Method for producing rice powder and rice powder obtained thereby

A manufacturing method and technology of rice noodles, applied in the direction of food preparation, application, food science, etc., to achieve the effect of reducing the load current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069]

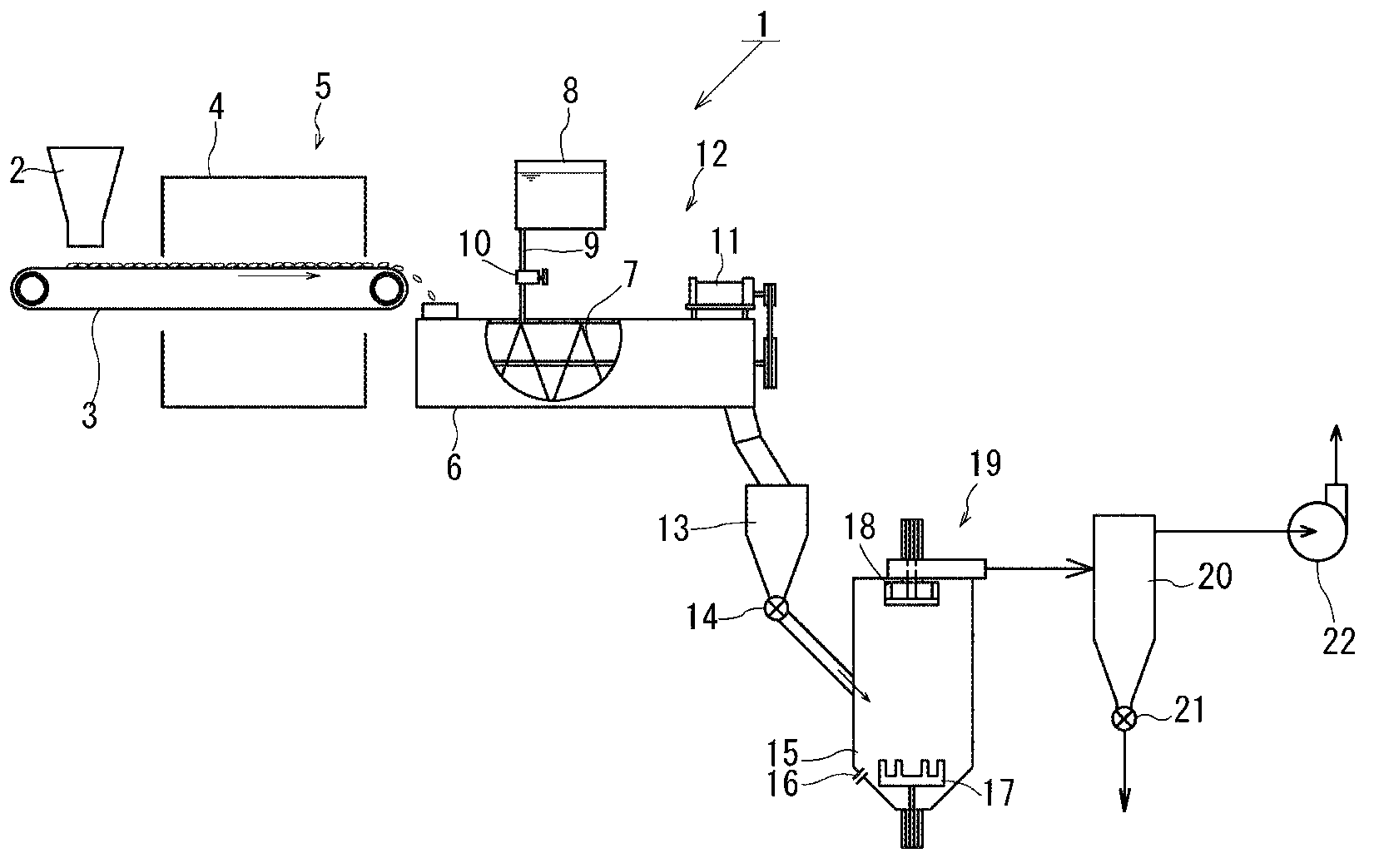

[0070] Japonica rice with a water content of 15% to 16% (w.b.%) is used as raw material. Then, the non-japonica rice is put into the raw material tank 2 of the pretreatment unit 5, and the non-japonica rice supplied from the raw material tank 2 is spread on the endless belt conveyor 3 in a sheet form with a thickness of about 5 mm to 20 mm for conveyance. In the heating device 4 , hot air at 40° C. is supplied for 10 to 40 minutes to dry the japonica rice until the moisture content of the japonica rice reaches about 11% to 13% (w.b.%). Thereby, generate many tortoise-like or fish-scale fine fissures ( Figure 2 ~ Figure 4 ).

[0071]

[0072] The rice grains with fine cracks formed on the surface are carried out from the heating device 4 and supplied to the water filling drum 6 of the water filling unit 12 . The water adding part 12 controls the water adding amount through the valve 10 . Control the amount of water added so that the water content of the entire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com