Titanium dioxide doped with fluorine and its preparation method

A technology of titanium dioxide and nitrogen oxides, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, secondary batteries, etc., to achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

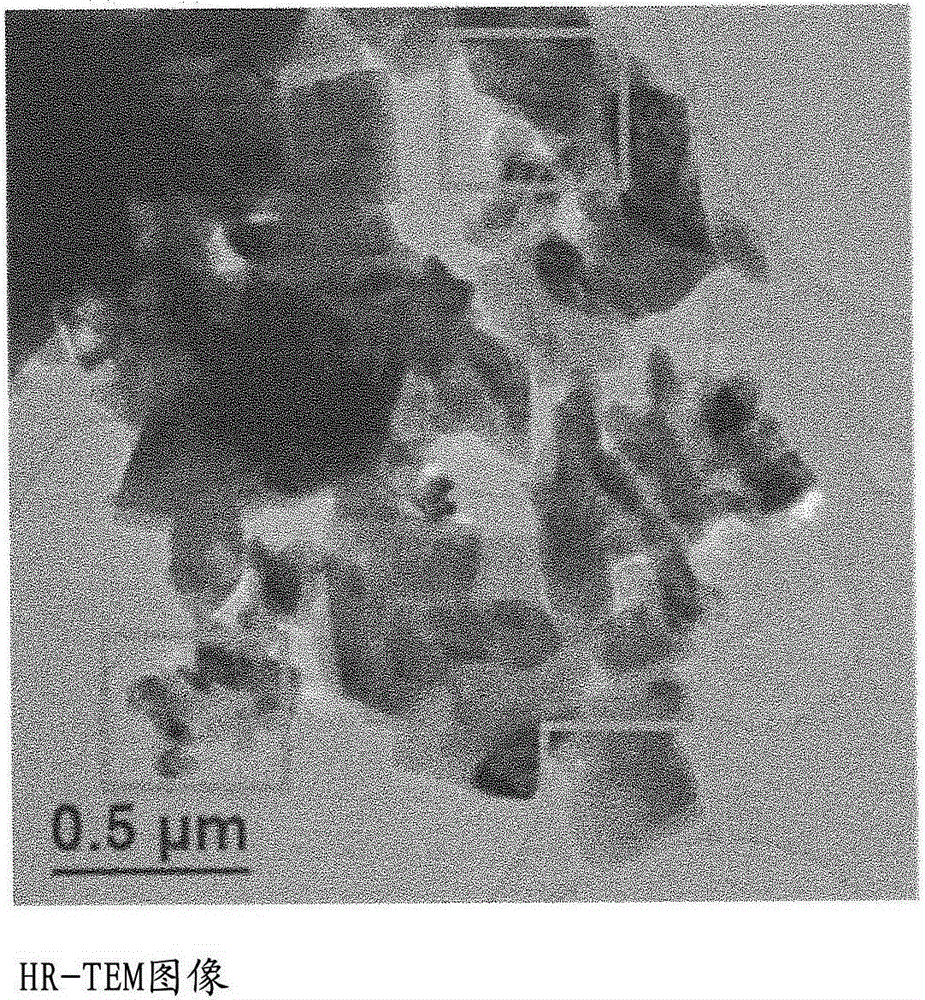

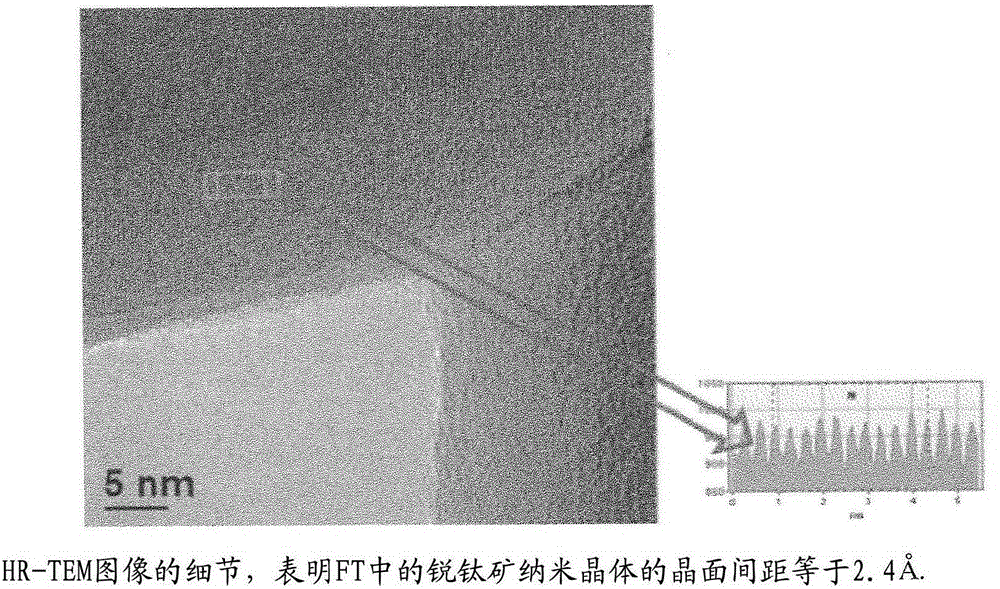

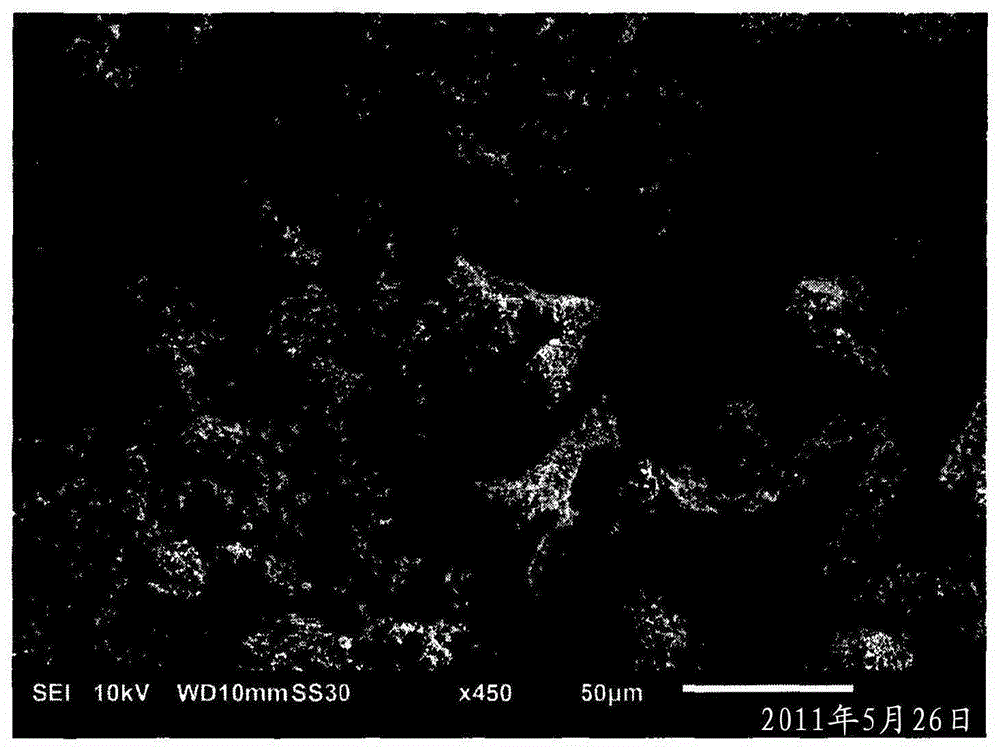

[0087] Example (a): Fluorine-doped TiO 2 (FT) Preparation

[0088] Mix 7 liters of water, 3kg of NH 4 HF 2 Salt and 1341 g of ilmenite sand sieved to a particle size of less than 200 microns were placed in a stirred reactor having a volume of about 10 liters. The mixture was then boiled at atmospheric pressure and kept boiling for about 1 hour. After this step of reacting with the ore, 4 liters of solution were discharged through a valve in the bottom of the reactor and then filtered. 1.5 liters of a 30% concentrated ammonia solution was added to the thermostat-controlled solution containing titanium fluoride and iron fluoride salts at 70° C. thus filtered to raise its pH to 7.3. The white precipitate was isolated by filtration and an additional 2 liters of 30% concentrated ammonia solution in water was added to the filtrate to obtain a pH of about 9.5. The white precipitate was isolated by filtration and subjected to a subsequent pyrohydrolysis step. About 30 g of this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com