Inertia type piezoelectric linear motor

A linear motor and inertial technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of reducing the output force of the driver and unable to fully utilize the piezoelectric material Drive performance, complexity and other issues, to achieve the effect of large output force, simple structure and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

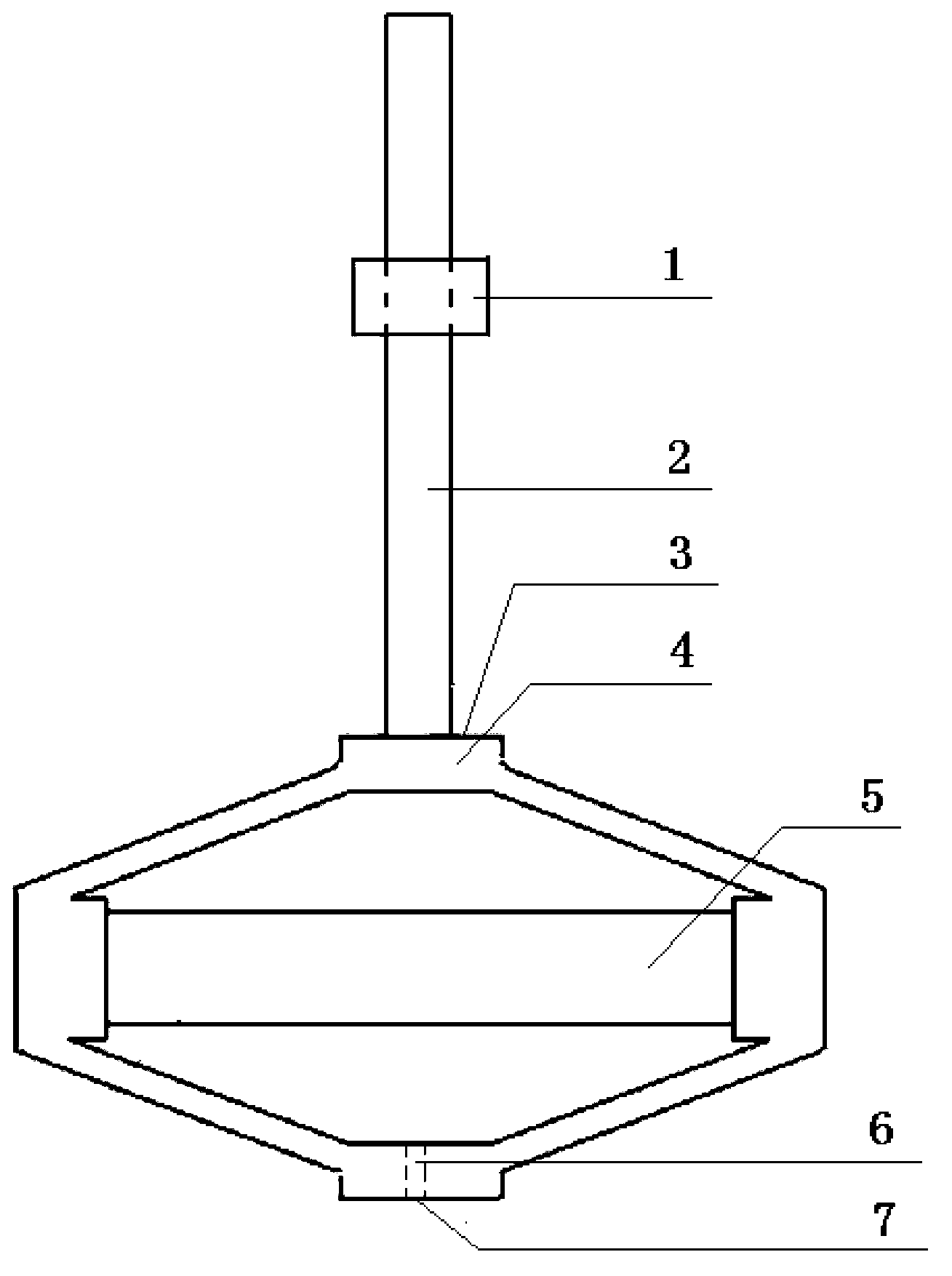

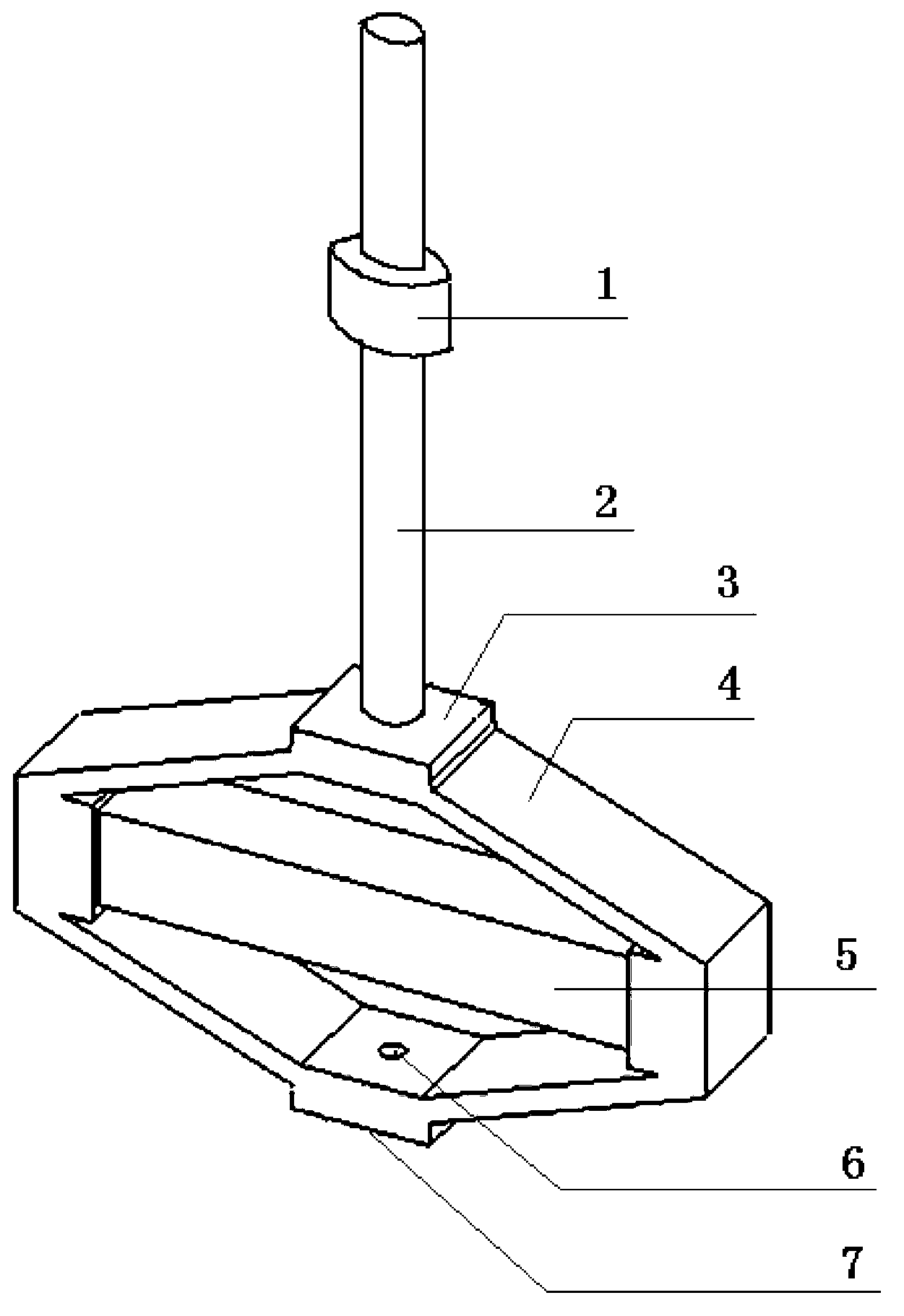

[0020] Such as figure 1 with 2 As shown, the mover 1, the stator shaft 2 and the displacement amplifying mechanism 4 in the inertial piezoelectric linear motor of the present invention can be made of steel, copper alloy, aluminum alloy and other related metal materials.

[0021] An annular mover 1 with a certain mass is tightly sleeved on the cylindrical stator shaft 2 with a certain pre-pressure, and the mover 1 can realize linear motion on the stator shaft 2 by using friction force and inertial force. A cylindrical end surface of the stator shaft 2 is directly bonded to the translation surface 3 of the displacement amplification mechanism 4, and ensures that the axial direction of the stator shaft 2 is perpendicular to the translation surface 3, so that the output displacement of the displacement amplification mechanism 4 is transmitted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com