Solid-state polymer electrolyte membrane with grid structure, and preparation method thereof

A solid polymer, grid structure technology, used in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of poor electrochemical performance and mechanical properties of solid polymer electrolyte membranes, and improve electrochemical stability. The effect of improving and reducing the deformation of the high elastic amorphous region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

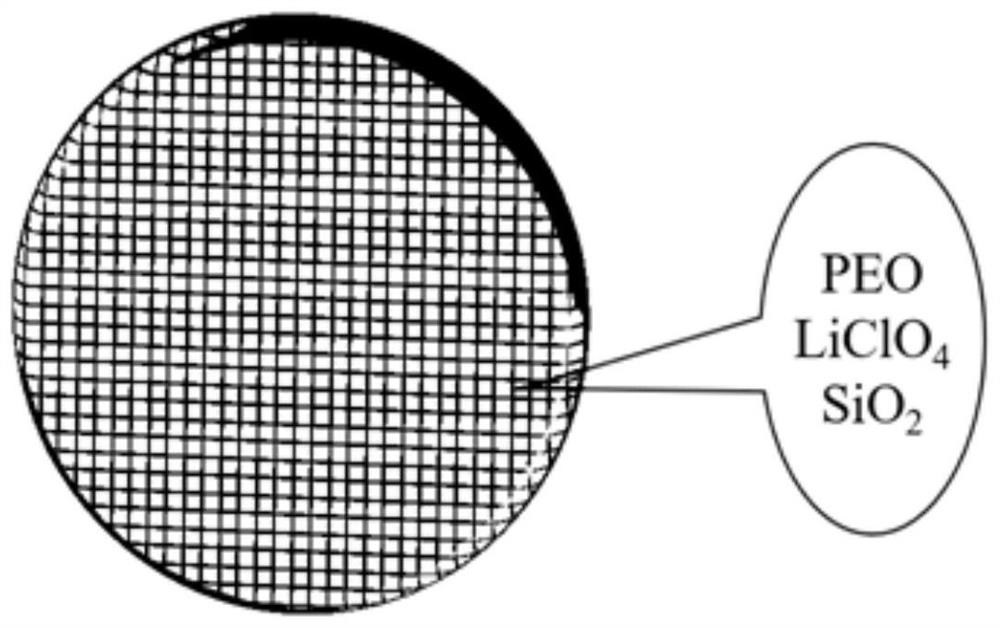

[0042] A preparation method of a lithium-ion battery solid polymer electrolyte membrane with a grid structure, comprising the following steps:

[0043] Raw material preparation: PEO as polymer matrix, LiClO 4 As lithium salt, SiO 2 Nanoparticles (hydrophilic) as inert fillers;

[0044] (1) SiO with an addition amount of 6.85wt% 2 Nanoparticles were added into acetonitrile solvent, magnetically stirred for 0.5h, and then ultrasonically dispersed for 1h to dissolve the SiO 2 Uniformly dispersed in the solvent, followed by PEO and LiClO 4 According to the ratio of the amount of substance, it is n(EO):n(LiClO 4 )=12:1 is dissolved in the acetonitrile solvent, the mass fraction of PEO is 4.7wt%, magnetic stirring 12h, obtains the solid electrolyte precursor namely spinning solution;

[0045] (2) Electrospin the spinning solution obtained in (1) onto the receiver (the receiver is a flat grid structure, and the distance between the grid nodes is 50 mm) under electrostatic high v...

Embodiment 2

[0056] Raw material preparation: PEO as polymer matrix, LiClO 4 As lithium salt, SiO 2 Nanoparticles (hydrophilic) as inert fillers;

[0057] (1) SiO with an addition amount of 6.85wt% 2 Nanoparticles were added into acetonitrile solvent, magnetically stirred for 0.5h, and then ultrasonically dispersed for 1h to dissolve the SiO 2 Uniformly dispersed in the solvent, followed by PEO and LiClO 4 According to the molar ratio of substances, it is nEO:nLiClO 4 =12:1 dissolved in acetonitrile solvent, the mass fraction of PEO is 4.7wt%, magnetically stirred for 12h, to obtain the solid electrolyte precursor that is the spinning solution;

[0058] (2) Electrospin the spinning solution obtained in (1) onto the receiver (the receiver is a flat grid structure, and the distance between the grid nodes is 50 mm) under electrostatic high voltage. The parameters of the equipment are to prepare a solid polymer electrolyte membrane, and vacuum-dry the obtained solid polymer electrolyte me...

Embodiment 3

[0063] A preparation method of a lithium-ion battery solid polymer electrolyte membrane with a grid structure, comprising the following steps:

[0064] Raw material preparation: According to Table 1, select the corresponding inert filler, organic solvent, polymer matrix and lithium salt in sequence;

[0065] (1) Add the hydrophilic inert filler with an addition amount of 8wt% to the organic solvent, disperse the inert filler in the organic solvent by ultrasonic dispersion for 4 hours after magnetic stirring for 2 hours, and then mix the polymer matrix and lithium salt according to the amount of the substance Dissolved in an organic solvent with a ratio of 8:1, the mass fraction of the polymer matrix is 4.7wt%, and magnetically stirred for 18 hours to obtain a solid electrolyte precursor, that is, a spinning solution;

[0066] (2) Electrospin the spinning solution obtained in step (1) onto the receiver under electrostatic high voltage, and prepare a solid polymer electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com