Filter system for built-in containment refueling water storage tank

A refueling water tank and filter technology, which is applied in the fields of filtration and separation, filtration loops, chemical instruments and methods, etc., can solve the problems affecting the heat transfer of the reactor core, the large number of particles and fibers in the filter screen, and the large flow area, etc. Ability to cope with accidents, small footprint, and the effect of low filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

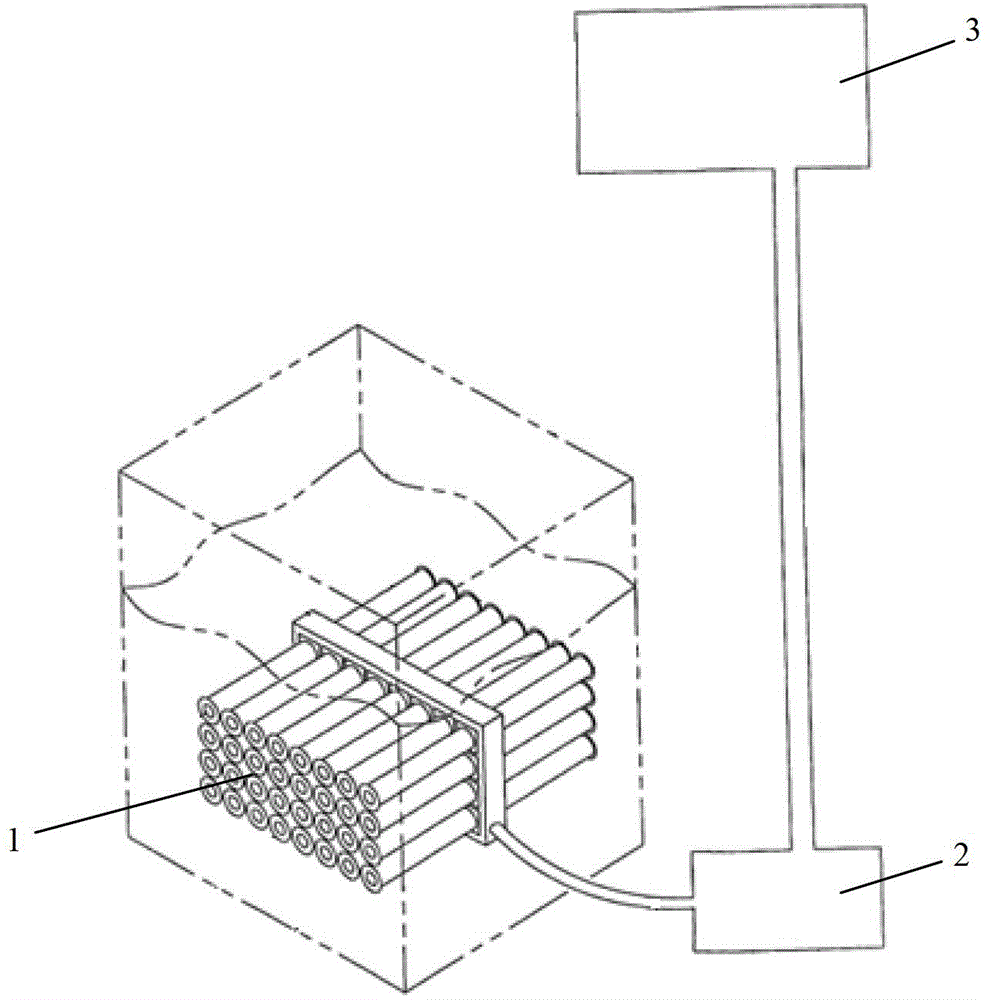

[0019] The present invention changes the traditional filter single-stage filtration into three-stage filtration, and installs a three-stage filter at the built-in refueling water tank (IRWST), intercepting debris under accident conditions, and fine-tuning the water collected by the IRWST. Filtration to ensure that the water entering the containment spray system (CSP) and safety injection system (RSI) will not cause blockage of nozzles on the spray ring of the CSP system and damage to the fuel rod support grid during the recirculation phase of the RSI system clogged.

