Composite coating, preparation method and application thereof, composite lithium negative electrode and preparation method of negative electrode

A technology of composite coating and lithium negative electrode, which is applied in the fields of preparation, composite coating, composite lithium negative electrode and preparation, can solve the problems of loose contact between electrolyte membrane and lithium metal surface, increase of battery quality, increase of interface impedance, etc., and achieve excellent Effects of ionic conductivity, high mechanical strength, and excellent deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of composite coating of the present invention specifically comprises the following steps:

[0031] Step S1, after ball milling the cubic phase LLXO powder, according to the ratio of 1g: 0.1ml ~ 1ml, the ball milled cubic phase LLXO powder and both -C=C- and -Si-O-CH 3 -The polymer with functional group is added to the organic solvent, heated at 100°C-150°C after ultrasonication, reacted for 1h-5h under stirring conditions, centrifuged, washed several times, and dried to obtain LLXO-Si powder. The choice of organic solvent is to be able to dissolve and disperse the above-mentioned substances and not participate in the reaction. The minimum amount of solvent is to ensure that LLXO powder and polymer can be fully dispersed.

[0032] In this step, the LLXO powder is an inorganic solid electrolyte selected from Li 3x La 2 / 3-x TiO 3 , Li 5 La 3 m 2 o 12 , Li 6 ALa 2 m 2 o 12 , Li 7 La 3 Q 2 o 12 , (C=Zr, Sn) or Li 7 La 3 Ta 2 o 13...

