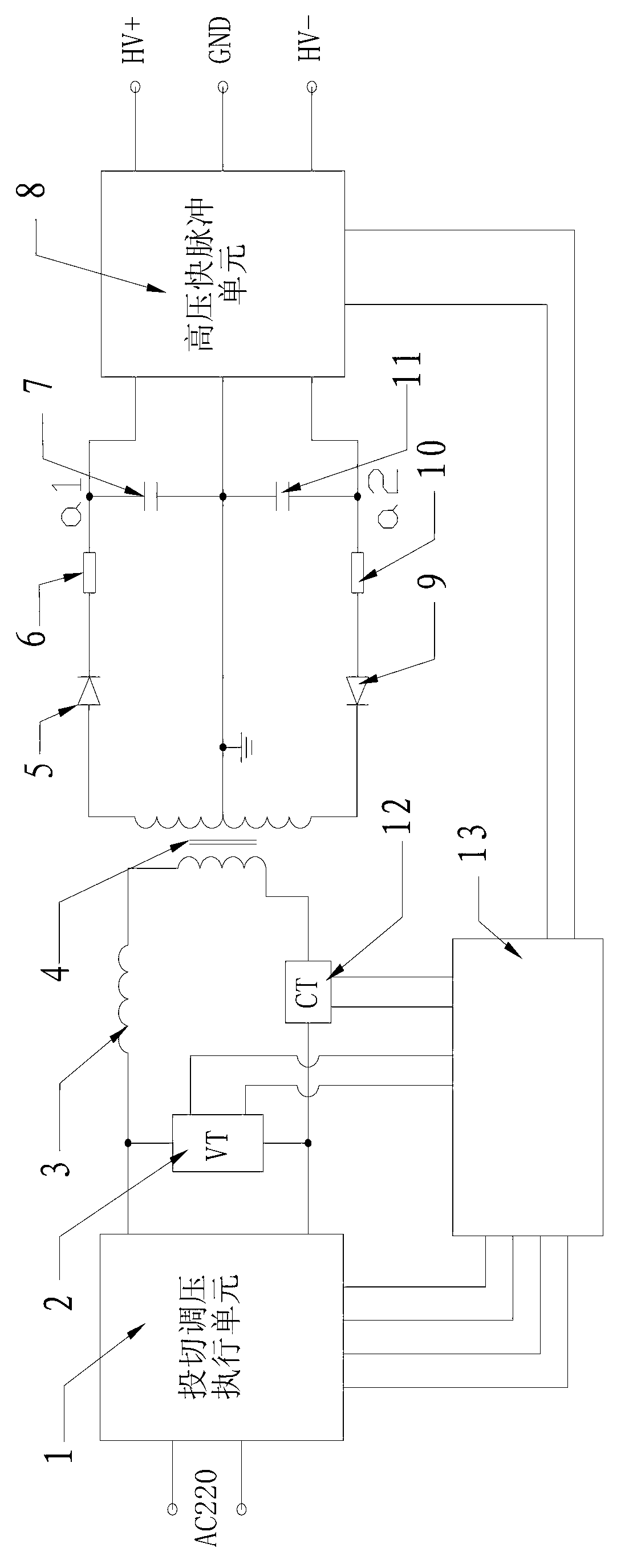

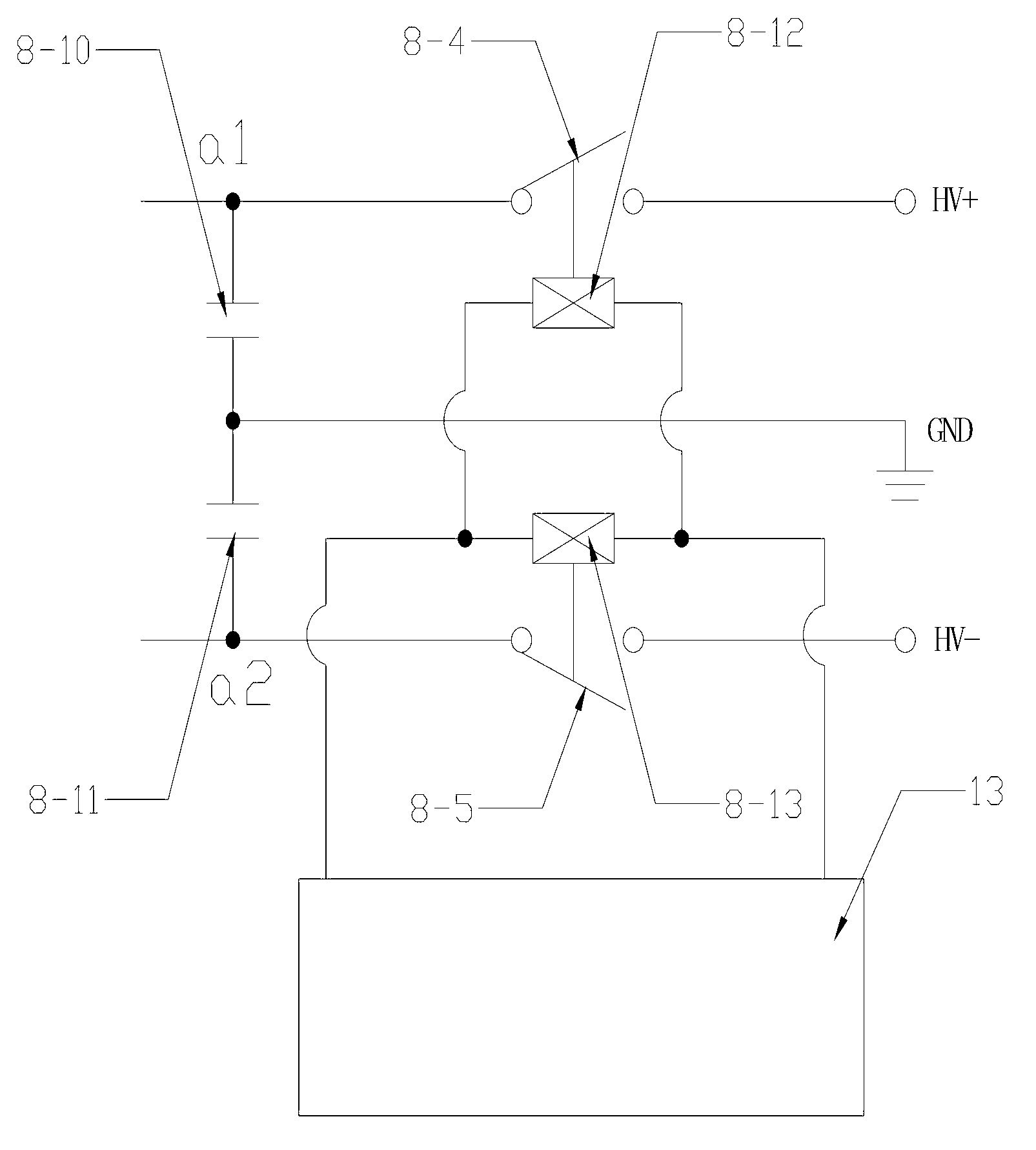

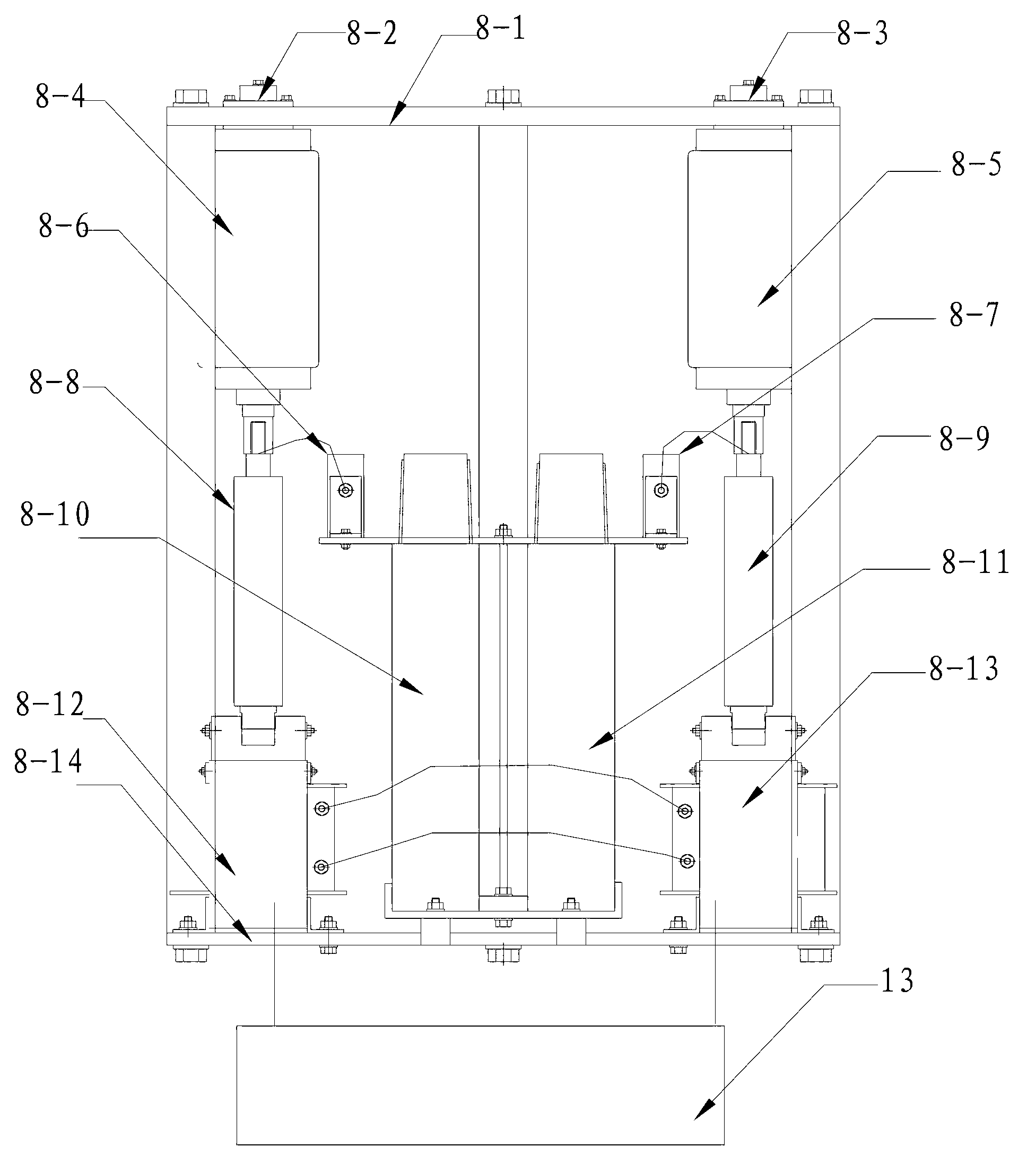

[0016] Specific implementation mode 1. Combination figure 1 Specifically explain this embodiment, the crude oil electric dehydration high-voltage power supply device described in this embodiment includes a switching and voltage regulation execution unit 1, a voltage sensor 2, a current-limiting reactor 3, a high-voltage transformer 4, a first high-voltage silicon stack 5, The first current limiting resistor 6, the first high voltage capacitor 7, the high voltage fast pulse unit 8, the second high voltage silicon stack 9, the second current limiting resistor 10, the second high voltage capacitor 11, the current sensor 12 and the microcomputer control unit 13,

[0017] A voltage output end of the switching and voltage regulation execution unit 1 is connected to one end of a current-limiting reactor 3, and the other end of the current-limiting reactor 3 is connected to one end of the primary coil of the high-voltage transformer 4, and the high-voltage transformer 4 The other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com