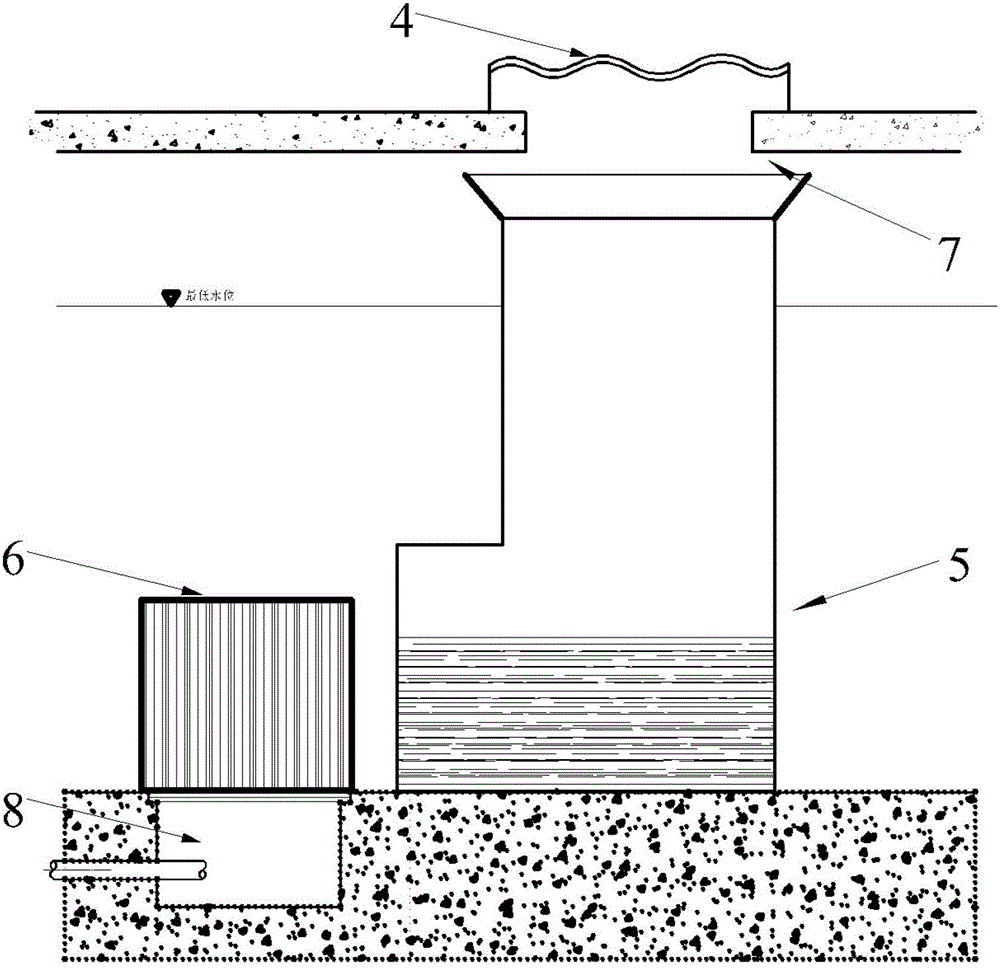

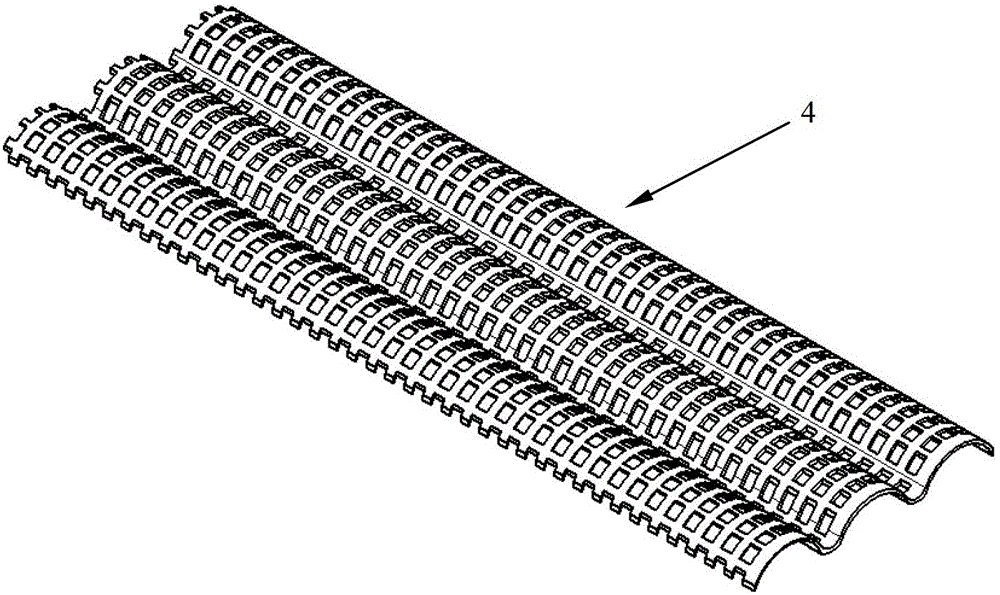

[0020] like figure 2 As shown, the filter system for the refueling water tank inside the containment provided by the present invention includes a trash rack 4 arranged above the hole 7 on the upper floor of the built-in refueling water tank, and an internal replacement rack 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com