Embodiment 1

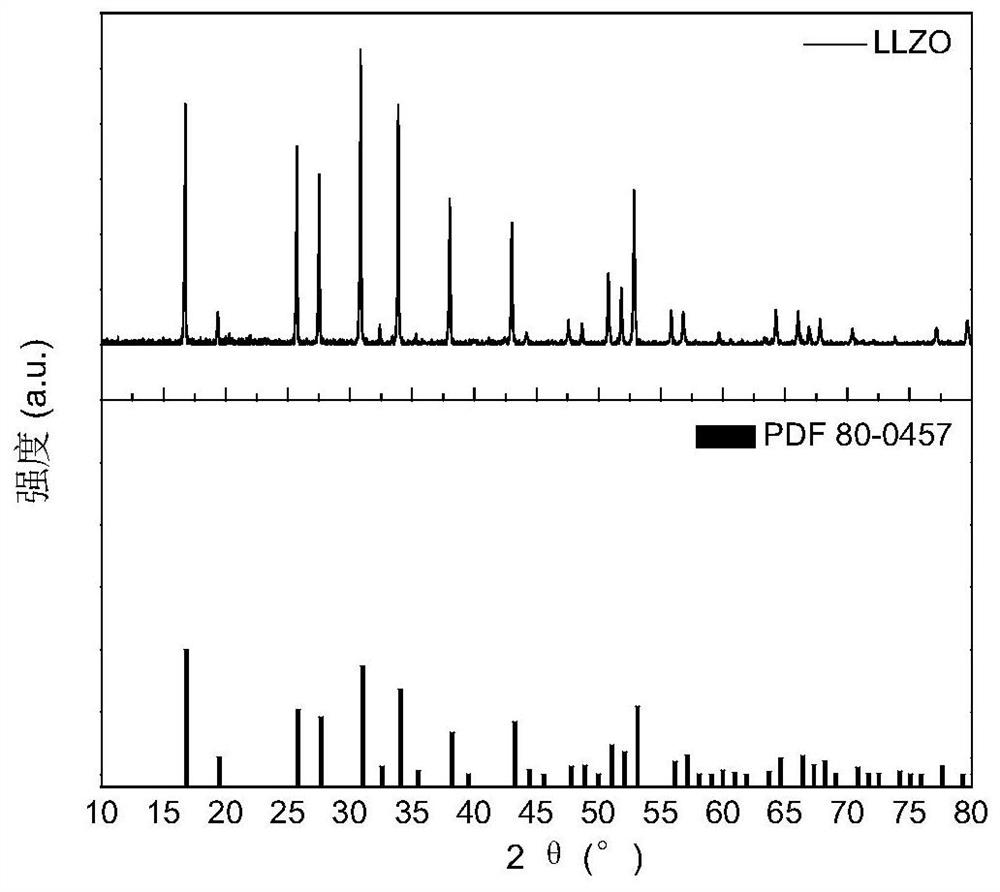

[0047] A composite coating for the negative electrode of a lithium battery, prepared by the following preparation method: 0.5309g lithium nitrate, 1.299g lanthanum nitrate, 0.09g aluminum nitrate, 0.8544g zirconium acetylacetonate, 0.0675g niobium chloride, 1.4976g lemon Add acid, 0.48413g ethylene glycol, into 60ml deionized water and 20ml ethanol, stir at 80°C for 12h until the solution is clear and viscous, put it into an oven, set the temperature at 90°C, and hold for 12h. Adjust the setting temperature of the oven to 250°C, and the holding time to 3h. Put it into a tube furnace after grinding, the heating rate is 10°C / min, the target temperature is 850°C, and the holding time is 2h to obtain LLXO powder. The structural formula of the LLXO powder is Li 6.03 La 3 Zr 1.75 Nb 0.25 Al 0.24 o 12 . Carry out X-ray diffraction (XRD) detection to this powder, detection result sees figure 1 .

[0048] figure 1 It is the XRD pattern of cubic phase LLXO powder and JCPDS (#80...

Embodiment 2

[0061] A composite coating for the negative electrode of a lithium battery, prepared by the following preparation method: 0.5309g lithium nitrate, 1.299g lanthanum nitrate, 0.09g aluminum nitrate, 0.8544g zirconium acetylacetonate, 0.0675g niobium chloride, 1.4976g lemon Add acid, 0.48413g ethylene glycol, into 60ml deionized water and 20ml ethanol, stir at 80°C for 12h until the solution is clear and viscous, put it into an oven, set the temperature at 90°C, and hold for 12h. Adjust the setting temperature of the oven to 250°C, and the holding time to 3h. Put it into a tube furnace after grinding, the heating rate is 10°C / min, the target temperature is 850°C, and the holding time is 2h to obtain LLXO powder. The structural formula of the LLXO powder is Li 6.03 La 3 Zr 1.75 Nb 0.25 Al 0.24 o 12 .

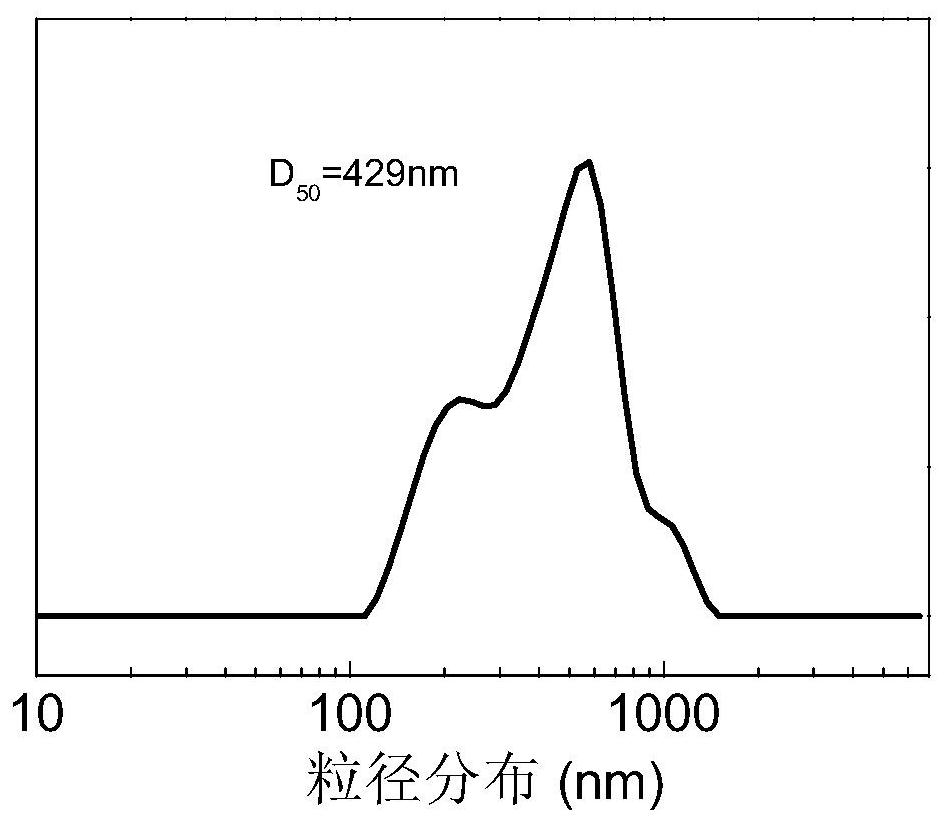

[0062] The prepared LLXO powder was ball milled at a rotational speed of 200r / min for 8 hours, and the direction was changed every 30 minutes. Add 0.6 g of ball-milled cubic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com